Have you ever calculated the difference between the amount of water initially diverted into the canal network and the amount ultimately delivered to your agricultural land at designated points? You may not believe it, but it can be significant!

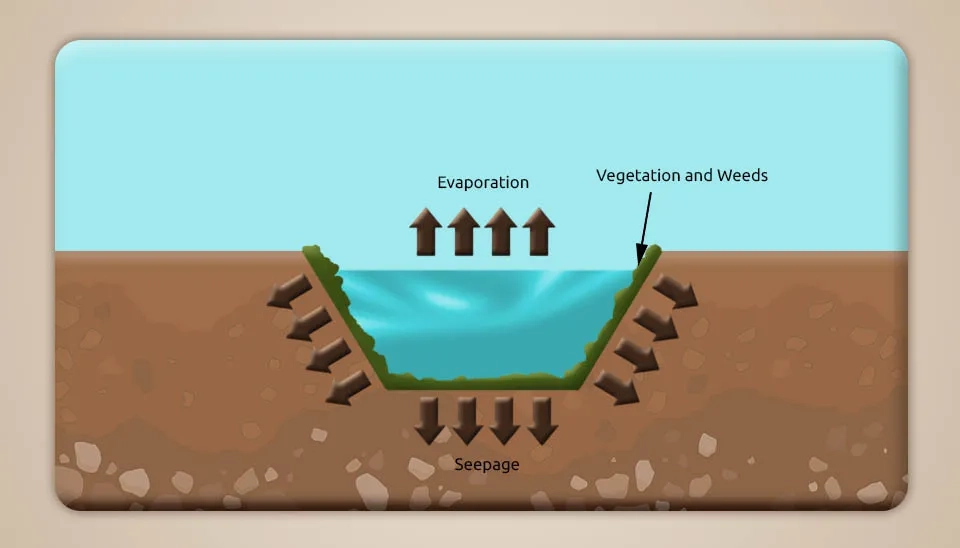

Water loss in irrigation canals presents a significant challenge in agricultural water distribution systems with major consequences for resource management and sustainability. Estimates indicate that water loss in irrigation canals may reach up to 50%, which worsens issues of water scarcity, economic costs, and environmental consequences (Clemente et al., 2013). Water is primarily lost through seepage, operational issues, and evaporation. Seepage losses occur when water escapes through an earthen canal structure or degraded lining, which results in a high infiltration rate that depends on soil composition and permeability. Operational losses stem from the inefficient use of hydraulic structures, such as water level regulators and off-take structures, which disrupt the reliable delivery of water users (Karimi Avargani et al., 2023). In comparison, evaporation losses are minimal compared to seepage and operational losses but do contribute to overall water reduction (Akkuzu, 2012). Seepage loss is particularly concerning in canals built in permeable soils, while canals built on clay-rich soils experience lower seepage due to reduced permeability (Mutema and Dhavu, 2022). Taking solutions to reduce water loss in irrigation canals is crucial for enhancing water use efficiency and achieving sustainable irrigation practices, which are discussed thoroughly in this article.

Table 1. Solutions to Reduce Water Loss in Irrigation Canals (brief table)

Solution | Advantages |

Training, Maintenance, and Performance Optimization | - Reduces unstable hydraulic conditions and unnecessary losses - Ensures timely regulation of off-take structures - Improves accountability and transparency within operating companies - Bridges the gap between design and operational realities |

Optimizing Inflow Management | - Reduces operational losses by 5-20% through improved inflow patterns - Ensures better water regulation by maintaining allowable depth and velocity - Improves efficiency and reduces water wastage |

Implementation of Automated Control Systems | - Reduces operational losses by 15-25% - Improves water distribution and efficiency - Centralized systems optimize gate adjustments using real-time data - Decreases groundwater extraction, energy consumption, and carbon emissions |

Canal Lining with Concrete and Other Hard-surface | - Significantly reduces seepage losses - Durable with proper design - Fiber reinforcement minimizes cracks - Effective in reducing water losses - Practical for land reclamation systems |

Canal Lining with Geomembranes and Other Flexible Membranes | - Impermeable and highly effective - Resistant to punctures and environmental degradation (if buried) - Reduces erosion and sedimentation Bituminous Geomembranes: - Effective in diverse climates and extreme conditions - Minimal maintenance required |

Soil Compaction | - Reduces seepage by up to 90% (with side and bottom compaction) - Cost-effective and simple to implement |

Sealant for Canal Seepage Reduction | - Temporary yet effective seepage reduction - Reduces seepage by 69–100% for up to 3 months - Cost-effective for short-term solutions |

Covering and Enclosing Canals | - Significantly reduces evaporation losses - Prevents vegetation growth, seepage, and water pollution |

Floating Continuous Covers | - Reduces evaporation by up to 95% - Highly durable (e.g., polyethylene) and efficient for water conservation - Continuous seal prevents water loss |

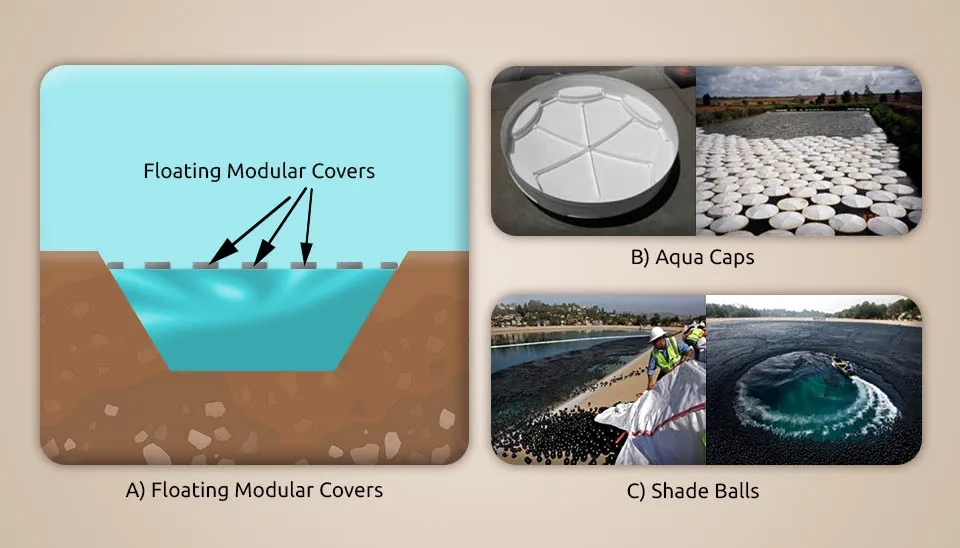

Floating Modular Covers | - Less expensive installation than continuous covers - Can adapt to water body shape due to modular design - Efficient in high-evaporation areas due to drifting ability |

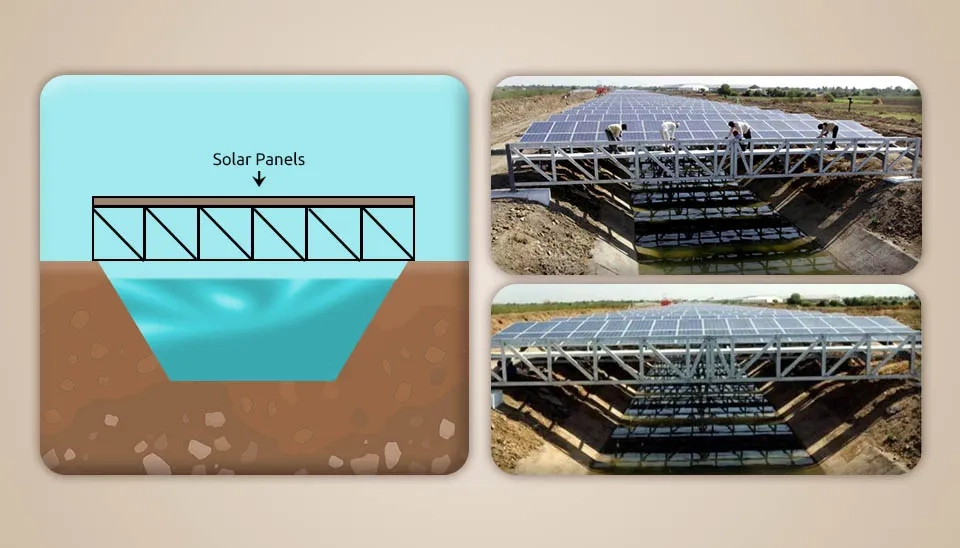

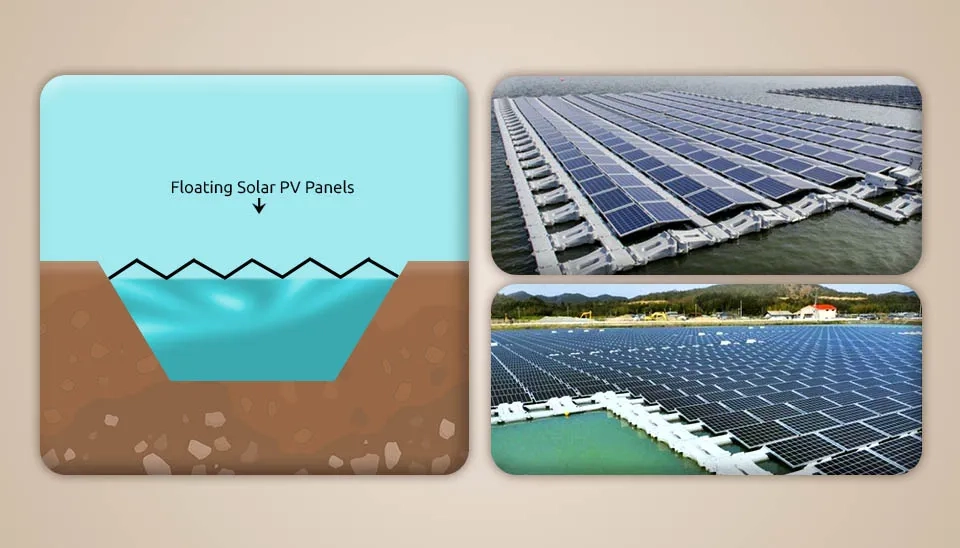

Fixed and Floating Solar Photovoltaic Panels | - Reduces evaporation by creating a cooler microclimate - Generates clean energy - Reduces aquatic weed growth - Improves photovoltaic performance by cooling the panels |

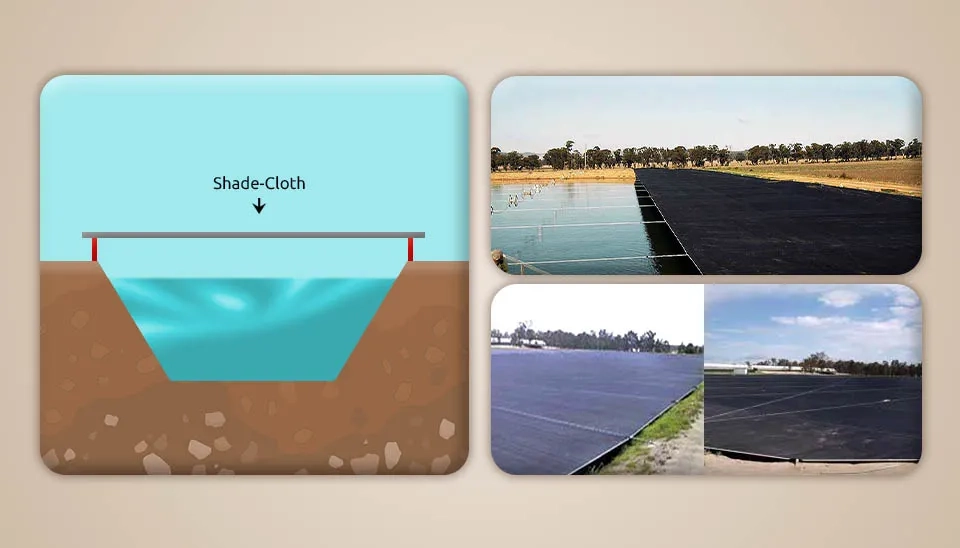

Suspended Shade Cloth Covers | - Reduces evaporation by limiting solar radiation and wind speed - Improves water quality by reducing chlorophyll-a, turbidity, and microbiological contamination - Lasts over 30 years |

Download Full Detailed Table of Solutions to Reduce Water Loss in Irrigation Canals

1. Solutions to Reduce Operational Loss in Irrigation Canals

Operational losses in irrigation canals arise from improper management and regulation of water levels and off-take structures, which may significantly exceed seepage losses. Hydraulic simulations reveal that operational losses account for up to 90% of total losses in irrigation canals, while seepage contributes only 10%. Fluctuations in canal inflow, particularly in unconventional operations, exacerbate these losses. Factors influencing operational losses, such as inflow rates and regulation methods, play a critical role in determining overall water loss (Barkhordari and Hashemy Shahdany, 2022). Addressing these inefficiencies is vital to minimize operational loss in irrigation systems, using the following solutions.

1.1. Training, Maintenance, and Performance Optimization

A practical solution to address operational losses in irrigation canals involves improving the planning and performance of irrigation distinct operation teams. Hydraulic simulations have revealed that daily water losses can range from 44% to 93%, which exceeds far from standard design guidelines. The primary factors for operational losses in irrigation canals include improper water level control, lack of regular maintenance, and poor timing in the regulation of off-take structures. Effective water level control, both upstream and downstream, and routine annual maintenance, including the calibration of off-take structures and sliding gates are crucial. Additionally, operators must ensure timely actions, such as properly timing the opening and closing of gates and maintaining stable hydraulic conditions in the main and sub-canals through precise off-take regulation. To address these challenges, investing in operator training and establishing an efficient operational performance assessment system is essential. This approach can reduce unstable hydraulic conditions and prevent unnecessary losses. Furthermore, enhancing transparency and accountability within operating companies is critical to addressing financial incentives that may discourage accurate performance evaluations. These measures collectively aim to bridge the gap between design expectations and operational realities to minimize water loss in irrigation canals (Karimi Avargani et al., 2023).

1.2. Optimizing Inflow Management

Operational losses in irrigation canals can be significantly reduced by optimizing inflow management. Hydraulic simulations indicate that these losses can decrease by 5-20% when water is introduced into the irrigation canals and distribution systems in less time and with higher inflow rates. Furthermore, maintaining the allowable water depth and velocity within the canal reaches is crucial for minimizing inefficiencies. Thesis adjustments to inflow patterns and adherence to hydraulic parameters ensure better water regulations and reduce overall operational losses effectively (Barkhordari and Hashemy Shahdany, 2022).

1.3. Implementation of Automated Control Systems

Upgrading traditional irrigation management with automated control systems can significantly reduce operational water losses, improve water distribution, and address environmental concerns. Two primary automation configurations include centralized and decentralized control systems. Decentralized controllers are practical and widely accepted due to lower implementation and maintenance requirements, while centralized systems integrate real-time data from the entire network and enable optimized gate adjustments. Implementing fully automated systems can reduce operational losses by 15%–25%, depending on the model. These savings can decrease groundwater extraction by up to 300 million cubic meters, which reduces energy consumption by approximately 450 GWh and carbon emissions by 57,500 tons annually (Hashemy Shahdany et al., 2018).

2. Solutions to Reduce Seepage Loss in Irrigation Canals

Seepage losses in irrigation canals significantly affect water conservation, agricultural productivity, and water quality, as these canals are vital for transporting water to productive farmlands. Factors affecting canal seepage include the properties of canal perimeter soils, canal perimeter treatments, canal geometry, canal flow depth and velocity as well as adjacent groundwater, canal vegetation, and the properties of canal water. Studies reveal that seepage rates vary widely between 0.1–1 m3/day per m2 of canal perimeter. Effective solutions to reduce seepage loss in irrigation canals are crucial since they can reduce seepage by 50–95%. However, improving measurement techniques, refining treatment strategies, and ensuring consistent reporting are critical to optimizing seepage control and maximizing irrigation system efficiency (Lund et al., 2023). Effective solutions to reduce seepage loss in irrigation canals are described below.

2.1. Canal Lining with Concrete and Other Hard-surface

Hard-surface liners are common and effective solutions for reducing seepage losses in irrigation canals by creating a durable barrier to limit water penetration through canal beds and sidewalls. Common materials used for these linings include concrete, cement, and natural stones like limestone, sandstone, basalt, and dolomite, which are selected based on mechanical durability and economic considerations (Ali et al., 2021). Concrete is among the most frequently used materials for canal linings, and it can help reduce seepage losses significantly but not entirely. Even in conventionally lined cement-concrete canals, seepage losses of about 15-20% have been observed due to cracks that form in the concrete over time. Adjusting the concrete’s structural properties (such as its flexural, compressive, and splitting-tensile strengths) to enhance the durability of concrete linings and minimize cracking is recommended. Using synthetic and natural fiber reinforcement is a beneficial technique that has been shown to improve the tensile properties of concrete and reduce crack formation and seepage loss (Zia and Ali, 2017). Despite the benefits of concrete and other hard-surface liners, issues related to design, construction quality, and the do foundation soil’s geotechnical properties often can lead to damage to the linings. Poor geotechnical conditions can undermine the integrity of hard-surface liners and lead to increased seepage. Addressing these factors and challenges in the design and installation of irrigation canal linings is essential for achieving lasting reductions in water loss (Rahimi and Abbasi, 2017).

Geocomposite materials are also recommended for impervious irrigation canal covers in inner-farm and on-farm systems, which reduce water losses significantly during transport. These materials ensure high reliability, durability, and practicality for land reclamation systems. While effective in minimizing seepage, geocomposite flumes face cost instability, with a 2-meter block priced at around 110 euros. However, mass production could lower costs (Kalybekova et al., 2023).

2.2. Canal Lining with Geomembranes and Other Flexible Membranes

Geomembranes and flexible membranes are increasingly employed as effective solutions for reducing seepage losses in irrigation canals, particularly in highly permeable or collapsible soils. These materials act as waterproof barriers and are typically composed of high-density polyethylene (HDPE) or other polyolefins. Geomembranes are impermeable when intact, which significantly reduces seepage losses, but they are prone to punctures during installation and use. Geomembranes can be buried under soil and concrete to prolong their lifespan, which reduces exposure to environmental degradation and stress cracking (Comer et al., 1996). The adoption of geomembranes also prevents burrowing animal damage by eliminating damp conditions on canal embarkments. Flexible membranes also address ecological and structural challenges. For instance, the polyolefin geomembrane, with its high puncture resistance, breaking strength, and flexible nature, allows for the effective lining of canal edges and corners. This material is preferred over low-density polyethylene (LDPE) due to its superior durability and suitability for canal seepage protection (Kapadia et al., 2012).

Seepage control with geomembranes mitigates erosion, sediment deposition, and groundwater level fluctuations, which enhances canal efficiency and longevity (Ding and Gao, 2020). Bituminous Geomembranes are highly effective for canal lining and addressing seepage, cracking, and stability issues in irrigation systems. With properties like impermeability, thermal stability, flexibility, and durability, bituminous geomembranes prevent water loss and withstand extreme conditions. It offers smooth water flow, minimal maintenance, and cost-efficiency, which make it superior to traditional materials like concrete. They have been successfully applied in projects across Romania, the U.S., India, Chile, and France, showing their adaptability to diverse climates and surfaces (Aguirre et al., 2023). Bituminous geomembranes offer additional benefits such as UV resistance, thermal stability, and exceptional durability. Their application effectively stops seepage and improves canal bank stability in problematic soils (Singh et al., 2023).

2.3. Soil Compaction

Soil compaction is another solution to control seepage in irrigation canals by reducing the permeability of the canal perimeter. Compaction decreases soil porosity and eliminates macroscopic preferential flow paths such as desiccation cracks, root channels, and worm tubes, thereby significantly reducing water losses. Research has shown that when both the sides and bottoms of canals are compacted, seepage losses can be reduced by as much as 90% while compacting only the sides can achieve a reduction ranging from 16% to 31 % (Burt et al., 2009). Combing compacted canal beds with clay linings decreases seepage loss compared to other lining materials such as pebbles or concrete (Yao et al., 2012). Experimental trials using impact rollers demonstrated that soil compaction can achieve a seepage reduction of 36-74%, which depends on the number of passes made during the process. For instance, the BH-1300 roller achieved a 74% reduction in seepage after eight passes (Akbar et al., 2013)

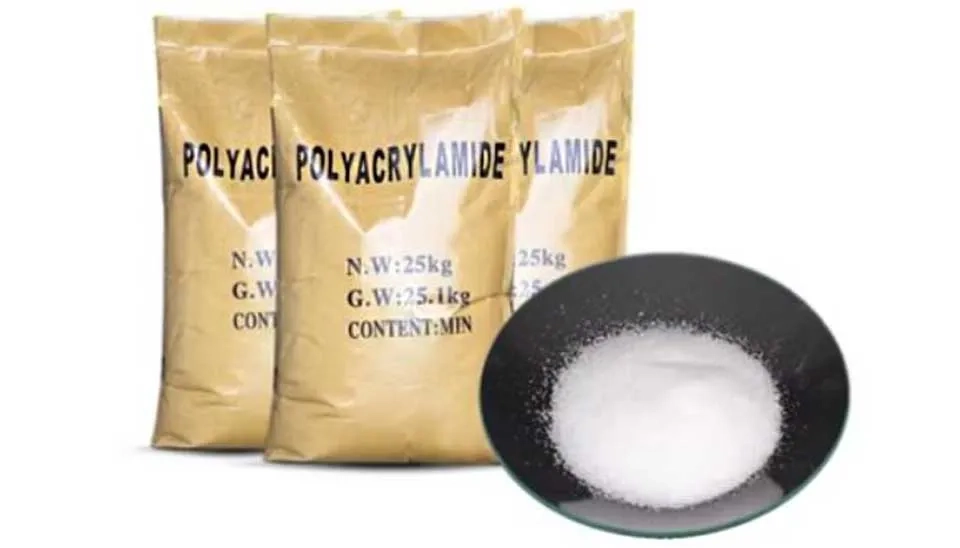

2.4. Sealant for Canal Seepage Reduction

Sealants, particularly water-soluble polymer sealants like linear anionic polyacrylamides (LAPAM) are effective in temporarily reducing canal seepage. Polymer sealants offer a cost-effective alternative to permanent liners to reduce seepage in earthen canals. Field studies demonstrate the effectiveness of LAPAM, with application rates ranging from 12.1 to 18.3 kg/ha of canal-wetted perimeter area. Seepage rates decrease by 69-100% for up to three months post-application (Lund et al., 2021). In some irrigation canal systems, seepage reduction through LAPAM can extend for multiple years. However, further studies of LAPAM and other polymer sealants are crucial to assess the impact of several factors that influence seepage control and longevity of the seal. Additionally, more studies are required to evaluate the water saving from LAPAM under various conditions, compare it with other PAM forms (such as dissolved or emulsion types), and assess the cost-effectiveness of its application (Susfalk et al., 2008).

3. Solutions to Reduce Evaporation Loss in Irrigation Canals

Evaporation loss, once considered negligible compared to seepage, has gained attention due to increasing population demands and the effects of global warming. Evaporation losses are influenced by the canal's top width, temperature, wind speed, and humidity. Among these factors, temperature plays a dominant role, especially with rising global temperatures and changing climate. Wider canals expose larger surface areas to the atmosphere, leading to increased evaporation. Evaporation from irrigation canals can be estimated using methods such as field measurements, empirical equations, and analytical approaches (Samir et al., 2023). To mitigate evaporation in irrigation canals, various solutions have been proposed, which are explained in the following:

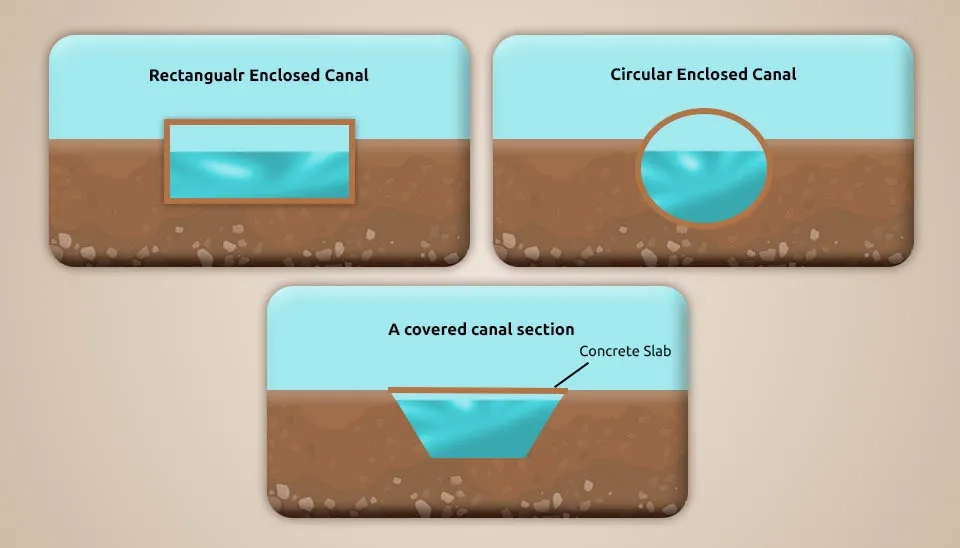

3.1. Covering and Enclosing Canals

Covering and enclosing irrigation canals can significantly reduce evaporation losses, with concrete slabs or conduit often used for this purpose. Enclosing canals prevent evaporation, vegetation growth, and seepage as well as reduce water pollution. However, challenges arise with irrigation rotation and canals of low depth and width. Moreover, covering and enclosing inhibits rainfall from directly contributing to canal flow. The irrigation rotation system indirectly minimizes evaporation by reducing water surface areas and increasing velocities as flows shift between canals to meet irrigation demands. Fully enclosing canals could address both seepage and evaporation losses but limit rainwater input, which necessitates careful consideration of the trade-offs (Abd-Elaty et al., 2021).

3.2. Floating Covers

Floating covers are innovative solutions designed to reduce evaporation and enhance water quality in irrigation canals and other surface water resources. These covers rest directly on the water's surface and form a protective barrier against solar radiation and wind. Floating covers can be broadly categorized into continuous covers and modular covers based on their structure and application, which are discussed below:

3.2.1. Floating Continuous Covers

Floating continuous covers are impermeable barriers that float on the surface of water to significantly reduce evaporation losses. These covers are typically made from materials such as polystyrene, wax, foam, and polyethylene plastic, among them polyethylene is the most durable and widely used. Floating continuous covers can save a substantial amount of water by reducing evaporation by up to 95%. Tests have shown that floating sheets like E-VapCaps are particularly effective in cutting evaporation from surface water by more than 95%. These covers prevent water from escaping by providing a continuous seal, making them highly efficient for water conservation in irrigation canals (Youssef and Khodzinskaya, 2019).

3.2.2. Floating Modular Covers

Modular floating covers consist of numerous individual units that are free to move across the surface water, unlike continuous covers. Existing designs include circular AquaCaps, Water Innovations modules, and rectangular Raftex modules. Their installation is less expensive since they do not need restraint mechanisms. The effectiveness of modular floating covers in reducing evaporation depends on how tightly the modules pack together, which typically results in slightly lower performance compared to continuous covers. Although modular floating covers do not fully cover the water surface and therefore do not achieve complete evaporation reduction, their ability to drift with wind to warmer, high-evaporation areas enhances their efficiency. This makes them particularly valuable for water bodies where evaporation hotspots concern them (Craig, 2005).

3.3. Fixed and Floating Solar Photovoltaic Panels

Using fixed and floating solar photovoltaic panels to reduce evaporation losses in irrigation canals offers an innovative and sustainable solution at the intersection of energy and water conservation. Over-canal solar photovoltaic panels have a high potential to reduce water loss by creating a cooler microclimate and reducing evaporation rates. For instance, covering California's extensive canal network with solar photovoltaic panels could save about 39 thousand cubic meters per km of canal annually. In addition to water conservation, these panels enhance photovoltaic performance by operating in cooler conditions and mitigate aquatic weed growth by reducing sunlight penetration. These systems are not only environmentally beneficial but also economically viable since the net present value of solar photovoltaic panels exceeds that of conventional land-based installations by 20–50% (McKuin et al., 2021).

Integration of solar photovoltaic panels over canals can generate a substantial amount of clean energy for grid-connected systems. These systems can contribute to the long-term sustainability of water and infrastructures in resource-scarce regions (Alhejji et al., 2021). Covering 60% of an 8 km canal with solar photovoltaic panels generates 5 MV of electricity with a commendable performance ratio of 0.78, while simultaneously reducing the evaporation of over 6000 cubic meters of water annually (Zarezadeh, 2024). These systems are suitable for rural and semi-urban areas of developing countries, where demand for affordable energy is rising (Gaikwad and Deshpande, 2017). Thus, despite the high initial installation and operation costs of solar photovoltaic panels, they are eco-friendly solutions that address the dual challenges of water conservation and energy security in diverse geographical and climatic contexts.

3.4. Suspended Shade Cloth Covers

Suspended shade cloth covers are effective solutions for reducing evaporation losses in irrigation canals, particularly where water scarcity is critical. These covers are typically made of monofilament shade cloth and are suspended above the water surface using steel cables tensioned to withstand up to 1500 kg and anchored into the canal banks with cement blocks. The cloth is available in various UV reduction ratings and can last over 30 years but requires occasional replacement depending on storm damage. Suspended shade cloth covers reduce evaporation losses without direct contact with the water by reducing solar radiation and wind speed while trapping humid air above the water. Suspended shade cloth covers, unlike plastic covers, are less prone to issues like soil accumulation or algae growth since they dry after rainfall quickly. However, their installation requires significant initial cost and advancements in manufacturing, such as wider rolls of shade cloth (Craig, 2005).

Suspended shade cloth covers also enhance irrigation canal water quality, which makes them more suitable for agricultural use, particularly in arid regions. In a drip irrigation system, suspended shade cloth covers decrease chlorophyll-a concentrations by up to 95% and turbidity from 40 NTU to less than 1 NTU by reducing solar radiation and minimizing the risk of emitter clogging in irrigation systems. Suspended shade cloth covers also create thermal gradients and reduce surface water temperature by up to 12C in summer, which stabilizes water quality (Maestre-Valero et al., 2011). Microbiological improvements include an 82% reduction in Escherichia coli and fecal coliforms. Suspended shade cloth covers are attributed to lower organic matter and reduce electrical conductivity by 8.2%, which mitigates salinity risks and enhances filtration efficiency (Maestre-Valero et al., 2013). Thus, suspended shade cloth covers reduce canal loss by evaporation and are a practical solution for improving stored water quality.

4. Conclusion

Reducing water loss in irrigation canals is vital for improving water resource efficiency, meeting agricultural demands, and addressing environmental challenges. Effective solutions to operational losses, such as enhanced operator training, regular maintenance, optimized inflow management, and the adoption of automated control systems, can significantly minimize wastage and ensure equitable water distribution. Similarly, mitigating seepage losses through methods like canal lining with concrete, geomembranes, soil compaction, and sealants can enhance the structural integrity and hydraulic efficiency of canals. Moreover, innovative solutions such as covering canals, utilizing floating covers, integrating solar photovoltaic panels, and employing shade cloths provide practical and eco-friendly approaches to reduce evaporation losses and conserve water. These solutions prevent resource depletion and offer economic and environmental benefits, including reduced reliance on groundwater, improved ecosystem health, enhanced water quality, and lower carbon emissions. By combining traditional and modern solutions tailored to specific canal systems and climatic conditions, water management authorities can achieve sustainable water distribution, reduce losses, and adapt to growing agricultural and industrial demands.