The depletion of the world's water resources is becoming a pressing concern. This is a terrifying situation for the planet, but there are many ways to tackle this problem. Instead of wishing for more rain or limiting essential consumption, generated wastewater can be treated and come back to the consumption cycle. Industrial production of goods and services is at the top of our modern economy and accounts for approximately 20% of global water consumption (FAO, 2020). The growth in population and industry has increased water consumption rapidly, which also results in imposing a major threat to water resources, as industries are the largest consumers of freshwater. As water consumption increases, so does the generation of wastewater. While the industrial sector accounts for only about 3% of freshwater withdrawals, it generates approximately 16% of wastewater. These numbers indicate the importance of industrial wastewater treatment. However, only 20% of industrial wastewater receives global treatment. The remaining wastewater is discharged without treatment, leading to health hazards and other issues (UNESCO, 2012).

Industrial wastewater should be treated properly to keep the environment safe. The primary objectives of this process are to separate solid and harmless materials that could have adverse environmental impacts and subsequently reuse the treated wastewater and residual materials for various purposes. There are various methods employed for effective industrial wastewater treatment. The common treatment techniques include pretreatment, primary treatment, secondary treatment, and disinfection. It's important to note that the principles of industrial wastewater treatment vary for each industry due to their distinct constituents. Hence, industrial wastewater treatment technology is diverse (Roy et al., 2022).

1. Types of Industrial Wastewater

Industrial wastewater has a high diversity in quality and substance depending on the industry and its production methods (Walling et al., 2022). The common contaminants for industrial wastewater are divided into three categories, which will be explained in the following paragraphs.

1.1. Heavy Metal Wastewater

Heavy metals are those metals that have very high density and are highly poisonous, even at low concentrations. These heavy metals include Mercury (Hg), Cadmium (Cd), Arsenic (As), Chromium (Cr), Thallium (Tl), Zinc (Zn), Nickel (Ni), Copper (Cu), and Lead (Pb). Municipal wastewater, industrial wastewater, landfill leachate, mining waste, and urban runoff are the main sources of contamination (Abd Elnabi et al., 2023). Industries are the major source of heavy metals in wastewater, such as The electroplating industry, which contains a significant number of metals like Cd, Zn, Pb, Cr, Ni, C, Ag, Pd, and titanium; the wood processing industry; the paint industry; the enameling industry; etc. (Palani et al., 2021).

1.2. Nitrogen Wastewater

Nitrogen ends up in the environment mainly through agricultural processes and as industrial wastewater from coloring production, oil refining, organic chemicals, glass manufacturing, feed production, chemical fertilizer, meat processing, animal husbandry, the pharmaceutical industry, and other industries (Tabassum et al., 2018). It is a requirement for all organisms and plants because it contains all proteins and nucleic acids. On the other hand, nitrogen compounds in the environment cause concern due to their potential harmful effects. As an example, nitrate (nitrogen in a reactive form) exposed to the environment can be a risk to human and ecosystem health (Mohamed et al., 2022).

1.3. Oily Wastewater

Oily wastewater is defined as industrial wastewater that consists of fats, oils, and greases coupled with a variety of dissolved substances (organic and inorganic) in suspension at high concentrations (Wei et al., 2020). It is mostly produced by different industries, such as metal processing industries, restaurants, slaughterhouses, dairy industries, poultry processing industries, edible oil refineries, petrochemical industries, tannery industries, etc. (Kuyukina et al., 2020; Sanghmitra et al., 2021). This type of wastewater is harmful to human health and can cause diseases such as cancer; in addition, it is capable of contaminating drinking water and groundwater resources as well. It may also increase chemical and biological oxygen demands in water bodies, exerting different impacts on aquatic ecosystems (Yu et al., 2017; Putatunda et al., 2019).

2. Types of Industrial Wastewater Treatment

Industrial wastewater is usually collected from municipal and industrial drainage systems, and treatment facilities process it via various methods to separate different types of waste. Wastewater can also be stored inside the industrial units in closed-top frac tanks before transporting it to the processing facility (Wilson, 2021). But before transferring, effective industrial wastewater treatment should be identified; this is because any type of industrial wastewater has a specific type of treatment technology. Therefore, it is essential to understand different types of industrial wastewater treatment technologies and their recent trends. According to the types of industrial wastewater that were mentioned above, there are different treatments for each type that are explained in the following paragraphs.

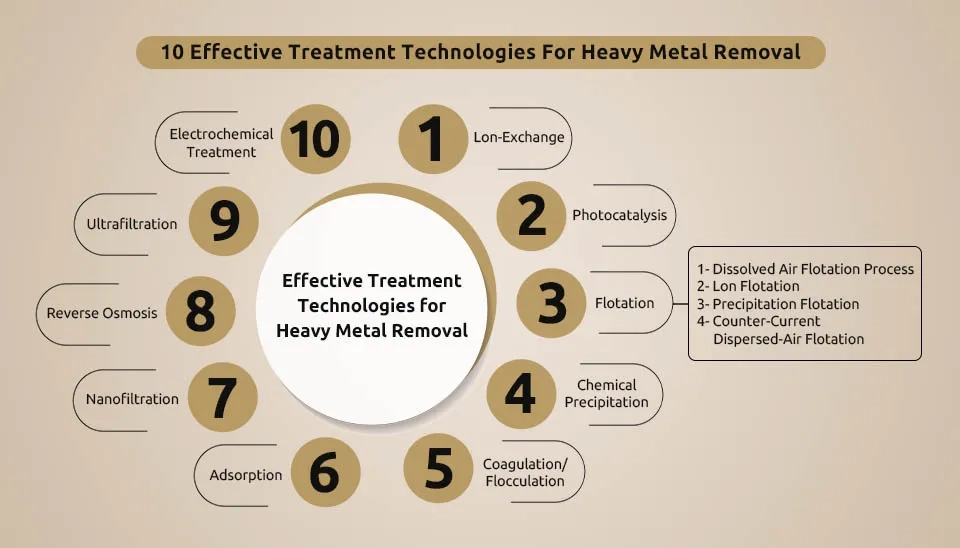

2.1. Heavy Metal Wastewater Treatment

We implement numerous principles to recover heavy metal wastewater and achieve metal-free status. Choosing a suitable technology for treatment depends upon its efficiency in the removal of heavy metal ions of As, Cd, Cr, Cu, Pb, and Hg forever (Saleh et al., 2021). According to recent studies, there are 10 effective treatment technologies for heavy metal removal, which are shown below.

These technologies are employed with the aim of efficient metal removal and recovery. The removal findings are different for each process in terms of experimental conditions and removal efficiency percentages. Generally, most of these technologies have acceptable removal percentages according to the type and conditions in which heavy metal ions exist. Currently, photocatalysis stands out as one of the most innovative technologies for heavy metal wastewater treatment. (Shrestha et al., 2021). This promising technology is characterized by the advantage of having strong oxidizing power, being capable of destroying heavy metal complexes and freeing them from the metal ions, and, meanwhile, being capable of oxidizing and degrading organic complexes (Alansi et al., 2021; Li et al., 2021).

2.2. Nitrogen Wastewater Treatment

The removal of Nitrogen compounds, specifically NH3 and NH4+, comes with some advantages and limitations as well (Zhou et al., 2023). The most common methods for treating nitrogen in wastewater include Precipitation, Adsorption, and Biological processes. Precipitation has been trendy in wastewater nitrogen removal (denitrification) in recent years mostly due to its simple and convenient operation. Adsorption is another popular method in wastewater denitrification. Its primary advantages include efficient removal, low energy consumption, and ease of operation. It is especially suitable for treating wastewater with low concentrations of NH4+. Among all of these technologies, the biological method is more practical for denitrification due to the following advantages: (1) high denitrification efficiency, which means it can remove most of the organic nitrogen and ammonia nitrogen in industrial wastewater; (2) low cost, low investment, and simple process; and (3) removal of multiple pollutants at the same time, which can lower organic compounds such as phenol, cyanide, and COD while denitrifying (Hasan et al., 2021).

2.3. Oily Wastewater Treatment

Researchers have been developing the use of novel low-cost technologies and materials for the optimization of separation processes using multidisciplinary approaches (Abuhasel et al., 2021). The implementation of innovative technologies for oily wastewater treatment provides efficient methods and techniques to remove these pollutants. In certain scenarios, the utilization of combined technologies becomes necessary for comprehensive treatment (Adetunji and Olaniran, 2021).

Consider the potential of novel biotechnological solutions, notably the utilization of bacterial cellulose as a membrane in separation processes, which has the advantage of reusability and sustainable process insurance. Additionally, AOPs show promise due to their capacity to treat oily wastewater rapidly and without generating secondary pollution. (Medeiros et al., 2022).

3. Conclusion

This study is performed based on understanding different types of advanced industrial wastewater treatment and their recent trends and technologies. The objective is to urge governmental bodies to significantly decrease untreated wastewater discharge while concurrently promoting eco-friendly recycling and reuse. Hence, selecting effective industrial wastewater treatment technologies is pivotal for achieving this. It must be considered that treatment principles are chosen based on types of wastewater pollutants. According to the study, there are 3 main types of heavy metal wastewater, nitrogen wastewater, and oily wastewater. When released into the environment without treatment, these pollutants pose dangerous hazards and jeopardize the environment's safety and health. Professionals in water treatment utilize various technologies, combining some to achieve the necessary results. After doing much research, it is concluded that the most promising technologies for heavy metal, nitrogen, and oily pollutant removal are photocatalysis, biological processes, and biotechnological solutions, respectively. Overall, it is beneficial to know that the transformation and conversion of industrial wastewater into reusable water and valuable products by applying suitable technologies would lead to a more effective approach to industrial wastewater management.