Water purification methods are upgrading to new, improved, and highly efficient systems. UltraFiltration (UF) is an innovative and competitive technology in the water treatment industry. The UF method proved that it can remove up to 99% of turbidity from water, making it an attractive process to purify water. The Ceyranbatan Ultrafiltration Water Treatment Plants Complex is a water purification plant in Baku, Azerbaijan, regarded as one of the biggest UF water treatment plants in the world with a capacity of 500,000 cubic meters of water production per day, equipped with 5280 filter modules with a capacity of 1.25 L/sec each, 13 thousand valves and equipment, 116 pumps, 6 transformers, 30 km of pipelines, 242 km of electrical and 13 km of fiber optic cables, and 3000 tons of steel structure.

So this paper is going to cover all subjects about ultrafiltration technology, its process, applications, types of UF membranes, and applications.

1. Ultrafiltration Technology

Ultrafiltration technology is a pressure-driven membrane for separating, purifying, and concentrating solutions between MicroFiltration (MF) and NanoFiltration (NF) which has been applied on small and large industrial scales. Its definition domain is to intercept the molecular weight 500~500000 Da. The corresponding pore is approximately equivalent to 0.001~0.1μm, while the operating pressures vary between 0.1~0.8MPa and the diameter of the separate components is about 0.005~10μm (Li et al., 2020).

In general, UF systems are classified as having asymmetric membranes with a porous sublayer and a thin upper layer that govern their separation performance. UF membranes have a Molecular Weight Cut-Off (MWCO) between 1000 and 1,000,000 (Nunes and Peinemann 2001).

The characteristics of UF membranes can classify them. Pore size, pore size distribution, surface size, rejection, flux, percentage of porosity, solvent resistance, temperature stability, flux decline, and pressure resistance are some of the common characteristics of ultrafiltration membranes.

2. Ultrafiltration Process

By flowing water through the UF membrane, water, inorganic materials, and Low Molecular Weight (LMW) substances are allowed to permeate the membrane. Whereas, to gain purified water, microorganisms, suspended solids, colloids, proteins, and all macromolecules are prevented from passing. UF membranes can remove pollutants from water through four mechanisms:

Physical screening

Adsorption occurs once on the surface of the membrane and in the pores

Retention in the pores

Removal of mechanical pores on the surface of the membrane

3. UF Materials

One of the key features that need to be taken into account when designing UF membranes is material selection for particles, nanomaterials, and polymers available on the market.

3.1. Polymer

Synthetic polymers, including PolyEtherSulfone (PES), PolySulFone (PSF), and PolyVinyliDene Fluoride (PVDF), are some of the common polymers used for UF. However, there has been an increase in the use of biodegradable polymers derived from a wide range of sources, including cellulose, chitin, and starch, because of the critical concerns over their impact on the environment and awareness about the lack of oil resources. Consequently, in membrane filtration, this type of polymer is widely marketed (Porcelli and Judd, 2009).

3.2. Nanoparticles

When added to the polymeric phase of an ultrafiltration (UF) system, particles and nanoparticles can make it work much better. Graphene, Clays, Carbon Nanotubes, Molecular Sievers, Metal oxide, and Zeolites are already widely recognized as effective at the removal of organic compounds when added to a polymeric membrane (Moslehyani et al., 2015).

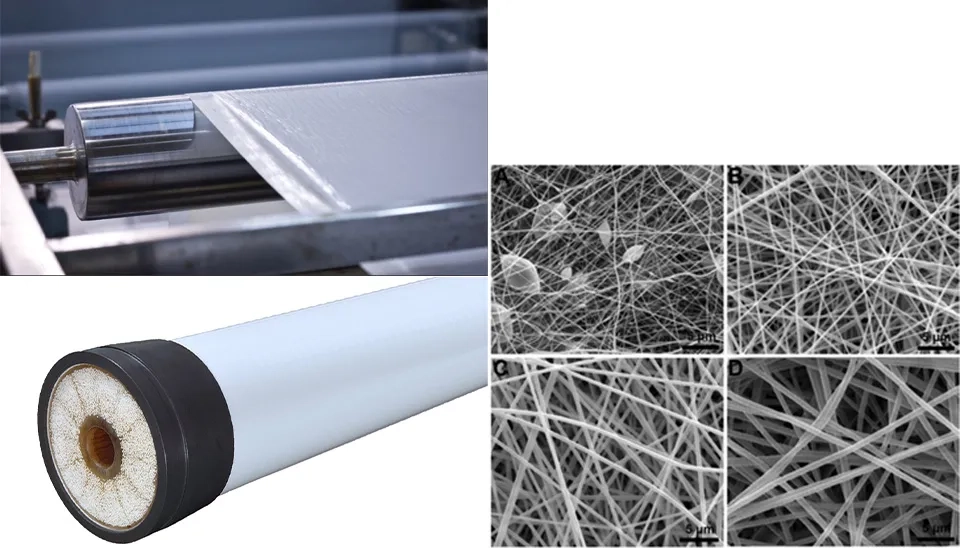

4. Types of UltraFiltration Membrane Configurations

There are different polymeric membrane shapes, such as flat sheets, hollow fibers, spiral wounds, and nanofibersheets, that have been used for submerged ultrafiltration technology. Hollow fiber membranes have always been more efficient and longer-lasting; however, flat sheet fiber membranes are easier to use (Pezeshk et al., 2011; Li et al., 2022).

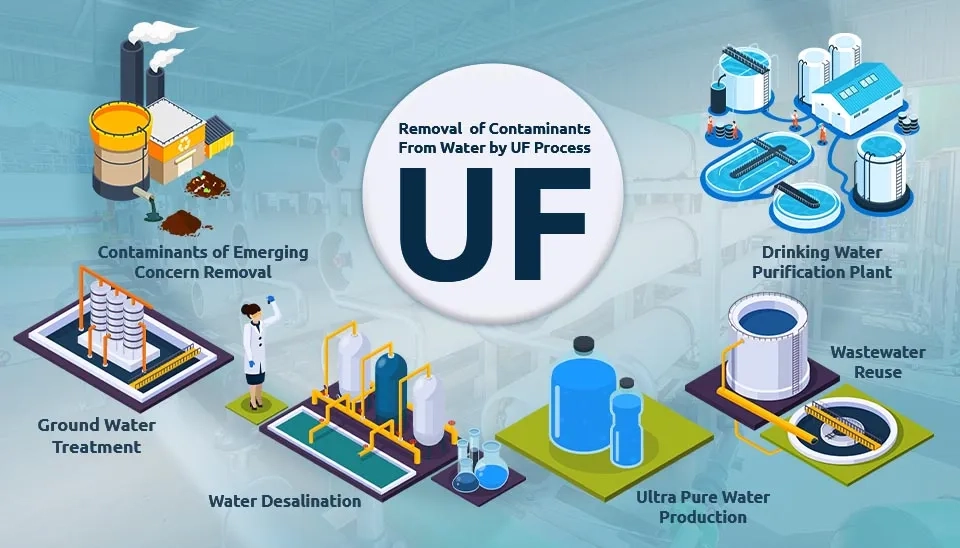

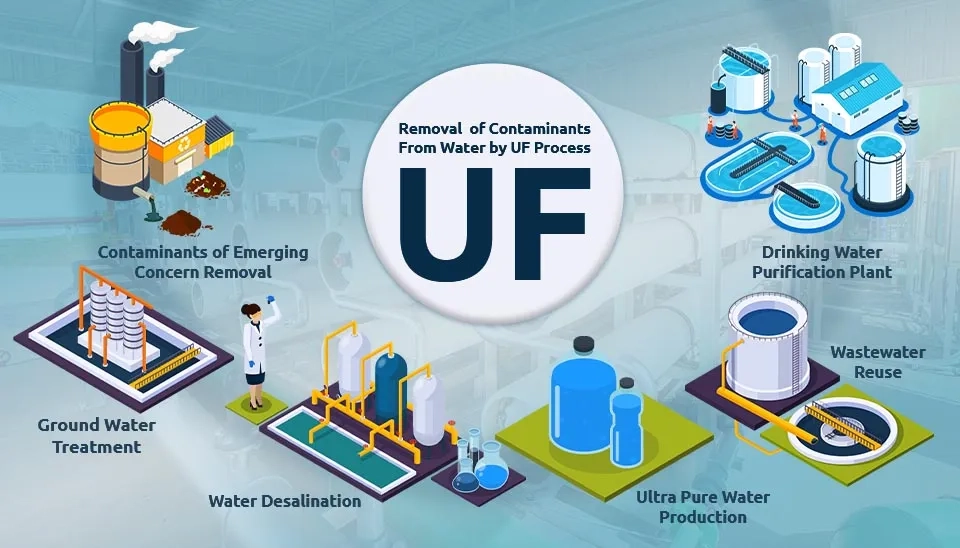

5. UltraFiltration Technology in Water and Wastewater

Ultrafiltration technology has numerous applications in different water and wastewater industries, which will be discussed below:

5.1. Drinking Water Purification Plant

After pioneering a water supply ultrafiltration water plant (2300 m3/d) in Bernay, France (AWWA, 2005), ultrafiltration technologies have been increasingly used for water treatment in cities as a key technology of 3rd generation drinking water purification. Ultrafiltration, currently the most efficient technology to ensure the microbiological safety of water, can remove almost all bacteria, viruses, pests, algae, and aquatic organisms. The use of ultrafiltration systems for municipal water works is also a matter of priority throughout the United States, Japan, and other countries. For surface waters with a relatively large amount of organic matter and to minimize the potential for membrane fouling, the coagulation-UF combination may also be taken into account.

A study by Yu et al. (2020) on the performance of UF technology in the Drinking Water Treatment Plant (DWTP) for seven years showed that by upgrading DWTP with the UF system, organic matter removal improved by 9–14%. The annual average flux of the UF membrane dropped from 28.37 to 16.51 L.m-2.h-1 During the 7-year operation and at the end of its seven-year operation, the total water treatment cost for the UF system increased from 0.032 USD. $$ m-3 to 0.050 USD.m-3 $$

5.2. Ground Water Treatment

To treat water with high turbidity and inorganic compounds like groundwater, ultrafiltration has limited capability. In this case, UF in combination with Powdered Activated Carbon (PAC) can be used for the treatment of groundwater contaminated by micropollutants such as pesticides or high organic matter content. Several water treatment plants, with a capacity from 200 to 650.000 m3/day, use the combination of Activated Carbon (AC)-UF (Laîné et al., 2000).

5.3. Water Desalination

Reverse Osmosis (RO) desalination has become a widely accepted solution to the water crisis, and increasing the use of membrane pretreatment in seawater desalination plants has become increasingly necessary over the last ten years due to advances in ultrafiltration technology for water and wastewater treatment. The rate of membrane fouling can be substantially reduced and the life expectancy of RO membranes prolonged if the RO plant is integrated with UF technology as a pretreatment. Some advantages of UF are: 1) reliable separation performance; 2) small footprint 3) reduction in chemical use 4) low energy consumption. By 2020, there were 33 desalination plants in the Kingdom of Saudi Arabia (KSA) (US-Saudi Business Council, 2021) desalinating the Red Sea and the Persian Gulf.

5.4. Ultra-Pure Water Production

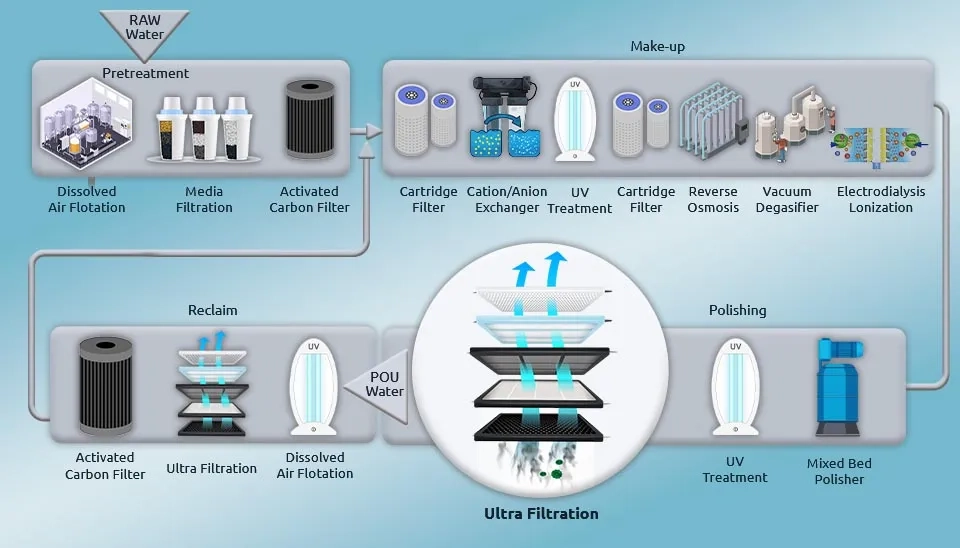

Ultra Pure Water (UPW) is artificially cleaned water with impurities removed to extremely low levels. UPW is taking part in the global water market, which has been adopted by high-value-added industries such as the semiconductor and pharmaceutical sectors, as well as boiler/cooling water for power generation (Libman, 2014). There are three stages to produce UPW: 1- pre-treatment to remove suspended solids, 2- make-up for desalination, and 3- polishing stage to elevate water quality to meet the standards of the specific industry.

Ultrafiltration technology has been applied to the final phase of UPW production systems in the 1980s in order to remove macromolecules and bacteria before being shipped to end users. In order to meet ultra-water purity demands, the combination of RO-Mixed Bed DeIonization (MBDI)-UF has established a mainstream of the UPW sector in recent decades.

Fig. 5 Placement of UF system in UPW production (Lee et al., 2016)

5.5. Wastewater Reuse

In order to create a more efficient treatment process with a high degree of automation, a stable treatment effect, and reliable effluent quality, the Ultrafiltration System, as a subsequent processing unit, has undergone various engineering practices combined with the current biochemical treatment process (Li et al., 2018). UF is suitable for both municipal and industrial wastewater treatment. For example, the treatment of animal by-products in rendering plants generates wastewater with high content of organic matter. UF methods reduced turbidity (>93%), Chemical Oxygen Demand (COD) (>84%), and Total Carbon (TC) (>31%) (Racar et al., 2016).

5.6. Contaminants of Emerging Concern Removal

While conventional water treatment plants (using coagulation, flocculation, sedimentation, and filtration) cannot completely remove Contaminants of Emerging Concerns (CECs) completely, UF has been found to be applicable in removing these kinds of pollutants. CEC removal by UF hydrophobic removal However, in the case of the removal of CECs, it is not possible to use UF alone. But, as a preliminary step prior to FO and RO or as separation steps during hybrid processes such as AC-UF, it is efficient (Heo et al., 2020).

7. Advantages and Disadvantages of UltraFiltration System

The benefits of ultrafiltration include:

The water quality of the effluents is stable and reliable; the water quality index does not change significantly, or other factors may have no effect on it.

It's efficient at removing pathogenic microorganisms.

The procedure has been simplified.

Small footprint.

There is no need for chemicals

The most important disadvantages of ultrafiltration treatment are membrane costs and fouling. The main problem encountered in the application of UF membrane technologies is the reduction of the permeation rate during the membrane process, called fouling. Inorganic fouling, particulate and colloidal fouling, organic fouling, and biofouling are various types of UF membrane fouling.

If you are interested in different types of fouling and solutions to address this problem, click here.

8. Conclusion

UF is a third-generation technology that has been extensively applied to different water and wastewater treatment plants. Ultrafiltration benefits such as low energy consumption, a small footprint, and reliability make this technology favorable for engineers and business owners. UF is mainly used as a pre-treatment of the RO system but has lately become the main method to produce drinking water. On the other hand, as membrane fouling is the main problem with UF systems, different types of materials and configurations are studied to achieve the best performance and reduce membrane fouling. Enhancing membrane materials, design criteria, operation, and maintenance leads to ultrafiltration technology being more widely used for water treatment applications.