The market for industrial wastewater treatment is expected to reach US $16.5 billion by 2026, according to a 2019 analysis by Acumen Research and Consulting (ARC). It is a hint that understanding industrial wastewater is crucial for both economic development and environmental preservation.

Due to the industrial revolution and the world's rising urbanization, enormous amounts of wastewater are being produced on a global scale. Considering the overall water use, the industrial sector uses 22% on average. Industrial water usage is higher in industrialized countries like North America and Europe than it is in developing countries, at 50% and 4-12%, respectively. According to the UN-Water, 80% of the total wastewater produced is discharged into water channels, endangering both human health and aquatic life and causing environmental damage (UN-Water. 2021).

Industrial WasteWater (IWW) is an issue that can be solved, but the first step is to understand the phenomenon comprehensively. Therefore, this page examines industrial wastewater examples and their sources before listing dangerous contaminants and toxins, going over a short comparison of regulations, and then talking about cutting-edge strategies for handling IWW difficulties.

1. Industrial Wastewater Definition & Examples

IWW is the aqueous waste product of compounds suspended or dissolved in water. It has a wide range of definitions, sources, and examples, but is often used to describe the use of water in industrial production processes or the cleaning activities that go along with such processes (Woodard & Curran. 2007).

1.1. Industrial Wastewater Definition

Up until the middle of the 18th century, water contamination mainly affected isolated, small regions. Then followed the Industrial Revolution, the invention of the internal combustion engine, and the rapid growth of the chemical industry powered by petroleum. With the rapid expansion of numerous Industries, a vast volume of freshwater is utilized as a raw material, as a means of production (process water), and for cooling purposes. When water is exposed to an industrial process, a wide variety of raw materials, intermediate products, and wastes are introduced into the water. Industrial wastewater actually serves as an "essential by-product" of modern industry and is a major contributor to the contamination of the aquatic environment (EOLSS Publications/UNESCO. 2009).

1.2. Industrial Wastewater Examples

Today, a variety of businesses produce wastewater, and the government of each region is responsible for defining and classifying industrial wastewater examples. For instance, the Environmental Protection Agency (EPA) of the United States provides Industrial Effluent Guidelines for more than 50 sources, while in Australia, each state has its own EPA, which has set regulations for IWW. In its Water Quality Protection Note (WQPN) 51, the Department of Water of Western Australia noted that wastewater from industries can include contaminated stormwater, cooling water, process waters, and wash-down waters. It also classified the origins of IWW into 18 categories (EPA, Industrial Effluent Guidelines. 2023, WA-WQPN, 2009).

Generally, there are two alternative ways to categorize IWW. The first is based on the process that results in the generation of wastewater, and the second is based on the industry that produces the effluent. The two cited examples, which illustrate various sorts of IWW, are presented below (Wiley. 2004, Sathya et al. 2022).

The First Approach: The Process of Generating IWW

Contaminated Rainwater

Wastewater from Sanitary and Employee Facilities

Cooling Water

Wastewater from In-Plant Water Preparation

Production Wastewater* (wash and flume water, fruit water, condensates, cleaning water)

*The following flow fractions are in some branches considered part of the production of water

The Second Approach: The IWW Generation Industry

Electric Power Plants

Battery Manufacturing Industry

Nuclear Power Plants

Mines And Quarries

Petroleum Industries and Petrochemicals

Organic Chemical-Manufacturing Industries

Iron and Steel Industry

Food Industry

Dairy Industry

Oil Extractive Mills

Leather Industry

Pharmaceutical Industry

Agriculture Industry

Textile Industry

Paper and Pulp Industry

2. Industrial Wastewater Contaminants

It is challenging to identify the pollutants in industrial discharges because it depends on many variables, including the processes used by each industry and even the region of the industry. Because of the high-tech enterprises in developed nations, these pollutants differ from those in developing nations. Wastewater pollutants of each industry source are listed in the table below based on the publication of the Encyclopedia of Life Support Systems (EOLSS) and UNESCO (EOLSS Publications/UNESCO. 2009).

Sector | Pollutant |

Iron and Steel | BOD, COD, oil, metals, acids, phenols, and cyanide |

Textiles and Leather | BOD, solids, sulfates, and chromium |

Pulp and Paper | BOD, COD, solids, Chlorinated organic compounds |

Petrochemicals and Refineries | BOD, COD, mineral oils, phenols, and chromium |

Chemicals | COD, organic chemicals, heavy metals, SS, and cyanide |

Non-ferrous Metals | Fluorine and SS |

Microelectronics | COD and organic chemicals |

Mining | SS, metals, acids, and salts |

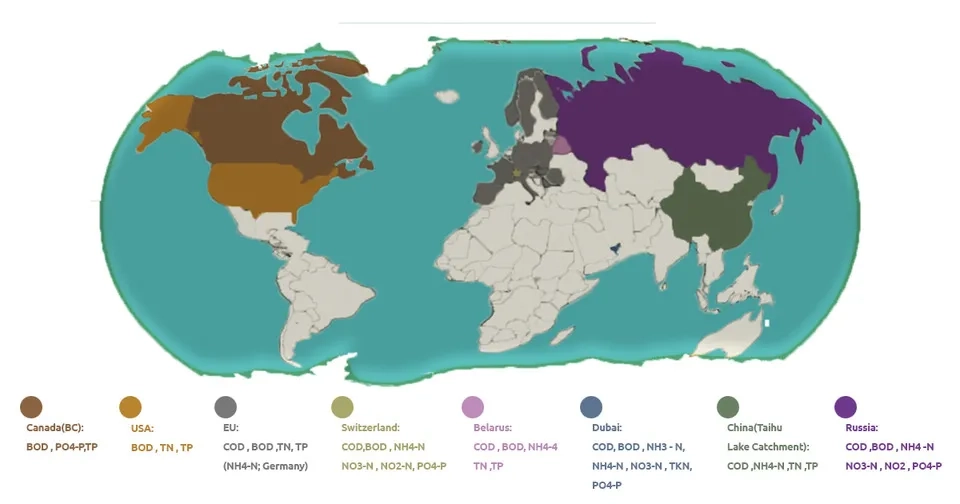

3. Industrial Wastewater Regulations

The early half of the 1970s can be seen as the start of large-scale global efforts to standardize the adverse environmental consequences. Following that, the establishment of environmental management organizations in developed countries began, and water ecosystems were added to the list of priorities. In general, the existing legislation on regulating discharges from point sources established in legal norms aims to establish the highest permitted concentrations/loads of contaminants in wastewater released into the receiver to ensure good water quality of the water body. According to the Water Framework Directive (2000/60/EC) surface water classification, "good ecological status" means a minimal deviation from the undisturbed/natural state of the water ecosystem under zero or minimal human influence, whereas "good chemical status" means the undisturbed chemical state of the waters (Preisner et al. 2020).

The pollution indicators incorporated in the legal regulations of certain locations are shown in the figure below. The comparison of these regulations revealed that, when it comes to mitigating eutrophication, the receiver-oriented policies applied, among others, in Switzerland and China, are the most sensible because they take socioeconomic aspects into account.

4. Industrial Wastewater Cutting-Edge Trends

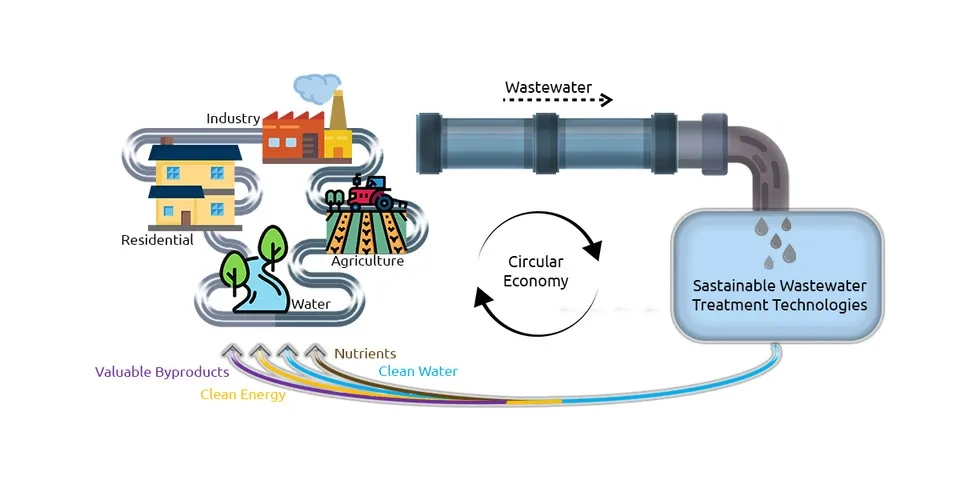

Mining secondary raw materials from industrial effluent is a great way to boost the economy, clean the environment, and meet sustainable development goals. Due to inadequate treatment options, high costs, insufficient infrastructure, lack of financial backing, and technical know-how, decision-makers find it difficult to treat industrial discharges for reuse. Most existing procedures are conventional, disadvantageous, and fail to benefit industries economically. Poorly treated or untreated industrial effluents are repeatedly deposited into water bodies, posing major health risks to humans and animals and endangering the aquatic ecosystem. Thus, industrial wastewater treatment requires efficient, cost-effective, and sustainable technology (Dutta et al. 2021).

Fortunately, there are a few cutting-edge ideas that can solve this problem. One such concept is the circular economy, which aims to maximize resource recovery from wastewater. Additionally, the partitions-release-recover approach and transforming wastewater into a bio-factory can also be convenient options. With the use of microbial technologies such as microbial fuel cells and microalgal technologies, wastewater can be treated while producing bioelectricity and valuable biomass. Nanofiltration and biochar technologies can also contribute to the efficient treatment of wastewater. These innovative ideas can significantly improve the overall treatment procedure and pave the way for a sustainable future (Malik et al. 2022; Dutta et al. 2021).

5. Conclusion

Finally, the term "industrial wastewater" refers to any watery waste that an industry produces either during the production process or at the end. Industrial wastewater is divided into various categories using various methods. Industrial effluent contaminants vary depending on the sector and stage of the production process; however, metals, Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and Total Suspended Solids (TSS) are some of the more typical pollutants. Governments devised regulations to prevent these releases from endangering water bodies, which may be more successful if they took socioeconomic considerations into account. Despite the challenges of treating industrial effluent, innovative trends are assisting us in achieving sustainable growth.

In the comments or on our social media, let us know about the main pollution indicators for industrial discharge in your area.