Various industries are nowadays facing the challenge of finding appropriate wastewater treatment technologies due to the increasing environmental awareness and stricter regulation standards. A combination of water and wastewater treatment methods is normally required to completely remove the contaminants from water (Renault et al., 2009). Among these, coagulation-flocculation is known to be one of the commonly used water treatment systems in industrial and urban applications due to its effectiveness, simplicity of operation and design, and low energy consumption (Almubaddal et al., 2009; Torres et al., 2009).

Generally, there are different types of coagulants in wastewater treatment which are obtained from natural (organic) or chemical (inorganic) sources and show potential application in treating water and wastewater. Both coagulants are capable of removing pollutants from water in the form of physical (suspended solids and turbidity) or chemical (COD and BOD). Each coagulant has its advantages and disadvantages and is capable of changing the physical state of dissolved and suspended solids to facilitate its removal from water and wastewater (Alexander et al., 2012).

Coagulant | Type of wastewater | Removal performance | Reference |

Alum | Paper mill industry | Turbidity: 97.1% COD: 92.7% | |

Moringa oleifera seed | Paper mill industry | Turbidity: 96.0% COD: 97.3% | Boulaadjoul et al., 2018 |

Ferric chloride | Paint industry | Color: 89.4% COD: 83.4% Turbidity: 88.5% | |

Cactus | Paint industry | Color: 88.4% COD: 78.2% Turbidity: 82.6% | Vishali and Karthikeyan, 2015 |

Alum | POME | TSS: 99.7% Turbidity: 98.7% COD: 75% Color: 94% | |

Chitosan | POME | TSS: 99% Turbidity: 98.4% COD: 68.3% Color: 96% | Jagaba et al., 2020 |

1. Coagulation-Flocculation

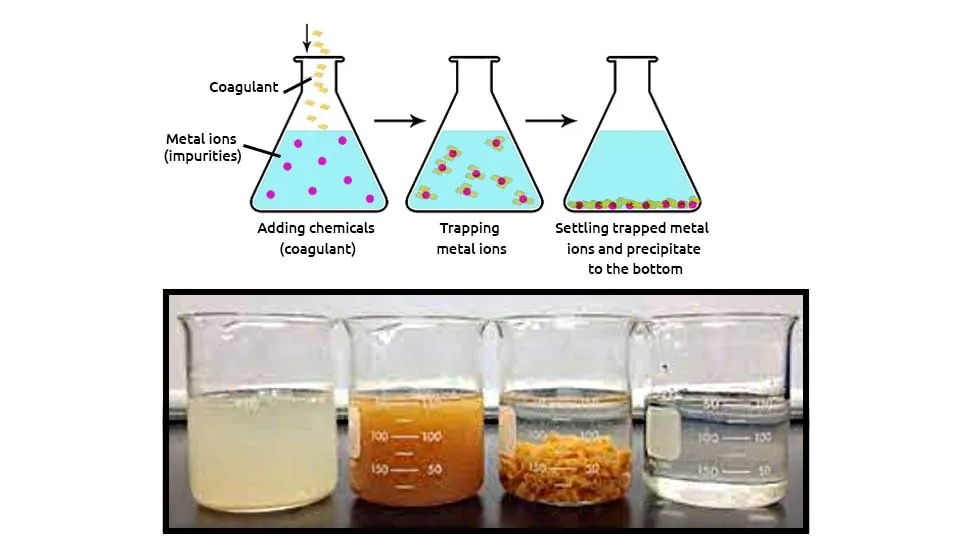

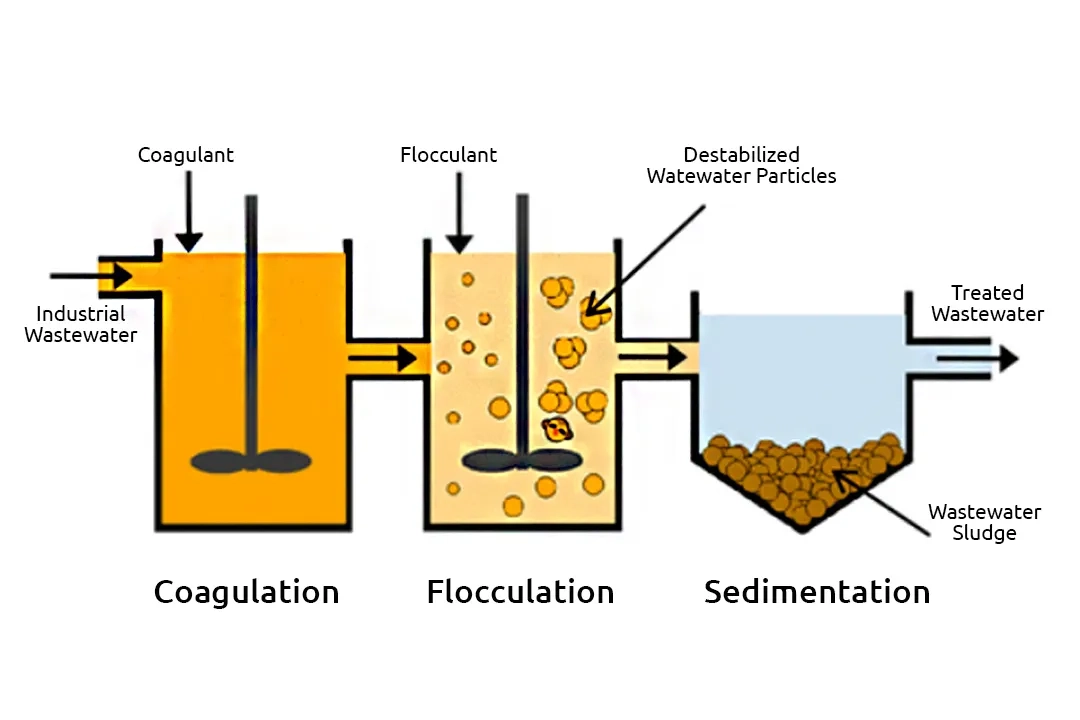

In domestic, industrial, municipal, and agricultural activities, wastewater is generated from the use of pure water. The main cause of increased wastewater production is population growth and urbanization. Several technologies have been developed in recent years to reduce the wastewater volume and control the risk of wastewater containing heavy metals to ultimately enhance the quality of recovered water. In particular, the coagulation-flocculation process is a prevalent purification method due to its effectiveness in removing insoluble pollutants and suspended particles (Kurniawan et al., 2006; Babel and Kurniawan, 2004) and is also addressed to agglomerate fine particles and colloids into larger particles to ultimately reduce turbidity, color, and organic and inorganic substances in the wastewater (Parson and Jefferson, 2006; Kakoi et al., 2016; Abidin et al., 2013).

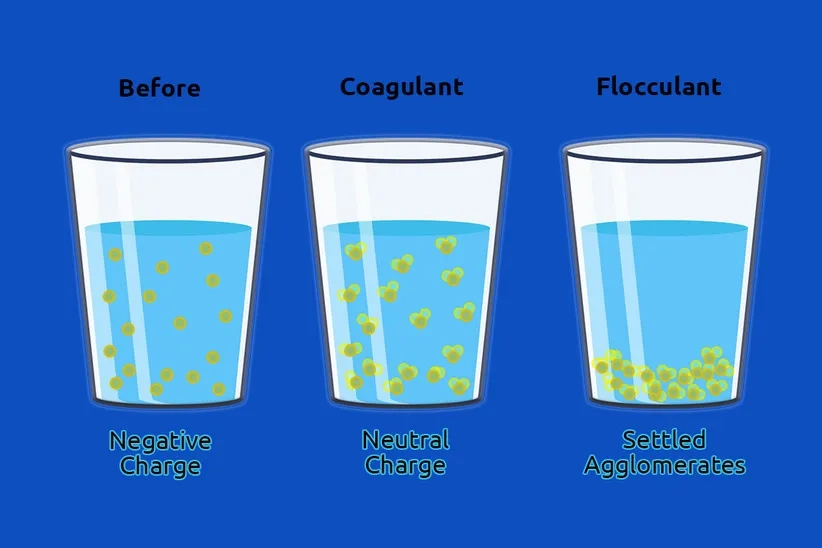

Generally, coagulation-flocculation consists of two main stages: (1) rapid mixing of coagulants into water or wastewater to be treated by violent agitation, and (2) flocculation by gentle agitation to agglomerate small particles into well-defined flocs. The flocs can finally be settled and removed in the form of sludge while the treated water/wastewater is transmitted into further treatment processes (Spellman, 2004). Coagulation is usually defined as the destabilization of suspension, leading to aggregation, and flocculation is defined as a process in which the destabilized particles are attached to form larger aggregates (Bratby, 2006; Gregory, 2005). In addition, coagulation-flocculation can be used in different treatment processes as a pre-treatment, post-treatment, and even as the main treatment of wastewater (Szyguła et al., 2009).

Table. Advantages and disadvantages of Coagulation-flocculation (Ang and Mohammad, 2020; Ariffin et al., 2017; Chethana et al., 2016)

Type of treatment | Advantages | Disadvantages |

Coagulation-flocculation | - Simple process - Good for reclamation or removal pollutants | - Require high dosage - Produce high sludge volume and large particles |

2. Selection of Coagulants

To select an appropriate coagulant for wastewater treatment, several factors should be considered including the nature of suspended solids, design of the treatment facility, raw wastewater condition, zeta potential, cost of coagulant chemicals, and Van der Waal’s forces. Jar testing or plant scale evaluation analysis is used to select the proper types of coagulants in the wastewater treatment process (Ukiwe et al., 2014). Since using the coagulants results in the colloidal particle’s aggregation, they grow into bigger size flocs and then settle down, which makes the separation process very easy. This process improves the treatment efficiency to achieve required industrial or drinking water standards. However, several factors can affect the coagulation process in water and wastewater treatment which are shown in the following table (Nath et al., 2021).

Table. Factors affecting the coagulation (Kumar et al., 2017)

Coagulant property | Effective characteristics | Properties of wastewater |

- Solubility of coagulants - Dosage of coagulants - Charge of coagulants - Basicity of a coagulant | - Settling and resolving time - Turbulence

- Amount of coagulant added - Particles type | - pH - Alkalinity - Availability of bacteria’s presence of Elements (Cl, Na, Mn, Si, Al, Fe, Fl, NH3) - TDS - SS - Temperature - Turbidity - DO |

TDS: Total Dissolved Solids

SS: Suspended Solids

DO: Dissolved Oxygen

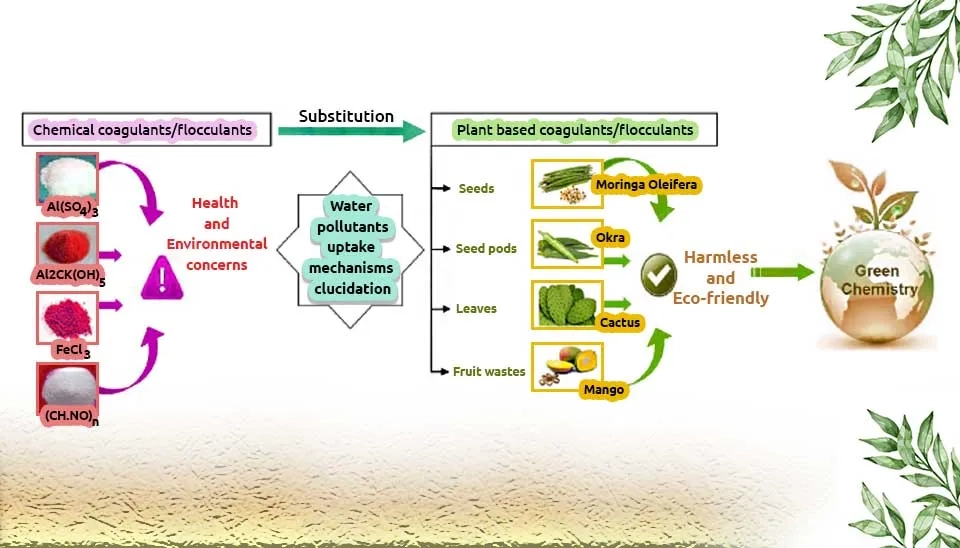

There are two main types of coagulants in wastewater treatment, including chemical and natural coagulants which have different treatment performances. According to (Bahrodin et al., 2021), it is highly recommended that chemical coagulants should be replaced with natural coagulants since their performance is much better in some cases. In addition, comparing the advantages and disadvantages of different types of coagulants shows that natural coagulants have a very good chance of being used as an alternative to chemical coagulants. In general, to minimize the environmental pollution and health risks caused by using chemical coagulants, it is better to use natural coagulants instead, since they have a biodegradable and environmentally friendly nature (Montuori et al., 2013). A critical review of the use of the main types of chemical and natural coagulants in wastewater treatment is provided in the following.

3. Chemical Coagulants

Wastewater includes several substances such as biological compounds, organic materials, and toxic inorganic pollutants which can have a negative impact on human health. A number of chemicals are usually used as coagulants for wastewater treatment (Nath et al., 2021). Chemical coagulants can be either polymers or inorganic metallic salts including aluminum sulfate, aluminum chloride, sodium aluminate, forms of polyaluminum chloride with organic polymers, ferric sulfate, ferric chloride, hydrated lime, magnesium carbonate, forms of ferric salts with organic polymers, etc. (Bratby, 2016). The most common chemical coagulants are discussed in the following.

CTA: For further information about chemical coagulants, click here.

Table. Advantages and disadvantages of chemical coagulants (Kumar et al., 2017)

Chemical coagulant | Advantages | Disadvantages |

Aluminum sulfate (Alum) | - Simple and easy to handle and apply - Producing less volume of sludge - Most effective between pH 6.5 and 7.5 | - Adds dissolved solids (salts) to water - Effective over a limited ph range |

Ferric chloride | - Effective between pH range 4-11 | - Adds dissolved solids (salts) to water - consumes twice as much alkalinity as alum |

Sodium aluminate | - Small dosage usually required - Can be used in hard water | - Normally used with alum - High cost - Ineffective in soft waters |

3.1. Metal Salt Coagulant

Metal salt coagulants are typically used in water and wastewater treatment plants which have many advantages over other types of coagulants. They have been proven to be very efficient in the removal of pollutants like Chemical Oxygen Demand (COD), heavy metals, turbidity, and Biological Oxygen Demand (BOD). Moreover, they are capable of bacteria inactivation. Due to the reasonable price and availability of metal salt coagulants, they are widely used in industrial wastewater treatment compared to other chemical coagulants. Aluminum-based and iron-based coagulants are two commonly used pre-polymerized inorganic coagulants in the market (Crini and Lichtfouse, 2019; Ukiwe et al., 2014).

3.1.1. Aluminum Sulfate and Ferric Chloride

The most conventional chemical coagulants used for water and wastewater treatment are known to be aluminum sulfate (Alum) and ferric chloride (FeCl3). When the coagulant is added to the water/wastewater, it will react through the hydrolysis process and the pollutants can be removed. Both iron-based and aluminum-based coagulants show good removal of pollutants. However, iron-based coagulants are cheaper, less sensitive to overdose, and have a wider pH range. As a result, the flocs formed by using iron-based coagulants are denser and tougher, making them more prone to breaking (Jagaba et al., 2020).

3.1.2. Sodium Aluminate

Sodium aluminate (NaAlO2) is typically used as a viscous and corrosive liquid. This coagulant is alkaline rather than acidic, making it distinct from alum. For example, alum with acid is usually used during the coagulation of colored waters at low pH. This leads to an undesirable concentration of soluble aluminum compounds. Therefore, alkaline sodium aluminate can be added to the water to increase the pH (at least 6.0), making the soluble aluminum to participate in a secondary settling basin (Bratby, 2016).

3.2. pre-polymeric inorganic coagulants

Significant progress has been made in the development of highly efficient pre-polymerized inorganic coagulants. During the last two decades, pre-polymerized inorganic coagulants like Poly-Aluminum Chloride (PAC), Poly-Aluminum Sulfate (PAS), and Poly-Aluminum Chloro-Sulfate (PACS) have been widely used around the world. These coagulants are more advantageous than conventional chemical coagulants due to their ability to function efficiently and properly at a wide range of pH, water temperature, and colloid concentration ranges (Jiang, 1997). New-generation inorganic coagulants like pre-hyrolized Fe/Al salts are efficient, more effective, and cost-effective (Aguilar et al., 2003; Kushwaha et al., 2010). Tzoupanos and Zouboulis (Tzoupanou and Zouboulis, 2008) also found that using silica in the form of poly-silicate is an advanced coagulation method for inorganic and organic matter and pathogens removal from water and wastewater. To read more about product descriptions and buy pre-polymerized inorganic coagulants, click here.

3.2.1. Activated silica

Polyelectrolytes are known to be special classes of polymers with certain functional groups on the polymer backbone that can be ionizable. One of the most common polyelectrolytes used in water clarification is activated silica. A drawback of using this chemical is that silica gel may form when the concentration of reagents, degree of neutralization, mixing degree, and aging are not properly controlled during its preparation method. Therefore, using activated silica usually leads to a reduction in filter runs and blockages in feed pipes and pumps (Bratby, 2016).

4. Natural Coagulants

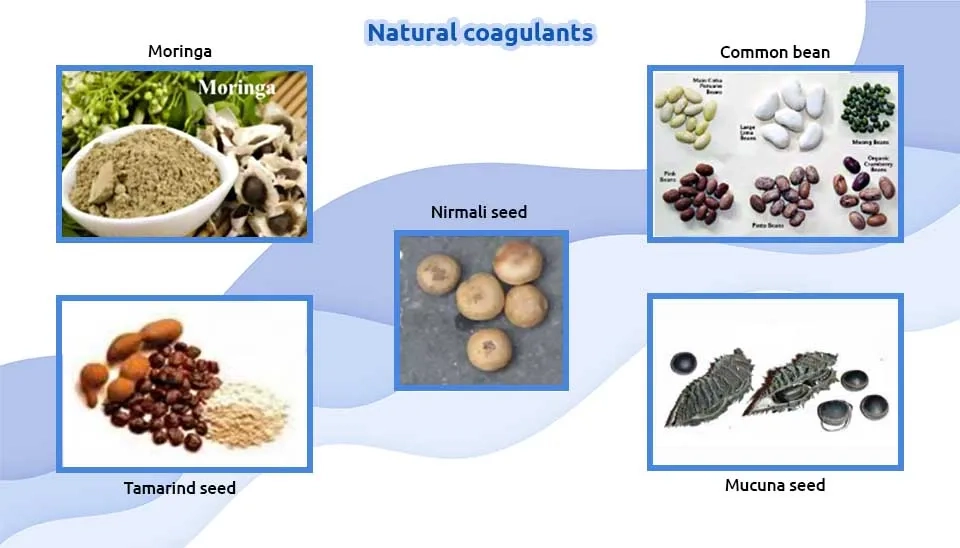

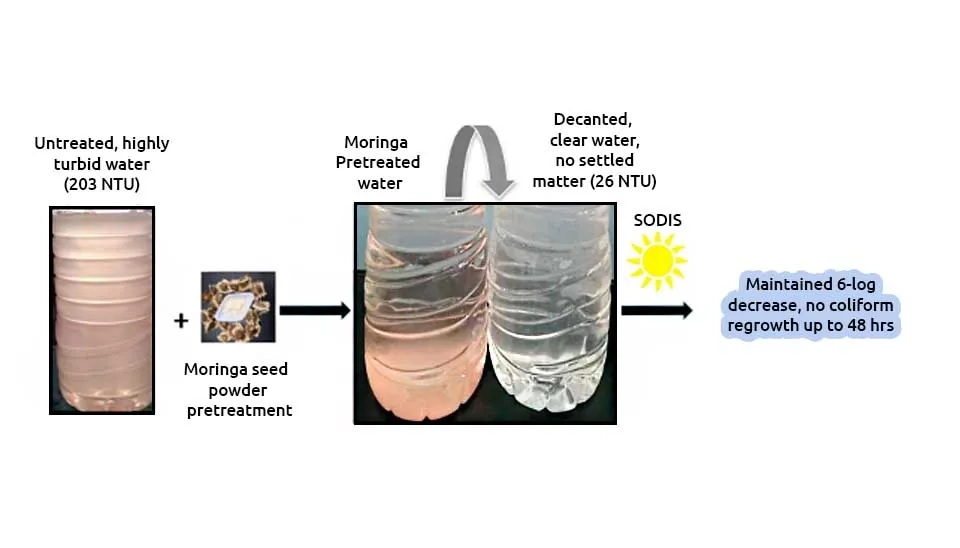

Several studies have been carried out on different sources which can be used as natural coagulants. Natural coagulants can be obtained from plant-based (e.g. cactus) or animal-based (e.g. chitosan) sources. The process of treating using a natural coagulant consisting of molecules bridging, adsorption, and balancing the charge. Natural coagulants can treat the wastewater following the effluent discharge standards. Unlike chemical coagulants that can affect the environment, or cause neurological and pathological disorders, natural coagulants are an environmentally friendly green product and harmless for human health (Rajendran et al., 2015; Othmani et al., 2020).

Moreover, in recent years, the application of natural coagulants has been growing rapidly, since it has a low impact on pH and fast reaction. However, the high price of plant-based coagulants is known to be a drawback that makes them inefficient in industrial-scale treatment (Litu et al., 2019; Nath et al., 2021). According to previous studies, plant-based coagulants were capable of removing 60-98% turbidity, 80-91% fecal coliform, and 55-89% organic content without prior extraction and purification (Alwi et al., 2013; Balamurugan and Shunmugapriya, 2019). Common natural coagulants are discussed in the following.

Table. Efficiency of natural coagulants (Kumar et al., 2017)

Natural coagulant | Turbidity | COD |

Moringa oleifera | 82.02% | 83.33% |

Cactus | 78.54% | 80.65% |

4.1. Moringa Oleifera

In particular, waste from plant-based sources is mostly used as a natural coagulant. To determine which part of the plant is a suitable and potential natural coagulant, every part of the plant from stem to leaf should be tested (Arafat and Mohamed, 2013; Balamurugan and Shunmugapriya, 2019).

One of the most established natural coagulants is known to be Moringa oleifera. Its application has been approved in various types of water and wastewater treatment including dairy wastewater (Pallavi and Mahesh, 2013). Moringa oleifera is a non-hazardous (at low concentration) stifling plant whose seeds contain an edible oil and also some substances that are soluble in water (Okuda et al., 2001).

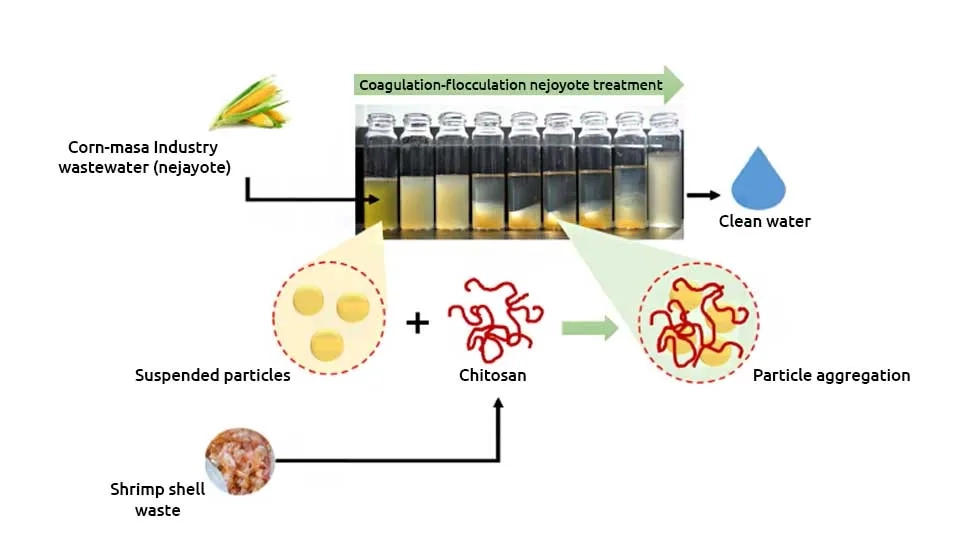

4.2. Chitosan

Chitosan is a naturally occurring amino-polysaccharide with a hydrophilic nature. Due to its biodegradability, eco-friendly and non-toxic nature, efficiency in adsorbing a variety of metal ions, and unique physicochemical characteristics because of the presence of amino groups in the polymeric chain and high nitrogen content, there is a wide application of chitosan in recent decades. It is produced by the chitin’s deacetylation which is the second most common biopolymer after cellulose. The chitosan is an animal-based coagulant that can be obtained from the oceanic invertebrates, yeasts, fungi, and insects. It is mainly used in dye/textile wastewater and Palm Oil Mill Effluent (POME) treatment but its strong chelation and adsorption properties also make it highly effective for pharmaceutical wastewater treatment where persistent micropollutants are a major concern (Yin, 2010; Szyguła et al., 2008).

4.3. Cactus

For treating wastewater, some varieties of cactus can be used. One of the cactus species that is normally used as a natural coagulant is Opentia latifaria (Rebah and Siddeeg, 2017). There are mucilage materials in the cactus that contain substances such as d-galactose, d-xyloose, l-arabinose, and galacturonic acid. During the coagulation process, these compounds are responsible for bridging action. Galacturonic acid is one the most important materials that is capable of removing approximately 50% of turbidity in water treatment (Sáenz et al., 2004; Miller et al., 2008). Cofloc coagulant is a non-toxic, biodegradable, and low-molecular-weight polymer which is produced from cactus plants (Czerwionka et al., 2020).

5. Advantages and Disadvantages

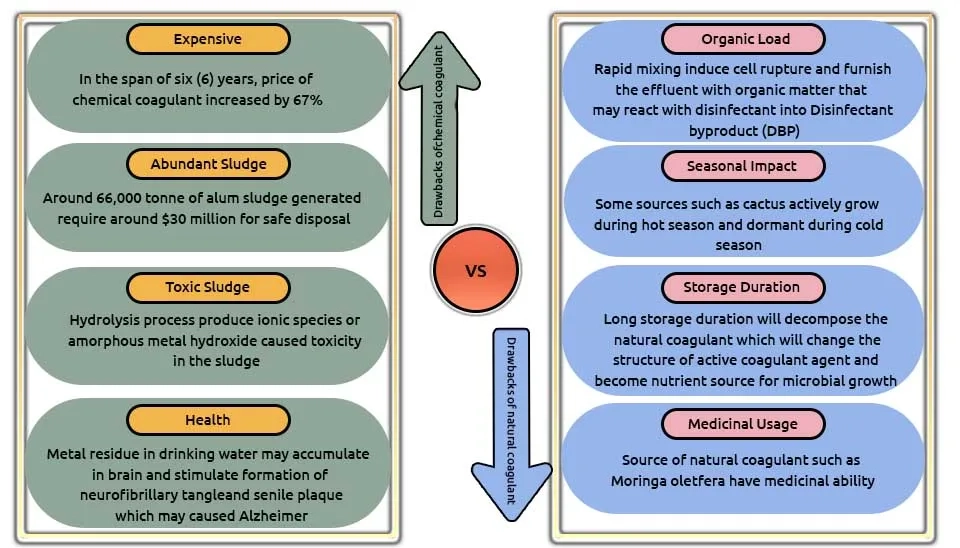

In terms of removal of various pollutants in water and wastewater treatment, chemical coagulants as well as natural coagulants show almost similar efficiency. Nevertheless, just like other treatment alternatives, the disadvantages are inevitable. Natural resources have become very interesting for researchers due to their numerous advantages. They produce less sludge volume and are relatively cheaper than chemical substances (Hadibarata et al., 2018; Syafiuddin et al., 2020).

chemical coagulants have negative impacts on health and the environment and are more serious and long-lasting since these coagulants like aluminum sulfate and ferric chloride affect people’s health due to long consumption of water, which may cause neurodegenerative disease, and also affect the environment in terms of toxic sludge generation (Montuori et al., 2013; De Pippo et al., 2006). On the other hand, the disadvantages of natural coagulants are mainly related to their nature like the impact of seasons and storage duration, which may affect the production and supply of the natural coagulant (Syafiuddin and Fulazzaky, 2021; Mahmud et al., 2021). Another drawback of natural coagulants is the negative impacts on the environment in terms of releasing organic contents into the treated effluent and thereby increasing the levels of COD, BOD, and TOC concentrations. However, by associating extraction and purification processes such as acid and alkali, the environmental drawbacks of natural coagulants can be decreased, which is almost impossible for chemical coagulants (Bahrodin et al., 2021).

6. Conclusion

In this paper, we described different types of coagulants in wastewater treatment. Coagulants are primarily used for the improvement of several parameters in treated wastewater. Using different coagulants is a very efficient way to remove pollutants from the water and to obtain the desirable water and wastewater quality according to standards. Due to their purpose and application, both natural and chemical coagulants have advantages and disadvantages. However, due to the eco-friendly and biodegradable nature of plant-based or animal-based coagulants, the utilization of natural coagulants is a promising technology in water and wastewater treatment. Furthermore, unlike chemical coagulants, natural coagulants have no adverse impact on human health and do not alter the physico-chemical characteristics of treated water. To sum up, the transition from chemical to natural coagulant may be an alternative solution to minimize health risks and environmental pollution, as well as promote green technologies in water and wastewater treatment industries.