Water shortages and pollution have become two major concerns for humankind, as many people still do not have access to safe drinking water. According to the World Health Organization, in 2020, only 74% of the world’s population had access to clean water, while over 2 billion people were using drinking water contaminated with feces! Unsafe water can cause waterborne diseases such as diarrhea, typhoid fever, and hepatitis A (WHO, 2022). Thus, it is important to develop efficient technologies in the water industry that are capable of removing pathogens as well as other contaminants (e.g., nitrate, arsenic, pesticides, heavy metals, and disinfection-byproducts). These technologies should be cost-effective and environment-friendly in addition to producing high-quality water for human consumption.

The membrane filtration technique is a reliable method, and it has been used for decades in the water industry. In the 1960s, the membrane separation process started to grow as an emerging technology for separating particles from the liquid phase or gas phase in various industrial applications. Membrane technology has made an important impact on human life, and despite all the progress made in this area, there is still room for development (Fane et al. 2010).

This article will discuss the principles of membrane filtration and explain two separation processes employed in these filters. Then, four main types of membrane filters (i.e., microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) will be briefly introduced along with their applications in water treatment and other industries. Finally, we will discuss the pros and cons of this technology.

1. Principles of Membrane Filtration

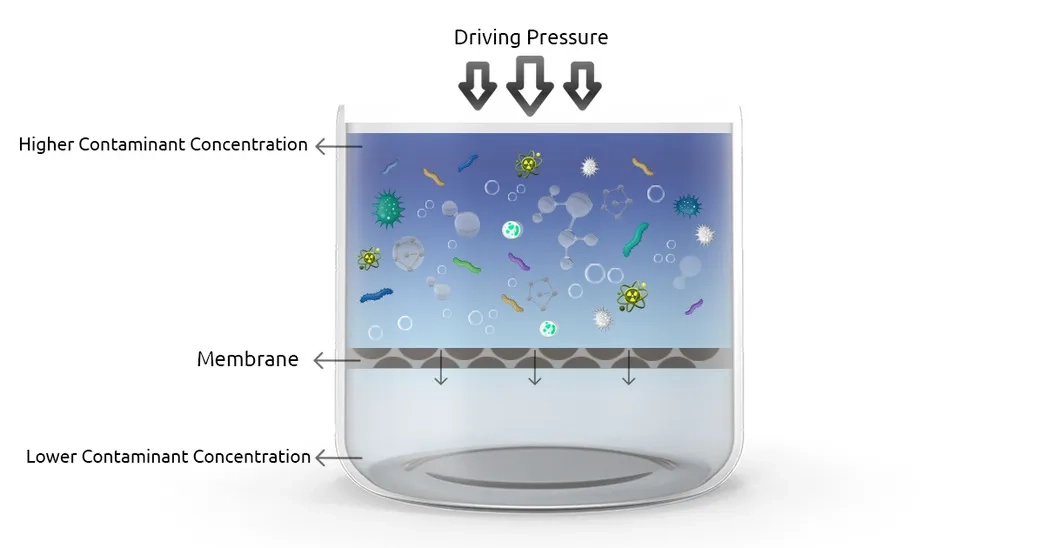

What is a membrane? A membrane is a thin layer between two different phases that selectively allows materials to transport through these phases. This semi-permeable barrier can be organic or inorganic. In this process, applied pressure works as a driving force for water molecules to pass through the membrane while contaminants get rejected. After filtration, feed water divides into two streams: filtrate (or permeate) and concentrate (or retentate). Filtrate is defined as the freshwater passed through the membrane, while concentrate includes the particles ejected from feed water. The efficiency of particle removal is mostly associated with membrane pore size. Smaller pore sizes result in a higher rejection rate while requiring more pressure (Obotey Ezugbe and Rathilal, 2020; Peters, 2010).

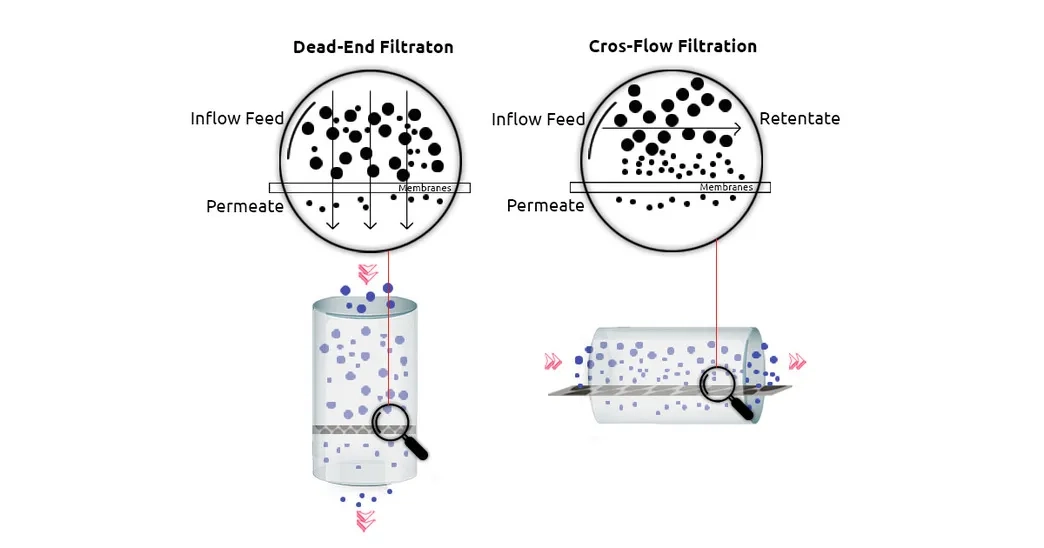

2. Filtration Modes: Dead-end and Cross-flow

Filters can operate in two different modes. In dead-end filtration, the flow is perpendicular to the membrane; as a result, the particles accumulate on the membrane and form a cake layer over time, which reduces the filter’s efficiency. Cross-flow is an improved form of filtration where the inflow is parallel to the membrane surface. In this mode, the cake layer is thinner because some of the particles exit along with the retentate flow (Abdel-Fatah, 2018).

3. Four Types of Membrane Filtration

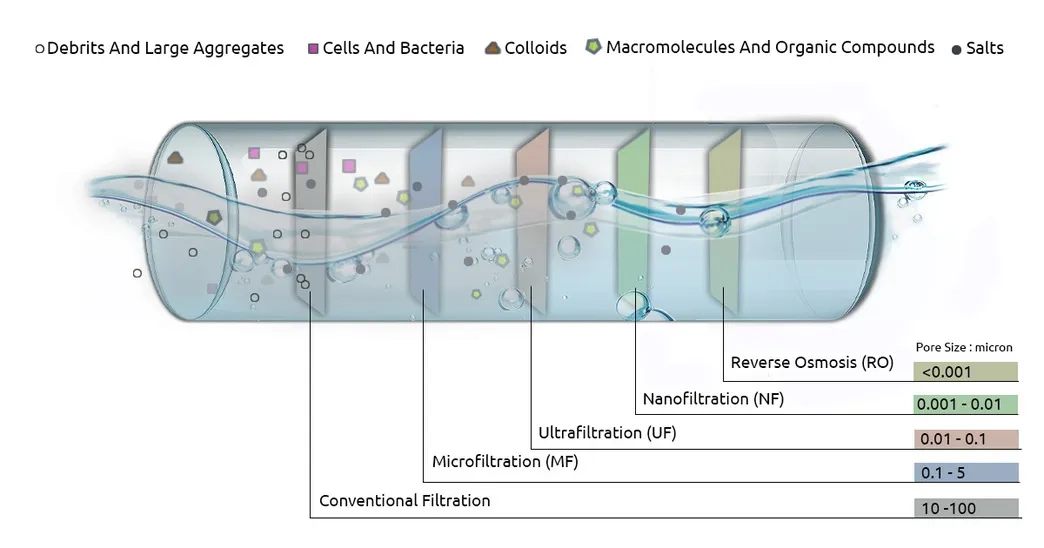

Membrane filters are categorized into four main types including MicroFiltration (MF), UltraFiltration (UF), NanoFiltration (NF), and Reverse Osmosis (RO) (Chao et al., 2018).

3.1. Microfiltration

Microfilters have the largest pores among these four types. Their pore size ranges from 0.1 to 5 microns, and they are capable of removing large contaminants such as particles, cells, and bacteria from water. Although it has applications in the food and pharmaceutical industries, microfiltration technology main application is in wastewater treatment (Anis et al., 2019).

3.2. Ultrafiltration

Ultrafilters are similar to microfilters with smaller pore diameters (0.1-0.01 microns); therefore, ultrafiltration technology can reject smaller contaminants, such as viruses, that can not be removed by MF filters (Oatley-Radcliffe et al., 2017).

3.3. Nanofiltration

In NF, the rejection rate is somewhere between the RO and UF membranes. Water softening is their major application in water treatment, and nanofiltration technology can eliminate matter ranging from 0.01 to 0.001 microns (e.g., divalent ions, most organic salts, and viruses) (Lee et al., 2016).

3.4. Reverse Osmosis (RO)

Reverse osmosis is the most popular method for treating brackish water. RO filters are used in more than 50% of desalination plants. RO membranes have the tightest pores among these 4 types of membranes, with less than 1 nm in size (Hailemariam et al., 2020).

4. Applications of Membrane Filtration

Membrane filters are commonly used in municipal and industrial wastewater treatment . This technology can be used in water treatment plants and also on a smaller scale at the consumption point to improve water quality (Madaeni, 1999).

In addition to water purification, membranes are used in various industrial areas. Some of them are listed below (Hakami et al., 2020):

Medicine and Pharmaceuticals

Food, beverage, and dairy

Chemicals and petrochemicals

Pulp and paper

Textile

5. Advantages and Disadvantages

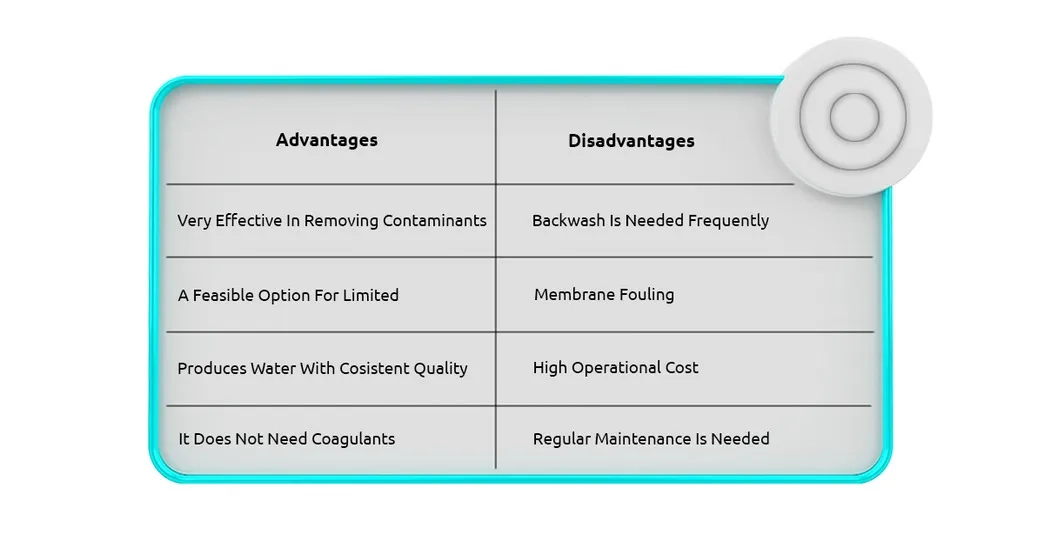

Unlike conventional water treatment, membrane filters can consistently produce high-quality water without the need for a coagulation-flocculation process. On the other hand, relatively higher operational costs and membrane fouling are two important challenges in membrane filtration.

The following are the advantages and disadvantages of this technology (Othman et al. 2022):

6. Conclusion

As we are facing an increase in water consumption and emerging contaminants, new technologies need to be developed as a solution. Membrane filtration has proven to be a prominent method in the water industry. Compared to conventional water treatment, membrane filters offer higher water quality and occupy less space. Membrane plants are widely used for the desalination of seawater in water-stressed countries. Even though it has been used on a large scale for almost 60 years, there are still issues that need to be addressed. High capital costs and membrane fouling are two major problems with this technique. Numerous studies are being conducted in this field, which may result in further advancements in the future.