The sludge treatment process, which counts the operating and management cost as up to 60 % of overall expenditure, has been one of the major challenges in WasteWater Treatment Plants (WWTPs). High sludge treatment costs have disadvantages for WWTPs, in particular smaller ones. In practice, small WWTPs may transport sludge to large wastewater treatment plants instead of building their own sludge treatment plants, which would increase transport costs (Uggetti et al., 2009).

Sludge is a solid material produced from wastewater treatment for the purpose of processing and, in fact, plays an important role in this process (Demirbas et al., 2017). Due to its high nutrient content, sludge produced from WWTP may be used as fertilizers or soil conditioners in agriculture and forestry. However, sludge has advantageous nutrients for plants and modifying properties for the soil, it may also contain bacteria, viruses, protozoa, parasites, and other disease-causing organisms as well as heavy metals and organic compounds such as Polychlorinated Biphenyls (PCBs) and pesticides that may pose harmful impacts to crops, animals, humans, and the environment (Udayanga et al., 2018). The issue of microplastics in sludge produced by wastewater treatment plants, together with other pollutants, has attracted the attention of scientists in recent years, who have claimed that the widespread use of sludge in agriculture and forestry could be a major source of microplastics entering the environment (Dris et al., 2015).

It is necessary to treat wastewater sludge before it can be used as soil amendments or fertilizer, with a view to reducing its water content and odor, inactivating the pathogenic organisms, and preventing biodegradation. Anaerobic digestion, composting and stabilization with alkaline materials or other chemical substances, thermal treatment by heat drying, pyrolysis, etc. are some of the treatments that can be used (Turunen et al., 2018). Treatment changes sludge's physical characteristics, and the quality and feasibility of a finished sludge product can be affected.

1. Wastewater Sludge Pollutants

Some components of wastewater may be able to increase their concentration in sludge while they are passing through the sewage treatment system. Although there may be fertilizing characteristics for certain organic and mineral components of the sludge, they could not have been desirable because of their associated health and environmental risks (Fijalkowski et al., 2017). In general, these undesirable constituents are grouped into the following categories:

Heavy Metals

Trace Organic Contaminants

Pathogenic Organisms

Depending upon the characteristics of raw wastewater and on the treatment system, their presence in sludge is extremely variable. The sewage from healthy populations contains significantly less pathogens than those originating in the unhealthful population. In a similar way, sludge from household wastewater has low content of heavy metals which are usually harmless to the environment. The release of industrial waste to a sewage system is the main source of chemical contaminants in sludge (Styszko et al., 2022).

1.1. Heavy Metals

Although heavy metals may eventually be toxic to plants and animals, chronic toxicity due to their disposal is not usually reported, even in the low concentrations normally found in domestic wastewater. On the other hand, since industrial wastewater is a major source of concentrated heavy metals, this is not the case with the disposal of industrial wastewater and, in particular, its sludge. In view of all the various influence factors, heavy metal concentrations in sludge are highly variable from place to place (Buaisha et al., 2020).

1.2. Trace Organic Contaminants

Chemical manufacturing, plastic manufacture, chemical products, Mechanical Products, Pharmaceutical Industry, Pesticide Manufacturing, Casthouse and Steel Industries, Oil and laundries, etc are the major sources of Organic Compounds. In industrial effluents, the most common organic pollutants include cyanide, phenol, methyl chloride, toluene, ethyl benzene, trichloroethylene, tetrachloroethylene, chloroform, etc (Díaz et al., 2020).

1.3. Pathogenic Organisms

Organisms that are known to exist in sludge may include saprophytes, commensals, symbionts, or parasites. In humans and animals, only parasites are pathogenic and capable of causing disease. Five groups of pathogenic organisms that can be found in sludge consist of (a) helminths, (b) protozoa, (c) fungi, (d) viruses, (e) bacteria.

The pathogenic organisms might come from human sources, taking into account the population's health status as well as hygiene levels in the region. They may also come from animal sources, whose droppings are eliminated through the water-borne sewerage system (dog and cat feces), or else through vectors in sewers, mainly rodents. In terms of pathogens in sludge, epidemiological studies have shown that bacteria, viruses, helminth eggs, and protozoan cysts pose a risk to human and animal health (Li et al., 2022).

2. Wastewater Sludge Treatment Processes

A major factor in the design and operation of all wastewater treatment plants is the treatment and disposal of sewage sludge. A reduction in volume and stabilization of organic materials are the main objectives for treating sludge before final disposal. Stabilized sludges do not have a smell of offensiveness, and can be processed without creating any nuisance or health hazards. Additionally, the cost of pumping and storage will be reduced by a smaller volume of sludge (Nathason, 2020).

A combination of different processes are used to treat wastewater sludge properly such as thickening, digestion, and dewatering processes. Hence, in the following paragraphs, different sewage sludge treatment processes and their mechanisms are introduced for better efficiency in WWTPs.

2.1. Anaerobic Digestion

In the treatment of different organic wastes, including sludge from sewage systems, anaerobic digestion is generally considered to be an efficient and environmentally friendly technology. During the absence of oxygen, there is a biological degradation in organic waste and it has been converted into biogas or other energy-rich organic compounds as end products. In the generation of energy, it is possible to use biogas containing between 48% and 65% methane (Nasir et al., 2012).

Anaerobic digestion is an established method for treating sewage sludge without any pretreatment, and it is effective in terms of removal of high water content sewage sludge (Ward et al., 2008). Anaerobic digestion improves the stabilization of sewage sludge, reduces pathogens and odor emissions, and reduces the dry matter of sludge, which leads to a significant reduction in the final sludge volume. It is widely known that anaerobic digestion of sewage sludge provides these benefits, and technologies are well established in many countries.

It must be noted that the majority of biogas produced by anaerobic digestion plants is generated from sites in water treatment and wastewater treatment plants which has led to an essential role for anaerobic digestion in today's WWTP. Anaerobic co-digestion, where one or more substrates are mixed and broken down at the same time, has also been introduced in this trend (Braun & Wellinger, 2009).

2.2. Dewatering

In order to produce dense and concentrated sludge, this technique of treatment uses removal of water content from sludge. This process has been described as essential and suitable for the management of solid waste because it can increase bioenergy use, reduce sludge volumes and help transport and also reduce landfill waste (Wang et al., 2016). It is challenging to apply this process on sludge, due to the highly hydrated colloidal structures of microbial aggregates, which are present in sludge properties. Fenton oxidation, microwave technique, alkali and acid preconditioning, ultrasound processing, advanced oxidation process, flocculation, sonication, biology, or electrolysing technologies lead to increased sludge dewaterability (Bei Li et al., 2021). There are some differences between dewatering and thickening. Thickening removes substantially more water from the sludge to generate a concentrated sludge product with a concentration of sludge dewatering, often between 15% and 25%. The former removes free water, raising the dry solid content to 4–6%, and the execution of the technique process is where the second difference lies (Kamizela & Kowalczyk, 2019).

The use of the sludge dewatering process is a very difficult and high-cost part of the treatment process, but also an environmentally sound method as it's made from organically produced substances such as flocculants. This floc is composed of microbial aggregates and their Extracellular Polymeric Substances (EPS), which appear in different layers such as loosely bound, tightly bound, and slime. The EPS is responsible for the functioning integrity, structure, porosity, separate surface area, and filtration resistance of aggregates (Dai et al., 2018).

2.3. Compostation

Composting is the preferred method for neutralizing sewage sludge. It involves a complicated process and is aimed at the destruction of pathogenic organisms; Stabilization of organic matter; Drying of the sludge; and Production of material that may be environmentally has either been used or sold. Sludge must be mixed with structural materials in a proper proportion to achieve these objectives. The most commonly used structural material is cellulose, such as wood shavings, sawdust, bark, straw, and leaf litter. The transformation occurring during the composting of materials containing cellulose with the sludge has enzymatic character. Composting also uses municipal waste, for example, scraps of elastic tires (Oleszkiewicz et al., 1998).

The organic matter is degraded anaerobically in the process of composting. Sludge composting aims at stabilizing biologically recoverable organics, eliminating pathogenic organisms, and reducing the volume of waste. During composting organic matter is subjected to biological degradation and, as a result, it has been reduced by 20% to 30% of volatile solids (Bharathiraja et al. 2014).

In composting anaerobic bacteria remove most of the organic matter to carbon dioxide, leaving a relatively stable odorless substance that can be used as fertilizer. The final product is stable and can be applied as a soil conditioner in the agriculture sector. Compared to anaerobic composting, aerobic composting is more commonly used. The major advantage of this compost is that it is a very good fertilizer, but it is not much used yet. Phosphorus and potassium have a very high fertilizer content in sewage sludge (Li et al., 2012).

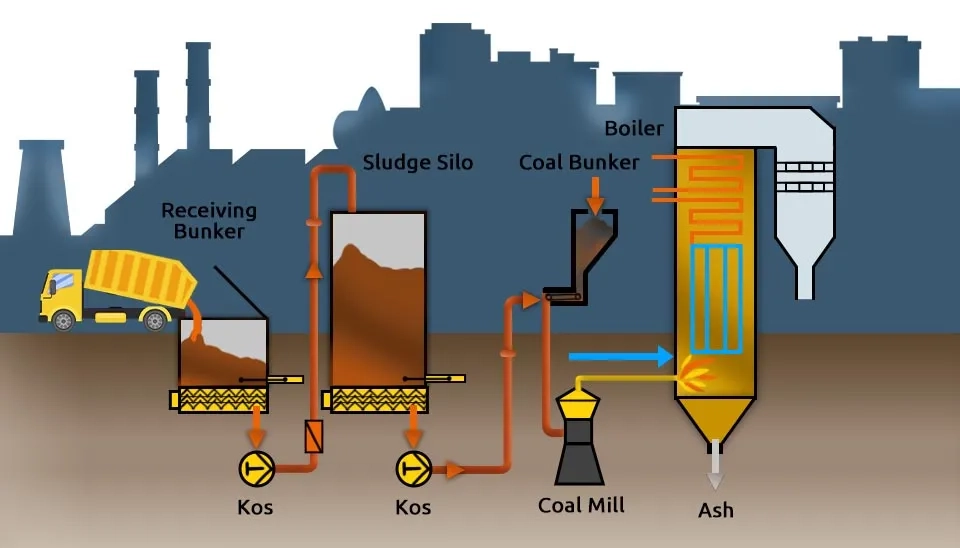

2.4. Incineration

Complete oxidation of organic compounds at a high temperature is the primary purpose of sludge incineration. with excess air (oxygen) to form mainly carbon dioxide and water, leaving only inert material (ash). Recently, incineration of sewage sludge was the most commonly performed and globally accepted treatment route. Today, large sludge incinerators are still in operation to generate electricity and to convert sludge into ash, and oxidative processes are also used to convert nitrogen, organic carbon, phosphorus, and sulfur into gaseous form. In most developed countries, it is the best alternative technology for the treatment and disposal of sludge due to its large volume reduction, pathogen reduction, odor reduction, and energy production (Liang et al., 2021).

This method is, however, not the best treatment technique for sludge because around 30% of it continues to be ash (Chen et al., 2003). In most cases, due to the high levels of toxic heavy metals, the ash is disposed of in the landfill and is considered to be harmful to the surrounding area, leading to contamination of groundwater. Besides, another limitation use of this method is gas emission pollutants, such as non-methane volatile organic materials, nitrogen oxides, and sulfur dioxide. Ammonia emissions are generated as a result of sludge incineration and have been an important nutrient for the production of crops, as well as contributing to nitrogen pollution by acidification and eutrophication (Wielgosin ́ski et al., 2016 , Eiof Jonson et al., 2019). Whenever acid deposition increases, lakes, oceans, and soil become supersaturated with nutrients which harms marine ecosystem deforestation and denaturation of plants. Therefore, the incineration treatment process was found unsuitable for sludge treatment. Nowadays, there have been advanced engineered incinerators with high air pollution abatement competence and resource recovery capability (Murawska et al., 2021). In particular, given their impact on air pollution and global climate change, it is essential that these technologies are subject to economic and societal scrutiny.

2.5. Carbonization

This technology is widely known as HydroThermal Carbonization (HTC), which converts organic matter into high-carbon material (hydraulic char) and small amounts of hydraulic oil and syngaS a certain temperature and pressure for a certain period. HTC has attracted more attention because it accelerates the hydrophobic sludge dehydration process, producing high biochar yields (can be used in agriculture as organic fertilizer, pH regulator, and deodorizer). inhibitors such as ammonia nitrogen in anaerobic digestion and other functional materials (Wang et al., 2019).

In addition, carbon is influenced by the raw organic matter and hydrothermal parameters such as temperature and time. The process is economical, as it does not require pretreatment and requires minimal energy consumption. Furthermore, it is possible to use hydrocharmethane as a solid fuel source to replace fossil fuels and thus reduce NOx emissions by producing volatile nitrogen during the combustion process which can be upgraded with ammonia NH3, hence reducing NOx emissions when used as an energy source (Zhao et al., 2013). However, HTC is not capable of removing heavy metal from the sludge (Liu et al., 2018).

-Process-677c0b86f11e374e33d3845b)

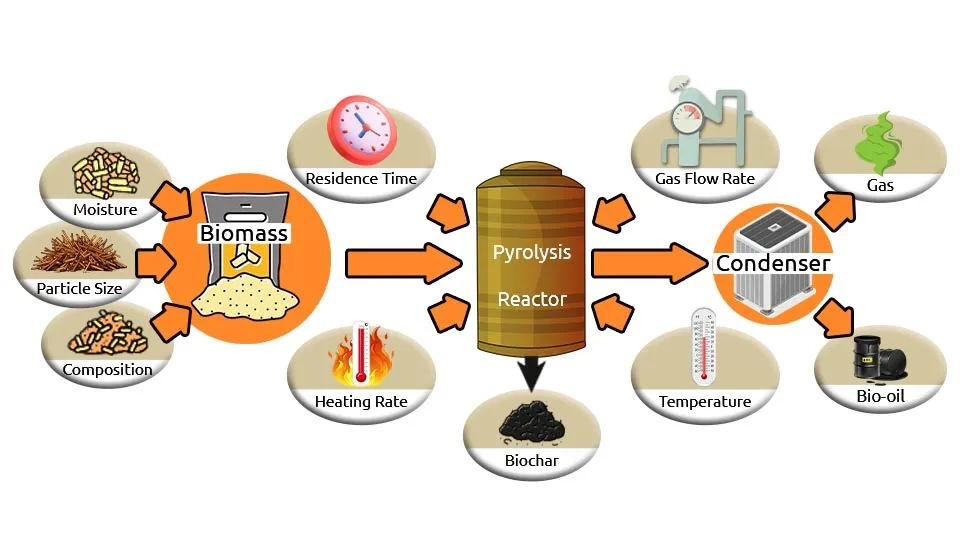

2.6. Pyrolysis

In recent years the process of pyrolysis has become more and more known, thanks to its environmentally friendly nature and ability to turn biomass into three main product types: Bio-oil, Biomass Energy or Syngas. It is a thermal procedure that takes place without oxygen. All products of pyrolysis are effective and useful in a wide range of applications. Biochar can be used to increase biogas generation when it is added as fuel for anaerobic digestion (Qiu et al., 2019). However, ammonia nitrogen, sulfide, limonene, volatile fatty acids, long-chain fatty acids, and pH may be inhibited by anaerobic digestion. Biochar can be used to modify these inhibitors to stabilize the functioning of anaerobic digesters, thus increasing the production of biogas as a key product of this process. As this product contains the most valuable compound for plant growth, it is capable of improving soil properties (Staˇs et al., 2020). Nevertheless, the most suitable technique of sludge treatment seems to be pyrolysis; this method has some limitations in terms of heavy metals that contain substances . All residues of biodiesel, bio-oil, and syngas have been confirmed to include heavy metals following the pyrolysis process. Heavy metals transportation via different applications of pyrolysis byproducts was feasible (Larina et al., 2020). The combination of pyrolysis and acid washing has resulted in a low environmental risk for resource use (Li et al., 2023).

2.7. Drying

Currently, the main problems faced by reinsurers are finding an economy, recycling, and environmentally responsible ways of managing social security. Solar drying is typically used to treat sludge around the world due to its natural, affordable, and ability to destroy pathogens such as helminth eggs(An-nori et al., 2021). It's going to reduce the volume of sludge and be a source of renewable energy as well. In the context of managing a WWTP, drying sludge in view of its large operational costs and ecological concerns has been becoming an indispensable process. The production of biosolids yields economic value and may be used for other purposes, such as fertilizers or fuel to incinerators, etc.; instead of being discarded. For the development of the drying process, knowledge of the drying kinetics is essential (Gomes et al., 2023). This process, however, has some limitations, for example, it is subject to climate fluctuations and unstable temperatures in large areas with high risks of adoration and emission of harmful gasses during the operation.

2.8. Wet Oxidation

Wet oxidation is a hydrothermal process in which organic and inorganic materials are oxidized at a certain temperature and pressure range of approximately 150 to 270 °C and 30 to 250 bar, respectively, and by maintaining high pressure in the liquid phase, the oxidation degree is increased (Chung et al., 2009). This method consists of a complicated process that is broken into two major phases, such as mass flows from the gas phase to the liquid phase and chemical reactions between dissolved oxygen and matrix; Carbonrich material, which can be used instead of methanol for denitrification, is the effluent from wet oxidation treatment. Moreover, since its furans, dioxins, sulfur dioxide, and nitrogen oxides are free of emissions, this method is considered as a new alternative to incineration. In the area of sludge treatment, chemical, pharmaceutical, and petrochemical plants, approximately 200 wet oxidation industries are currently under construction. Even though the thermal treatment did not release any dangerous gas inside the environment, it was insufficiently effective at treating sludge. This process allows the capture of toxic heavy metals (Nickel and Vanadium) in the effluent due to the partial carbon conversion of the thermal treatment (Zhang, 2020 , Collivignarelli et al., 2018).

2.9. Microwave Irradiation

Microwave irradiation occurs at frequencies of 300 MHz to 300 GHz with a corresponding wavelength of 1 mm-1 m within the electronic spectrum. The irradiation of MW is considered a promising alternative to conventional heating methods. In wastewater and wastewater sludge treatment, during microwave irradiation, the destruction of microorganisms and other molecules may occur in two ways: thermal and athermal (non-thermal) effects.

Thermal effects are generated via ionic conduction (in shorter frequencies) and dipole rotation (in higher frequencies) the former means the electrophoretic (conductive) migration of dissolved ions in the electromagnetic field (Neas & Collins, 1988), while the latter is generated through the rotation of dipole molecules (like water) due to the constant and repeated changes in the polarity of the field (Verma et al., 2020). Athermal effects are induced by the change in dipole orientation of certain polar molecules, which increase the possibility of breaking down the hydrogen bonds of biopolymers (polysaccharides, proteins, Deoxyribonucleic acid (DNA), Ribonucleic acid (RNA). For industrial applications, the frequency of 915 MHz is the most favorable, as shorter frequencies have a higher penetration depth, which increases the thermal and athermal effects (Morte et al., 2020).

The amount of biogas produced from sludge may also be increased by the use of a single microwave irradiation. A promising method for treating wastewater and sewage sludges may also be the combination of microwave irradiation with ultrasonication. Although the benefits of microwave and ultrasonic treatment for biodegradability and increased biogas production from sludge have been established, further studies are still required to explore their applicability in technologies targeting non-kinetic use of sludge. Another important area for research is microwave and ultrasound-assisted processes to extract valuable non-organic compounds of municipal or industrial sludge, according to the circular economy concept (Yeneneh et al., 2013).

2.10. Electron Beam Irradiation

Electron beam treatment has been proven to be a successful approach to the disinfection of both wastewater and sewage sludge. Nevertheless, before 2000, there were concerns about the perceived high capital costs of the accelerator and with public acceptance of the usage of radiation for water treatment purposes (Kurucz et al., 1995 , Tobian et al., 2000). Nowadays, with increased knowledge and technological development, it may be not only possible but also desirable to use electron beam technology for risk-free sewage sludge treatment, disposal, and bio-friendly fertilizer production. In this technique, different types of electron beam accelerators are used, and the microbicidal action of ionizing radiation is achieved through direct and indirect effects. The concentration of contaminants and the pH of the solution influence the effectiveness of the treatment. Additionally, the presence of specific compounds in sewage sludge affects the treatment process as well. The energy of the applied electrons determines the penetration depth and the optimal depth for treatment (Hossain et al., 2018).

The electron beam facility needs to be designed with sufficient electron beam power and high electron beam utilization capacity, as well as high accelerator electrical efficiency, to reduce unit operation cost and increase productivity along with possibly low electron energy for capital and operation cost reduction (Chao et al., 2017).

The most important benefits of the electron beam sewage sludge treatment system are the possibility of removing various pollutants at the same time by both oxidation and reduction, low exploitation costs, the eco-friendly character of technology, and the unit cost decrease along with the increase of the throughput and sludge biodegradability improvement. The most important disadvantages of the electron beam sewage sludge treatment are electron penetration limit and appropriate material distribution (Siwek & Edgecock, 2020).

3. Conclusion

In this article, the main objective was to explore different sludge treatment processes and explain 10 different methods for wastewater or sewage sludge treatment. Some of these methods are already used in WWTPs based on their objectives in the usage of sludge treatment products such as anaerobic digestion, carbonization, dewatering, wet oxidation, incineration, composting, and drying. On the other hand, some of the treatment processes are more advanced, cost-effective, and environmentally friendly like electron beam irradiation, microwave irradiation, and pyrolysis. Therefore, it is essential to alternate usual methods with newer techniques. Moreover, the combination of these processes also enhances the efficiency of sludge treatment in WWTPs.

All in all, wastewater or sewage sludge treatment processes have 2 major aims which are: 1) Usage of treated sludge as fertilizer and 2) Generation of electricity and fuel substitute. The combination of processes is based on fulfilling these objectives and obtaining the proper efficiency.