According to a survey, the major driving force for drinking bottled water is a better taste and odor (51.3%), not its safety (34.2%) (March et al., 2020)! Increasing Dissolved Oxygen (DO) with aeration enhances the water quality in terms of aesthetic aspects such as taste and odor.

The concentration of DO in water resources relies on several factors. For instance, groundwater has a lower DO concentration than surface water since it is not in direct contact with the atmosphere. Higher temperatures and microbial activities can also reduce oxygen levels in the water (USGS, 2020).

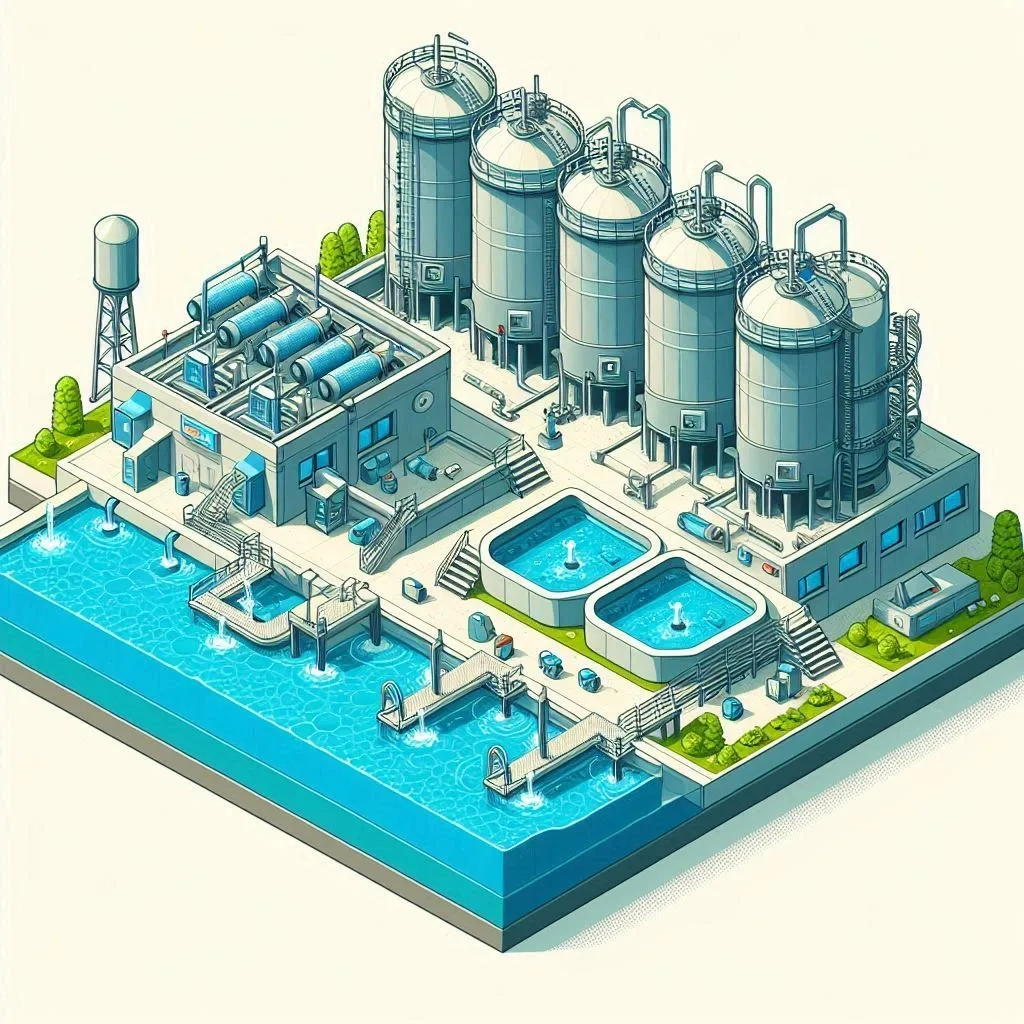

Aeration in water treatment is a method for increasing air and water contact. As a result of this process, some nuisance compounds are eliminated, which improves the taste and odor of drinking water. Aeration is considered to be a preliminary treatment before the main treatment processes (i.e., coagulation-flocculation, clarification, filtration, and disinfection) take place (Razali et al., 2023; Jasiwal and Goel, 2019).

In this article, we will explain the theory of aeration in water treatment systems. This process is applied for different purposes in water purification. Applications of aeration in water treatment will be explained as well. Different methods have been developed to add oxygen to the water. In the last section of this article, several types of aeration in water treatment will be introduced.

1. Theory of Aeration in Water Treatment

The theory of aeration in water treatment is based on gas transfer between liquid-gas phases. Aeration happens when water comes in close contact with the air. This process can be done for two reasons. First, to add a desirable gas such as oxygen to the water, and second, to release an unwanted gas such as hydrogen sulfide from the water. These two processes are called gas adsorption and air stripping, respectively (Kavanaugh and Trussell, 1980).

The driving force for gas transfer between air and water is the difference between the concentration of gas in water and its concentration in the equilibrium state. Based on Henry’s law, the amount of dissolved gas in a liquid is directly proportional to the partial pressure above the liquid. Henry’s law constant is the factor for this proportion, which varies based on the gas type and temperature. The solubility of gas decreases at higher temperatures (EPA, 1999).

The natural process of gas transfer and reaching equilibrium happens slowly. With aeration, a larger surface area of water is in contact with the air, which speeds up this process. If the concentration of gases in water is less than their equilibrium concentration, they are absorbed by the water. On the other hand, if the gas content in water is above the equilibrium concentration, it will be released into the atmosphere. Normally, the atmosphere does not contain volatile substances, so they will be removed from the water by aeration (Cox, 1964).

2. Applications

In the water purification process, aerators are used for various purposes. Some of the applications of aeration in water treatment are listed below (Haney, 1954; Krueger et al., 2020):

Removal of hydrogen sulfide and some organic volatile substances improves water in terms of taste and odor.

Reducing carbon dioxide concentration. Carbon dioxide is corrosive to pipes and equipment, and it reacts with chemicals used for water softening.

Removal of methane from water

Oxidization of iron, manganese, and some natural organic matter in the presence of oxygen

Sometimes carbon dioxide can also be added to the water for pH adjustment in the recarbonation process after water softens.

3. Types

Various types of aeration in water treatment plants are being used as a preliminary treatment for raw water, especially from groundwater resources. Some of them are introduced below:

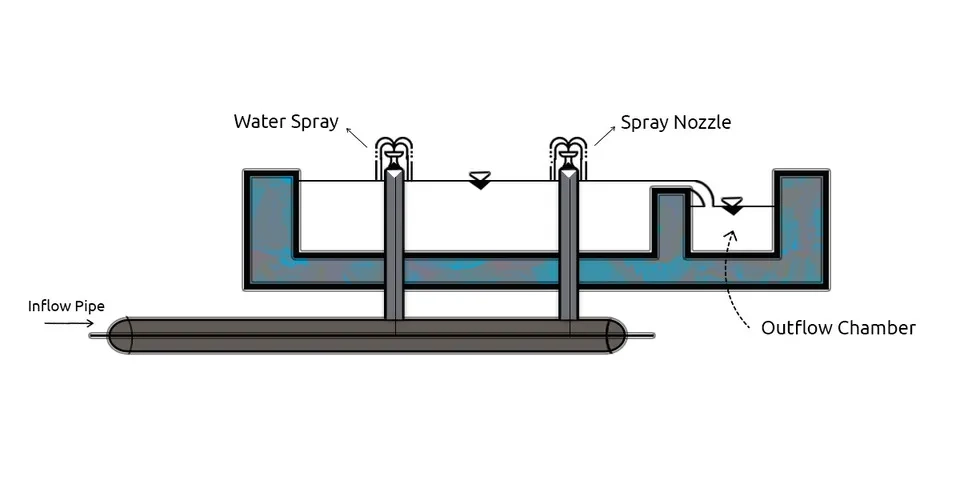

3.1. Spray Aerators

Spray aerators offer a high air-to-water ratio, and they are mostly operated in open basins since they require a large aeration area. In these aerators, water is sprayed into the air by nozzles that create water droplets. These small droplets have a large contact surface with the air when they fall. Spray aerators are more suitable for warm climates since they are prone to freezing in cold weather. Another drawback of spray aerators is clogging as a result of high levels of iron, manganese, and hardness in the water (Lytle et al., 1998).

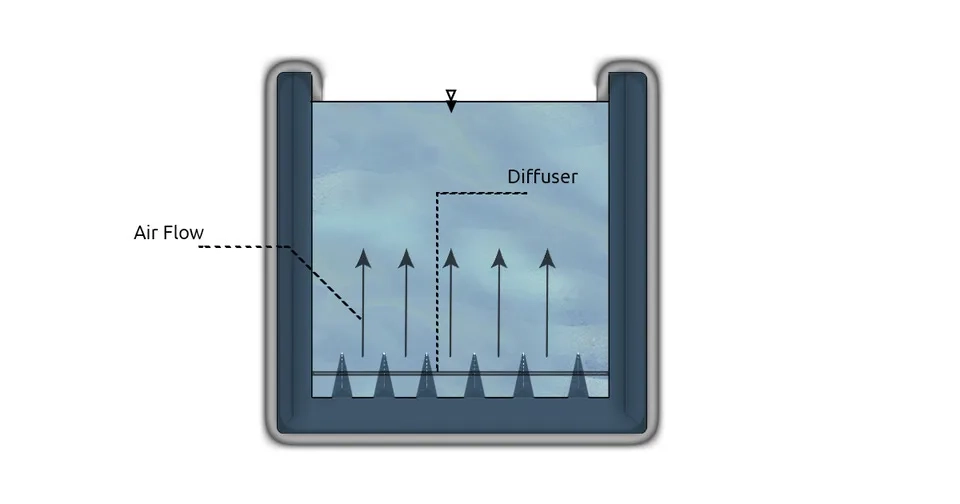

3.2. Diffused Air Aerator

In diffused air aerators, compressed air is injected into the water from the bottom of a rectangular tank through porous diffusers. The major advantage of this method is a better gas transfer between air and water due to the lower velocity of air bubbles compared to falling water drops. Unlike spray aerators, diffusers are not subject to freezing and can be operated in smaller spaces. However, they are more expensive than most aerators. A blower is needed to provide compressed air for these aerators, which results in increased operational and maintenance costs. The aeration time for this process is around 10 to 30 minutes (Scott et al., 1955; Puri et al., 2023).

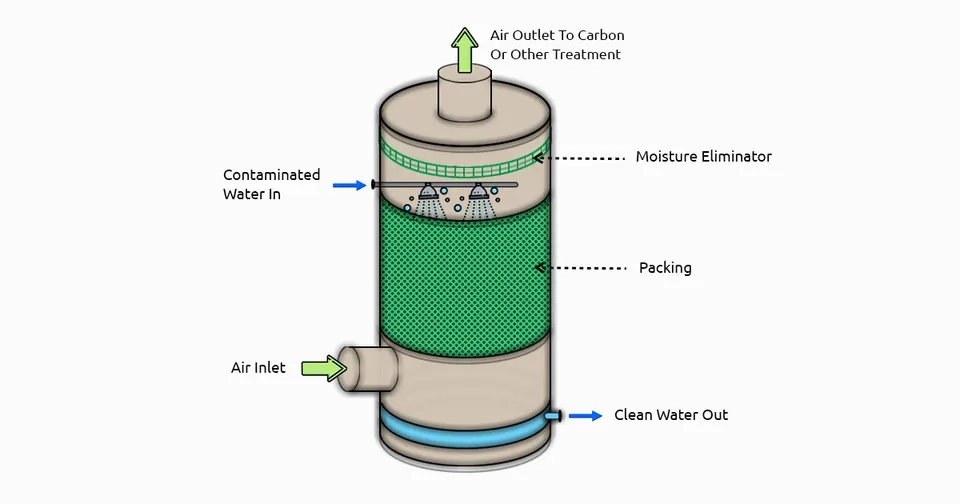

3.3. Packed Tower Aerator

Packed tower aerators consist of a cylindrical tower filled with packing media. This technique is used for removing volatile organic compounds by transferring them from the liquid phase to the gas phase. The water flows down the column, and packing media provide a large surface area for air and water contact. At the same time, air flows upward, and volatile substances are transferred to the gas phase. The efficiency of this method relies on the size and type of packing media (Bilello and Singley, 1986; Ghernaout, 2019).

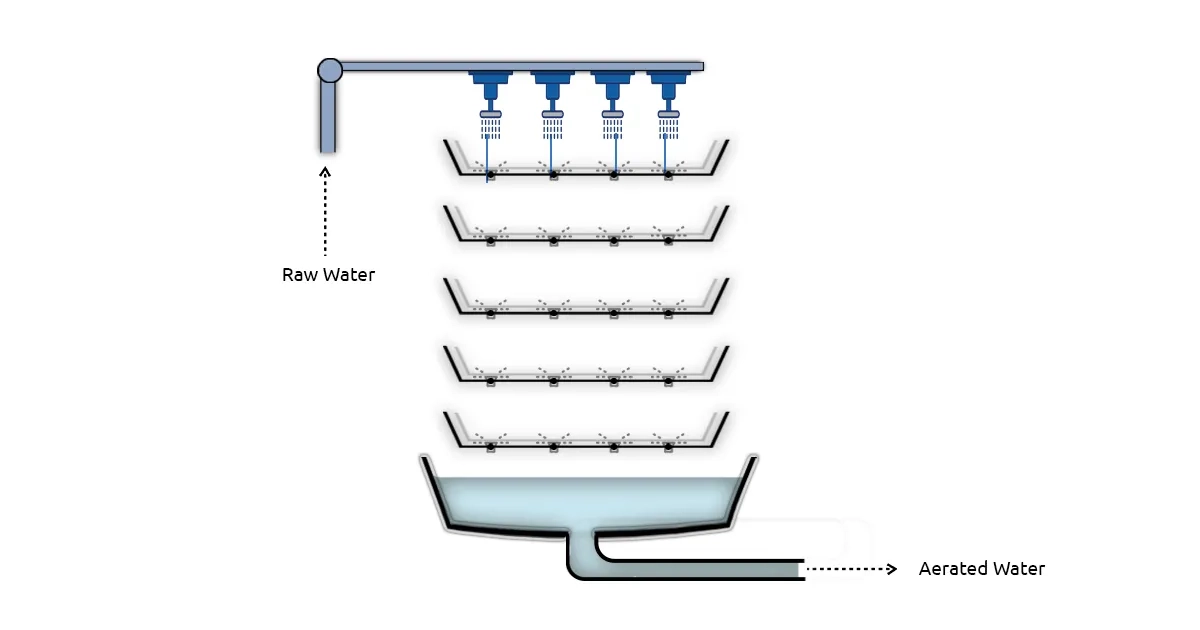

3.4. Multiple-Tray Aerator

Multiple-tray aerators consist of several trays placed on top of each other with a specified distance between them. These trays are made of flat sheets with some holes in each sheet that allow water to pass through them. Fine droplets of water form as water falls from one tray to another. This method is considered to be cheaper and easier to operate (Roy et al., 2020).

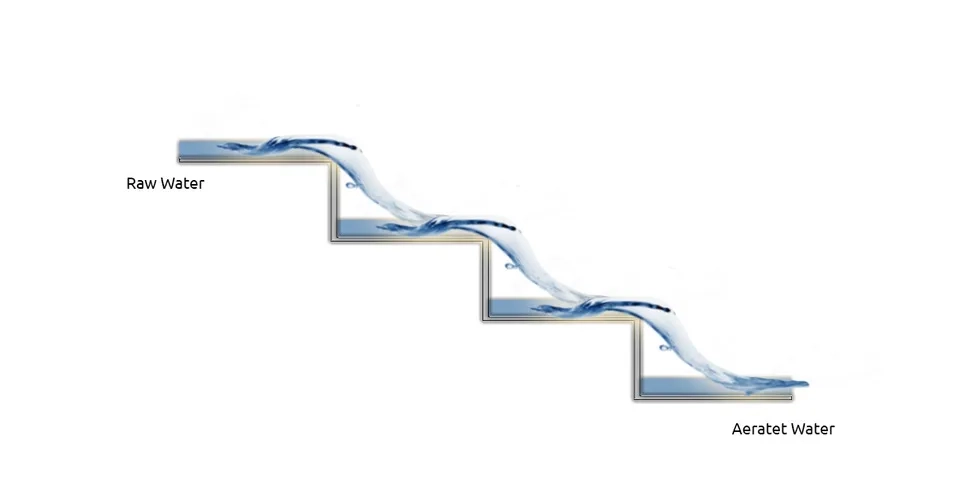

3.5. Cascade Aerator

A cascade aerator consists of several steps, and it works by gravity. Water flows down from one step to another through an overflow. A thin film of water is created by passing the water over the weir, which increases air and water contact and eliminates some contaminants from the water (Moulick et al., 2010).

4. Conclusion

Aeration in water treatment is a method for improving taste and odor by increasing the dissolved oxygen content of water and eliminating some contaminants (e.g., iron, manganese, volatile organic compounds, hydrogen sulfide, and carbon dioxide). Aeration is commonly used for groundwater since it contains low levels of DO. Several aeration methods have been developed, and each of them has advantages and disadvantages. The choice of method depends on many factors, including land limitations, climate, type of pollution, and available budget. For instance, diffused air aerators are more suitable for colder climates.