Worldwide, leakage levels in water distribution systems oscillate between 10% and 55% (Ávila et al. 2021). Water transmission pipelines periodically lose an average of 20% to 30% of the water transmitted through them, and in old systems, these numbers can escalate above 50% (El-Zahab and Zayed, 2019). The mean leakage rate of networks for distributing drinking water throughout Europe is about 25% of all water provided (Scarpetta et al. 2023). According to the ISI (International Organization for Standardization) standard 11242:1994, the acceptable limit for water loss in water distribution systems is 25% of the total volume of water supplied.

Did you know that pressure-dependent leakage is a critical factor to consider in the design and cost analysis of water distribution networks? Water leakage in distribution networks results in significant financial losses, costing billions of dollars annually. In the United Kingdom alone, leak repairs are estimated to amount to billions of pounds each year. Wan et al. (2022) highlight the importance of setting goals, collecting data, preparing the gathered data, analyzing it, and evaluating the methods used for pipe leakage detection. Water distribution networks are crucial for providing clean water, but leaks can have significant impacts. Cost analysis and evaluation are essential for understanding the financial implications of leaks and prioritizing repairs. Detecting and addressing leakage is critical for maintaining a reliable and safe water supply to communities.

1. Management Of Water Distribution Networks

Recently, the management of water distribution networks has become increasingly important due to changing water availability and the need for efficient resource utilization. Distribution pipes often conceal water leaks, making them difficult to detect. The existence of leaks results in water wastage, increased pumping costs, energy inefficiency, and potential environmental and health hazards (Marchis and Milici 2019). Water utilities invest substantial resources in leak control and detection, making it crucial to understand the factors influencing pipe leakage to develop effective mitigation strategies.

2. The Costly Consequences of Water Leaks

Water leaks in distribution pipes can have far-reaching consequences. Apart from the obvious wastage of water, leaks increase pumping costs and strain the energy distribution network. They also pose environmental and health risks, especially under low-pressure conditions when contaminants can enter the system. Pipe leakages significantly impact the management of water networks and place a financial burden on water utilities. Detecting and addressing leaks promptly is essential to reduce these costs and ensure efficient water supply.

Costs for detecting leaks in a water distribution network can vary depending on factors like network size, extent of the detection system, technology used, and expertise required. Leak detection can be effective but expensive, time-consuming, and require extensive training. It's important to evaluate the cost-effectiveness and long-term benefits of reducing water losses and infrastructure damage (Marzola et al. 2021). The Environmental Protection Agency (EPA, 1992) developed standardized costs for distribution systems for water supply, which can serve as a reference for professionals in the industry. Additionally, Clark et al. (2002) and Shao et al. (2023) presented equations that can be used to estimate the cost of system construction, expansion, and rehabilitation.

3. The Relationship Between Leak Outflow and Hydraulic Parameters

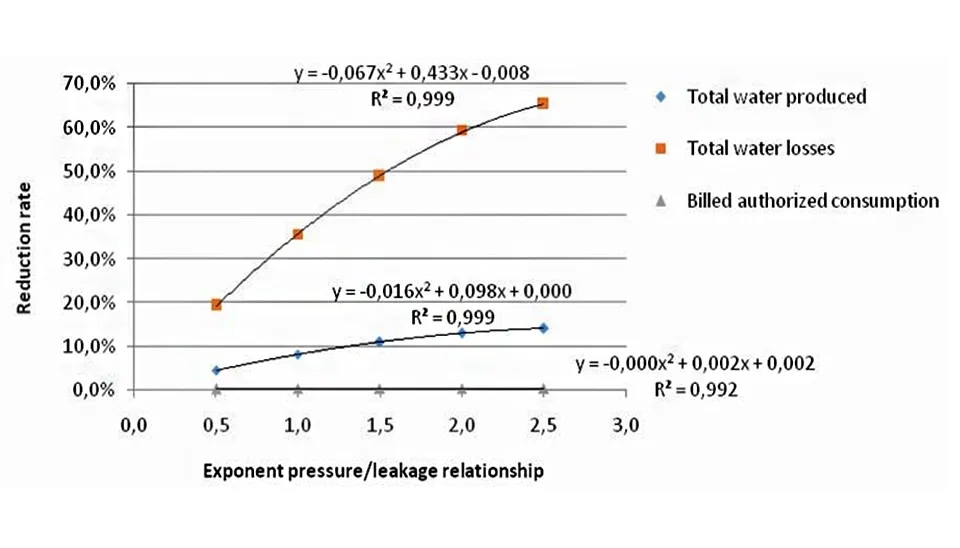

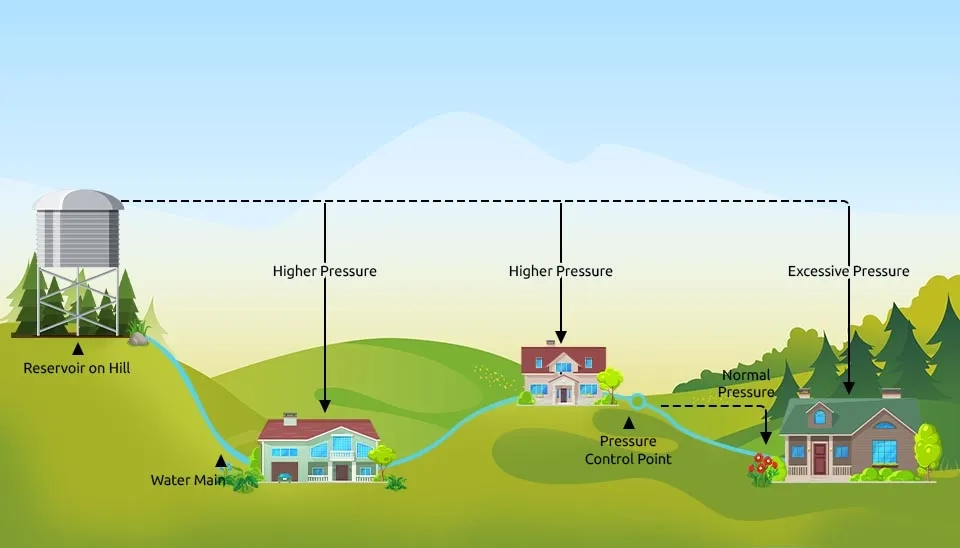

Understanding the relationship between leak outflow and hydraulic parameters is crucial for accurate leak detection and estimation. Studies have shown that the rate of water loss through leaks is influenced by the pressure modification in the distribution network. Factors such as leak area, shape, internal and external pressure, and pipe material affect the flow rate of leaks. Higher pressure leads to larger leak flow, while pressure management practices aim to reduce pipe leakage rates and the occurrence of new failures (Ambrose et al. 2008; Marchis and Milici 2019).

A recent study presented by Marzola et al. (2021) proposes a pragmatic approach for leakage detection and localization based on the hydraulic model of the water distribution network. The method involves calibrating the hydraulic model, comparing simulated pressures with observed values in the field, and applying engineering judgment and an enumerative procedure to detect and localize leakages. The study demonstrates the effectiveness of the proposed method in detecting and localizing leaks in a case-study network. In various practical scenarios, it can be difficult to determine the connection between pressure and flow rates caused by leaks in different types of pipes. This is because various pipe materials have unique relationships, and the estimation process typically relies on empirical methods or knowledge gained from practical applications (Gomes et al. 2013).

4. Leak Detection Techniques and Challenges

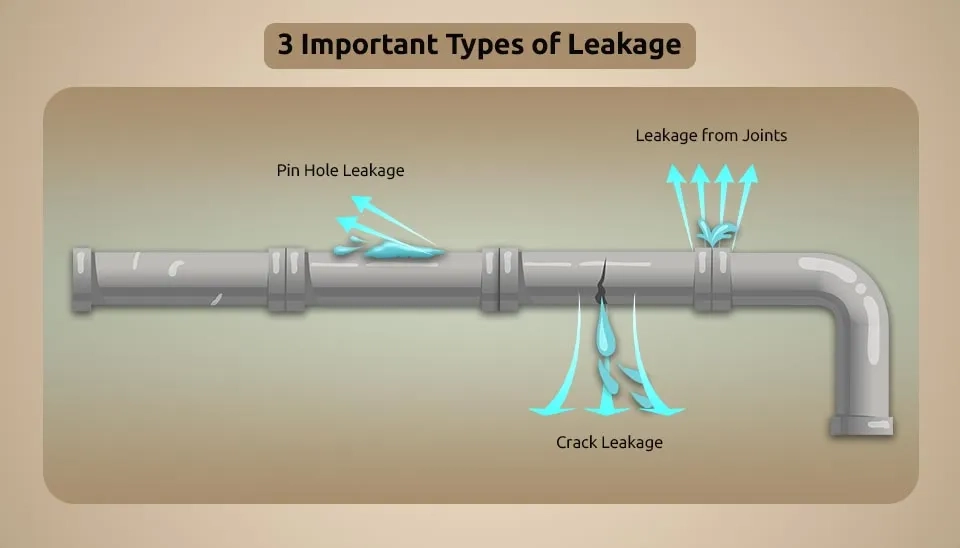

Detecting leaks in water distribution pipes is a challenging task. Various techniques have been developed to identify leaks, both in steady-state and transient conditions. However, accurately detecting leaks solely based on their dimensions proves to be unreliable. The development of leak detection techniques requires a comprehensive understanding of the relationships between leaks and hydraulic parameters, as well as the characteristics of different leak openings and pipe materials (Marchis and Milici, 2019).

Another review article provides an overview of leak detection techniques and the progress in the field (El-Zahab and Zayed, 2019). The article emphasizes the importance of addressing leakages in water transmission pipelines, which contribute to a significant portion of water loss in water distribution systems. The study highlights the costs associated with leak repairs, estimated at billions of pounds annually in the United Kingdom alone. The article also mentions the risks associated with leaks, such as the introduction of contaminants and pathogens into the network. Researchers have been dedicated to developing techniques for leak detection and location to minimize the negative impact of leaks.

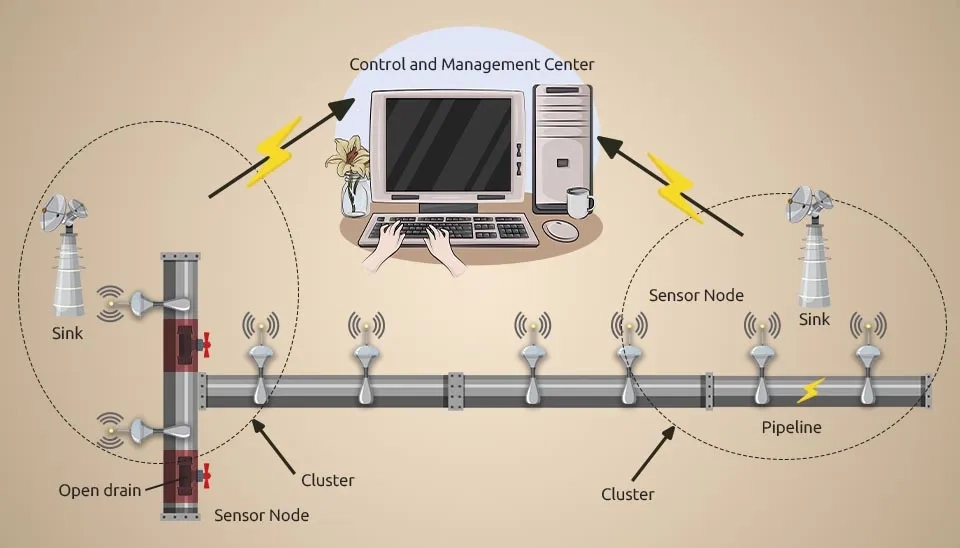

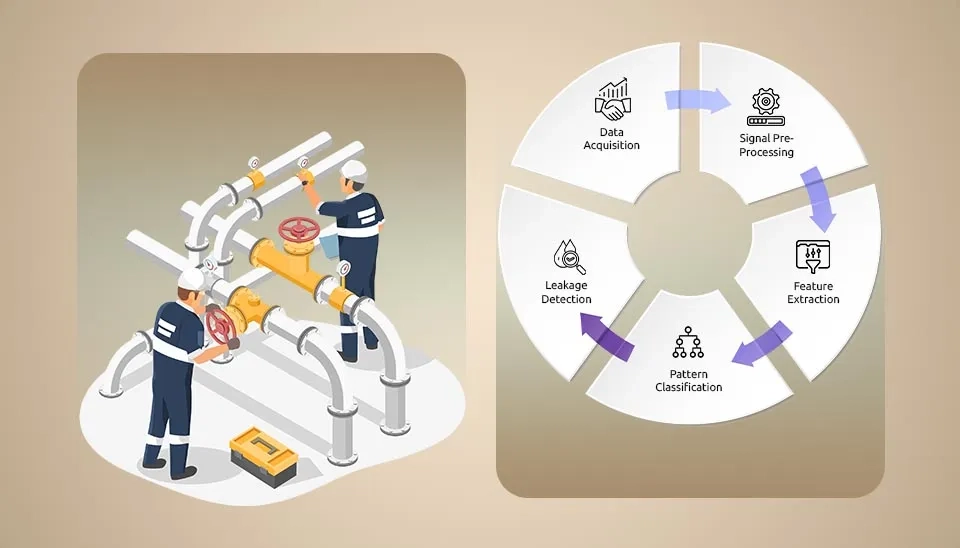

Acoustic sensors: By listening to the sound of the water escaping from the pipe, these sensors can identify the vibrations caused by leaks in pressurized pipes. Leak detection techniques can be as follows (Yazdekhasti et al. 2018; Kilinski, 2019; Korlapati et al. 2022; Yussof and Ho, 2022):

Acoustic sensors: By listening to the sound of the water escaping from the pipe, these sensors can identify the vibrations caused by leaks in pressurized pipes.

Flow measurement: The flow measurement technique detects any changes in the flow rate and pressure of water in the pipeline, which may indicate a leak.

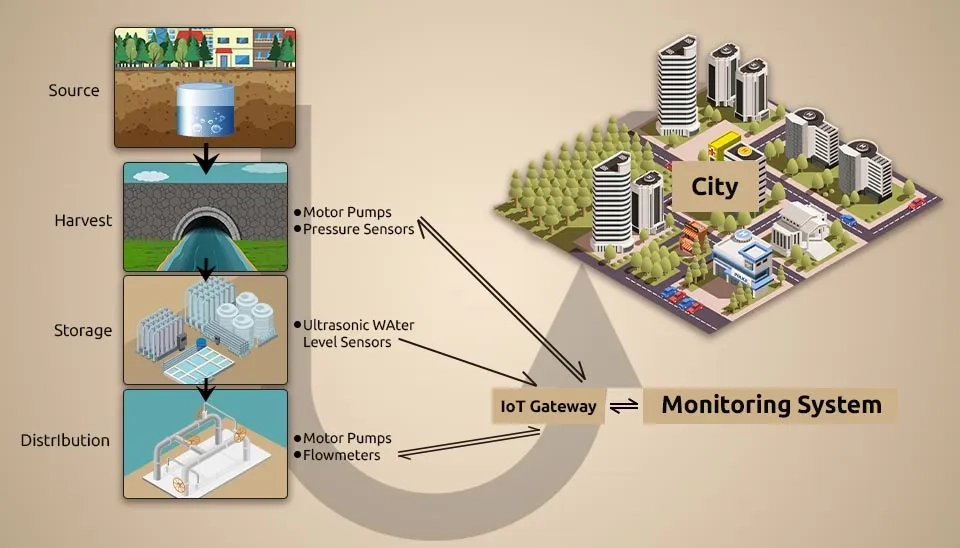

Computer vision: use smart cameras installed in remote locations and connected to the Internet of Things (IoT) to detect leaks in real-time.

Pressure sensors: These devices check the pipeline's water pressure for any alterations that might point to a leak.

Satellite imagery: This method makes use of satellite imagery to find changes in the ground's surface temperature above the pipeline, which could signify a leak.

Smart water leak detectors: These compact, often wireless devices are installed near fixtures or appliances and can instantly detect leaks using sensors. Once they identify a leak, these devices send alerts via smartphone apps and, in some models, even automatically shut off the water supply to prevent damage.

5. Estimating Leakages in Different Pipe Materials and Conditions

Leak estimation is a critical aspect of leak management. Researchers have focused on studying the behavior of different types of leak openings, such as round holes and longitudinal and transverse cracks, in pressurized pipes made of various materials like uPVC, steel, cast iron, and polyethylene (Mora-Rodríguez et al., 2014; Adedeji et al., 2017). Accurately predicting leakages requires considering both rigid and deformable pipe materials, as well as different crack geometries. Further research is necessary to improve the understanding of leakages and develop comprehensive mathematical models (Marchis and Milici, 2019). There are different methods for estimating the level of pipe leakage in a network, depending on parameters such as service pressure, orifice size, and pipe material.

Equivalent Hole Method: This method involves converting the leak opening area to an equivalent size of a circular hole and utilizing the orifice equation to determine the leak flow rate.

BABE Method: The Background Leakage and Emitter Coefficient (BABE) method is used to estimate the background leakage in a water distribution network. It involves measuring the minimum night flow (MNF) and emitter coefficient (EC) to determine the background leakage (Negharchi and Shafaghat, 2020; Ávila et al., 2021).

Torricelli Theorem: This method involves measuring the water level in a tank to estimate the flow rate through a leak (Ávila et al. 2021).

FAVAD Concept: The Flow Analysis by Visual and Auditory Detection (FAVAD) concept involves using visual and auditory cues to detect leaks in pipes (Ávila et al. 2021).

Leakage Detection Algorithm: This algorithm involves detecting and estimating background pipe leakage in water distribution networks using network parameters and initialization (Adedeji et al. 2017).

Leak Detection, Size Estimation, and Localization Algorithm: This algorithm requires flow and pressure measurements to be taken at different points in a branched pipe system to detect, estimate, and localize leaks (Anfinsen and Aamo, 2022).

6. Pressure Management for Leak Control

Pressure management plays a significant role in leak control strategies. By reducing the pressure within the distribution network, the pipe leakage rate can be effectively controlled. Implementing hydraulic models that accurately estimate leak outflow is essential for assessing the cost-effectiveness of system improvements. However, defining the relationship between leaks and functioning conditions in damaged pipes are challenging. Different pipe networks may require tailored approaches to achieve accurate leak detection and efficient pressure management (Marchis and Milici, 2019).

7. Cost-Benefit Analysis of Leakage Reduction Methods

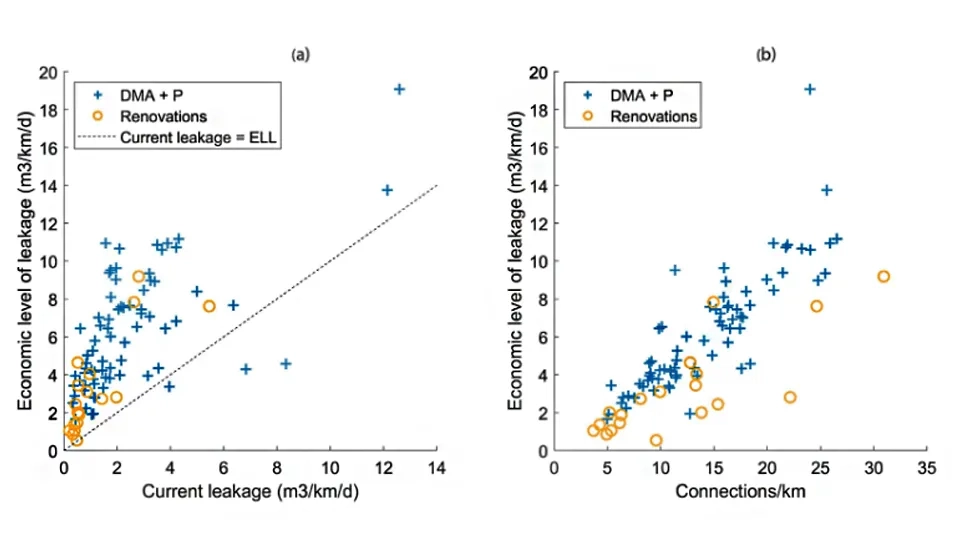

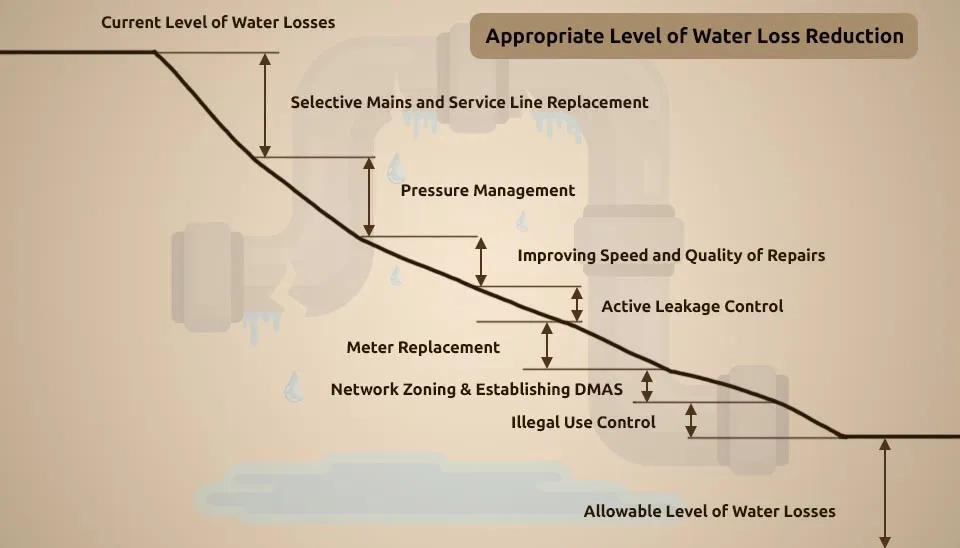

Reducing water loss from water supply systems is a vital step toward improving resource efficiency. However, the costs and impacts of leakage reduction methods must be carefully evaluated to determine the optimal target level for water loss. A comprehensive cost-benefit analysis can help assess the effectiveness of investment-based leakage reduction methods such as district metering, pressure reduction, and pipe renovations. Such analyses contribute to informed decision-making and policy development (Ahopelto and Vahala 2020).

Different types of pipes are used in water distribution systems, each with its advantages and considerations. A life cycle cost analysis conducted by the Plastics Pipe Institute compared pipe networks utilizing PVC, DI, and PE materials. Understanding the cost implications of different pipe materials can aid in decision-making for water utilities (Sitzenfrei et al. 2023).

Apart from pipe leakage, the accumulation of sediments in distribution pipes can also impact the efficiency of water systems. Ghobadian and Mohammadi (2023) discusses the spatial and cost evaluation of water distribution systems, including the modeling of water pipe deterioration. By analyzing predictors and factors associated with pipe deterioration, water utilities can proactively address sediment-related issues and minimize maintenance costs.

8. Setting Optimal Water Loss Targets

Determining the appropriate level of water loss reduction is a complex task for utilities. Leakage percentages and Infrastructure Leakage Indexes (ILIs) are often used as indicators, but they may not be suitable for all cases. Factors such as leakage levels and the costs of implementing leakage reduction methods influence the cost-benefit analysis. Setting realistic and optimal water loss targets requires considering a range of factors specific to each utility's circumstances and infrastructure (Audits, E. W. 2013; Kilinski, 2019 ; Ahopelto and Vahala, 2020).

The table shows that, for Finland, larger water utilities have better leakage performance compared to small utilities. This implies that an increase in utility size leads to a reduction in both the water leakage percentage and the Infrastructure Leakage Index (ILI). This conclusion can be interpreted as larger systems being benefited by more effective infrastructure, better maintenance practices, or economies of scale. In contrast, the smaller utilities exhibit wider variability as well as higher maximum leakage values, indicating greater scope for improvement.

Table 1. minimum and maximum values for important characteristics of pipe leakage levels for the 92 Finnish water utilities grouped by size and the share of utilities with leakage reduction potential in the size groups in 2015–2017.1 ILI: Infrastructure Leakage Index (Ahopelto and Vahala 2020).

Indicator / Utility Size | Small (n = 43), 3,000–10,000 population, 900–3,700 connections | Medium (n = 39), 10,000–60,000 population, 2,000–16,000 connections | Large (n = 10), 60,000–1,200,000 population, 11,000–73,000 connections |

Service Connections/km | 4–21 | 5–31 | 13–27 |

No. of People/km | 7–67 | 17–198 | 70–365 |

Leakage % | 4–49 | 6–28 | 6–20 |

Leakage (m³/km/day) | 0.2–7 | 0.4–5 | 1–13 |

ILI (Infrastructure Leakage Index) | 0.2–4.4 | 0.3–2.2 | 0.6–5.2 |

9. Leak Estimation for Future Research

Numerous studies have focused on leak estimation, but the field remains open for further exploration and improvement. Researchers continue to work toward finding a unifying theory for leakages, considering factors like pipe materials, geometry, and pressure conditions. Developing accurate mathematical models and simulation tools is crucial for detecting and reducing leakages. Ongoing research efforts aim to enhance the precision and efficiency of leak estimation methods and promote sustainable water management (Marchis and Milici, 2019).

10. Conclusion

Leakage in Distribution Networks presents significant challenges for water utilities. The cost analysis and evaluation of leakages play a crucial role in developing effective strategies for leak detection, control, and mitigation. Understanding the relationship between hydraulic parameters and leak outflow, as well as the cost-effectiveness of various methods for reducing pipe leakage, is essential. Ongoing research and advancements in mathematical modeling and simulation tools are vital for improving leak estimation accuracy and enhancing leak management practices.

In conclusion, detecting leakage in water distribution pipes involves cost considerations that encompass the implementation of leak detection methods, the scale of the distribution network, and the technologies employed. By utilizing advanced data analytics, hydraulic models, and a combination of data-driven and model-based methods, water utilities can improve the efficiency of leak detection, reduce water losses, and mitigate the economic and environmental impacts associated with leakages.