The Trickling Filter (TF) process is a conventional treatment of wastewater that has been used for over a century. They are classified as attached-growth biological systems used in secondary wastewater treatment where wastewater is distributed over media such as plastic or rocks (Żyłka et al., 2018). TFs were first used in England in 1893 for wastewater treatment. In their primary design, TFs were placed after the primary clarifier and were filled with rock media. A secondary clarifier was also added after the TF process to remove the total suspended solids and total Biological Oxygen Demand (BOD) (Bressani-Ribeiro et al., 2018).

In this article, we will provide you with information about the biological processes of TFs and the formation of biofilm in this system. TFs consist of several important components, and we will discuss them as well. Then, we will go through different types of trickling filters based on their organic loadings. Finally, we will explain the advantages and disadvantages of the trickling filter process in wastewater treatment.

Table. Summary of Information about Trickling Filters

Types | Important Features | Limitations | Media Types |

|---|---|---|---|

Low-rate Intermediate-rate High-rate Roughing | Low Energy requirements Simple to use | Odor and fly problems Clogging | Random Plastic media Stone Structured synthetic media |

1. Explaining The Process

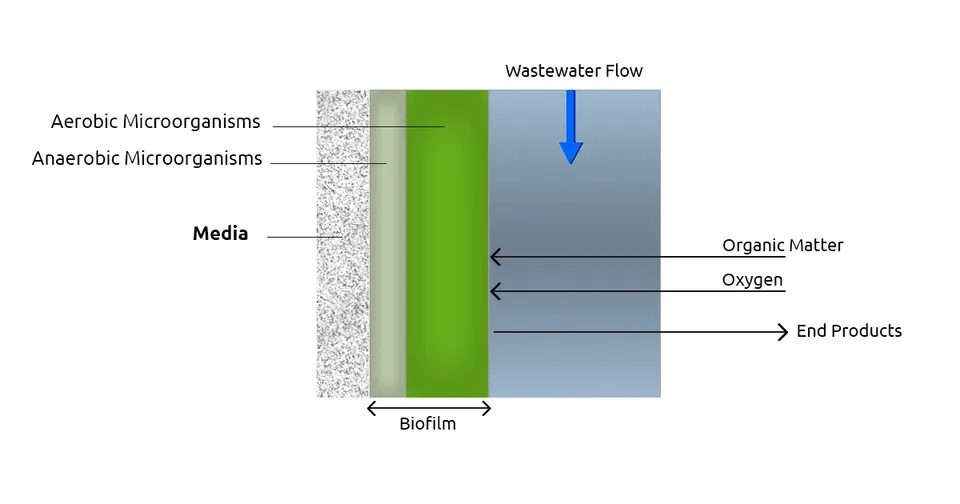

Wastewater treatment in the TF process is based on the formation of a biofilm layer attached to the surface of the support medium. The support medium consists of highly porous materials that supply a large surface area for the growth of microorganisms and form a thin biofilm layer (Gangaraju et al., 2021). The thickness of this microbial layer is approximately 0.1-0.2 mm, and it consists of aerobic heterotrophic microorganisms that can decompose BOD, Chemical Oxygen Demand (COD), and ammonia. These microorganisms break down the organic pollutants when wastewater is distributed on the support media and comes into contact with the biofilm layer as it flows down the packed bed. The microbial layer gets thicker over time as a result of the growth of microorganisms, and when the thickness reaches a certain point, oxygen can not fully diffuse into the slime layer, which leads to the formation of an anaerobic condition near the surface of the media. When the biofilm layer reaches the critical point, microorganisms near the surface of the media do not receive any organic carbon. Thus, their ability to attach to the surface is weakened, the biofilm layer gets washed off, and a new layer forms (Pilco et al., 2023; Vayenas, 2011). This process is known as sloughing. Sloughed biofilms are then eliminated in a settling tank (Oakley and Sperling, 2018). Two main mechanisms that are used for removing contaminants from biofilms are adsorption and absorption. To maintain the aerobic growth of microorganisms, oxygen is needed, and it can be provided through a natural air draft or forced aeration (Yahya et al., 2020).

2. Components of Trickling Filters

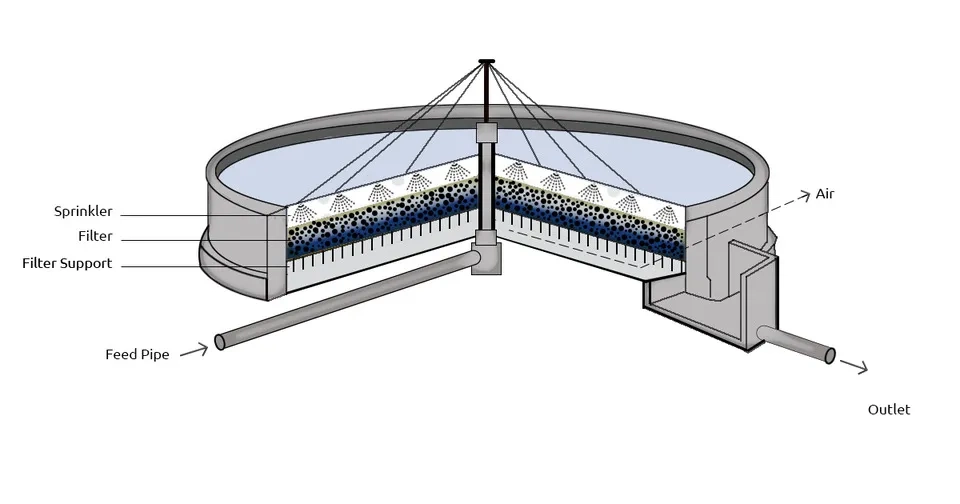

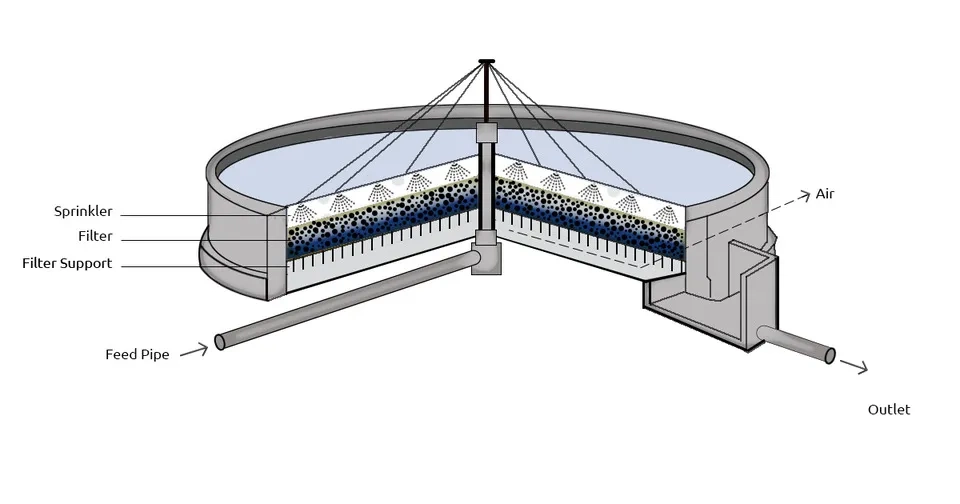

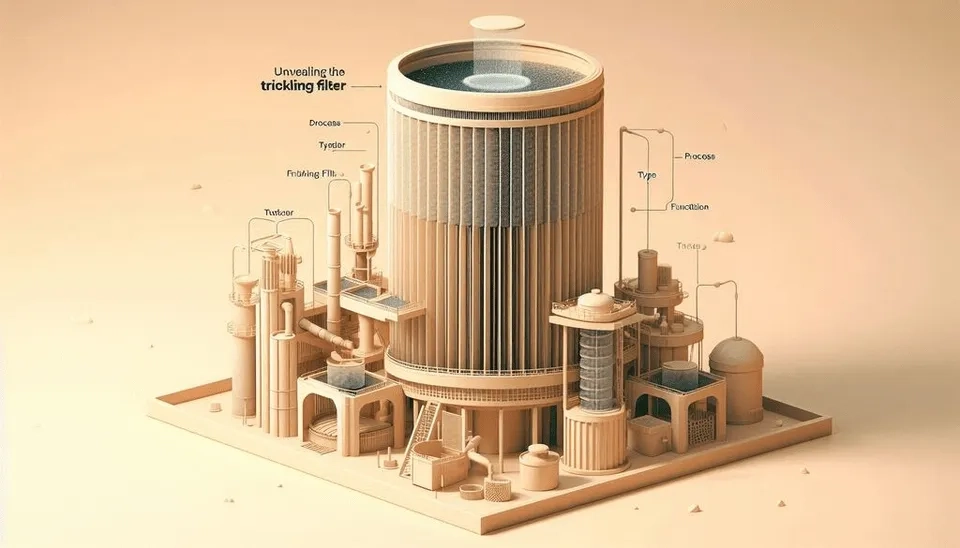

Trickling filters comprise four main parts: distribution system, underdrain system, pump station, and filter medium. Sewage enters the TF through feed pipes, and then it is sprayed on the filter medium using distributor arms. Finally, treated wastewater is collected at the bottom of the TF in the underdrain system. The following illustration shows the different parts of a TF (EPA, 2003).

2.1. Distribution System

In primary designs, spreading wastewater on the media was done via fixed nozzles. However, in modern trickling filters, rotary distributor arms are used to uniformly spray sewage on the filter. Two or four arms are used, and they are placed about 0.15 meters or more on the top of the filter. The driving force for the rotation of distributor arms can come from the hydraulic force of wastewater flow. Motor-driven distributors are used as well, in which controlling speed and flow can be done separately (Daigger and Boltz, 2011).

2.2. Filter Media

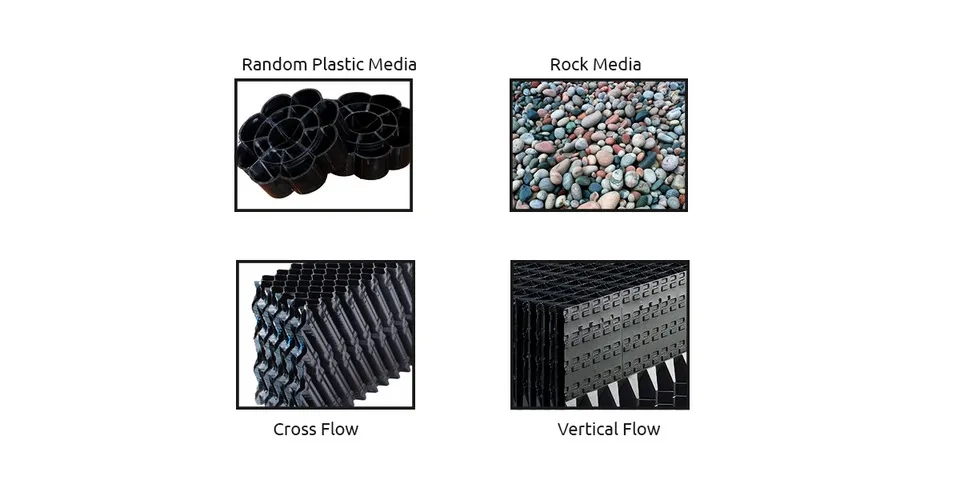

The type of media is one of the most important factors in biological fixed film methods since it provides the required surface for biofilm growth and organic degradation (Naz et al., 2014). There are a variety of media types, and the choice of media has a great effect on ventilation, microbial growth, and filter plugging (Kishimoto et al., 2015). Filter beds are typically cylindrical, and their heights range from 4 to 12 meters. However, when stone media is used, the height is llower,and it’s only 0.9-3 meters. In the case of synthetic materials, bed height can reach up to 12 meters (Hamza et al., 2016). Plastic media have a higher porosity and can be structured (i.e., vertical-flow and cross-flow) or unstructured as synthetic random pack fillings (Wik, 2003).

2.3. Underdrain System

The underdrain system serves two purposes: first, to collect the treated wastewater that trickles down the filter bed. Second, to provide air for the ventilation of the trickling filter unit. The effluent wastewater is then directed to a settling tank to remove suspended solids (Shahot et al., 2014).

2.4. Pump Station

Pump stations are responsible for transferring the primary wastewater to the distribution arms and recirculating the wastewater from the underflow. To meet the desirable hydraulic loading, the effluent wastewater is recirculated along with the influent. To avoid surcharging the secondary settling tank, it is recommended to recirculate the underflow instead of effluent from the secondary clarifier (Daigger and Boltz, 2011).

3. Types of Trickling Filters

Trickling filters can be classified into several types based on their organic loadings. The following four types of TF processes are basic categories (Jafarinejad, 2019):

Table. Four types of trickling filter processes based on their organic loads

Type | Organic Load (kg BOD/100 m3.d) |

Low-rate trickling filters | < 40 |

Intermediate-rate trickling filters | 40 - 64 |

High-rate trickling filters | 64 - 160 |

Rough trickling filters | 160 - 480 |

Low-rate trickling filters are simple and easily operated systems with high BOD removal efficiency. However, the gathering of flies due to a low hydraulic load is the main issue in these systems. Intermediate-rate TFs have a higher hydraulic and organic load, which improves the management of flies. Recirculation of effluent wastewater is needed to enhance BOD removal and nitrification in these systems. High-rate TFs are used for wastewater with a high organic loading. BOD removal efficiency is around 65-80% in these systems, which is less than low-rate filters. Because of their high hydraulic loads, fly management is not an issue anymore, and nitrification is not done enough. Roughing TFs are considered a pretreatment for high concentrations of BOD in wastewater. They can be placed before the secondary treatment of wastewater to reduce the pollution load. Nowadays, Upflow anaerobic sludge blanket (UASB) and other anaerobic processes are used instead of roughing filters for the pretreatment of highly concentrated sewage (Deng, 2018).

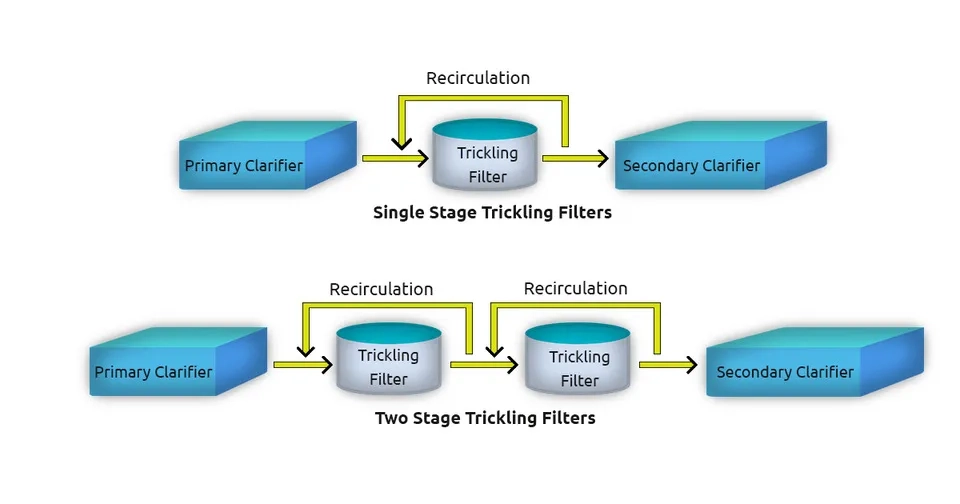

Trickling filters can also operate in a single-stage or two-stage. Two-stage treatment results in better BOD removal and nitrification. In this system, two filters are placed consecutively, and the effluent of the first filter flows into the second filter (Arous et al., 2022).

The following illustrations show the diagrams for single-stage and two-stage TFs.

4. Advantages and Disadvantages of Trickling Filters

The trickling filter process has some benefits and challenges, just like any other treatment method. The TF process requires less operational and maintenance costs compared to other biological treatments, such as the activated sludge process. By using natural aeration, the energy costs of the TF process are limited to the rotation of the distribution arms. TFs are generally simple to operate, and they have less complexity compared to activated sludge. They are also more resistant to changes in organic loads (Ali et al., 2017).

The potential nuisance of flies and odors, clogging of distribution arms, and higher head loss are some of the major issues that can occur in the TF process (Abdelfattah et al., 2020).

Table. Summary of advantages and disadvantages of the trickling filter process

Advantages | Disadvantages |

|---|---|

Lower operational and maintenance costs | Odor and fly nuisance |

Lower energy consumption | Clogging of the distribution system |

Simple operation | Head loss |

Resistant to hydraulic and organic shocks |

5. Conclusion

Trickling filters are attached-growth biological filters in which sewage is treated when it comes in contact with microbial biofilm. The biofilm grows on plastic or rock media and breaks down organic pollutants and ammonia into harmless products. TFs are typically cylindrical and contain synthetic or natural media where wastewater is sprayed on the media through a distribution system. An underdrain system is also required to collect the effluent and provide oxygen, which can be done through natural air draft or forced aeration. TFs can be classified as low-rate, intermediate-rate, high-rate, and roughing filters based on their organic and hydraulic loads. TFs can be operated in single-stage and two-stage modes. Recirculation of effluent can also improve removal efficiency and nitrification. Overall, the trickling filter process in wastewater treatment has lower energy consumption due to natural aeration. However, some challenges, such as filter clogging and possible odor problems, can occur.