Due to the growing demand for freshwater all around the world, new and more advanced wastewater treatment technologies that can provide high-quality treated water, which will be suitable for domestic, industrial, and agricultural purposes should be established and used instead of old wastewater treatment technologies. It is estimated that around $38 million over 20 years will be saved by implementing the MBBR technology (Martin et al., 2009). Compact wastewater treatment plants that produce a high standard of effluent in the presence of a smaller footprint and minimize waste, have been a major concern in the world, especially in populated areas where there is limited space for the treatment plants (Barwal & Chaudhary, 2014).

In the last two decades, the Moving Bed Biofilm Reactor (MBBR) has been implemented as a compact and flexible technology for wastewater treatment. This approach is very promising in reducing pollution load and has obvious advantages over other systems. Since their design and operation have been developed, MBBRs have become an interesting and reliable alternative for wastewater treatment that can result in footprint reduction, minimal waste disposal, lower suspended solid production, and production of high-quality and reusable water (Rodgers & Zhan, 2003).

The basic purpose of this paper is to study the application and performance of MBBR technology. We also review the advantages of wastewater treatment using MBBR technology over other wastewater treatment systems.

1. MBBR Technology Performance

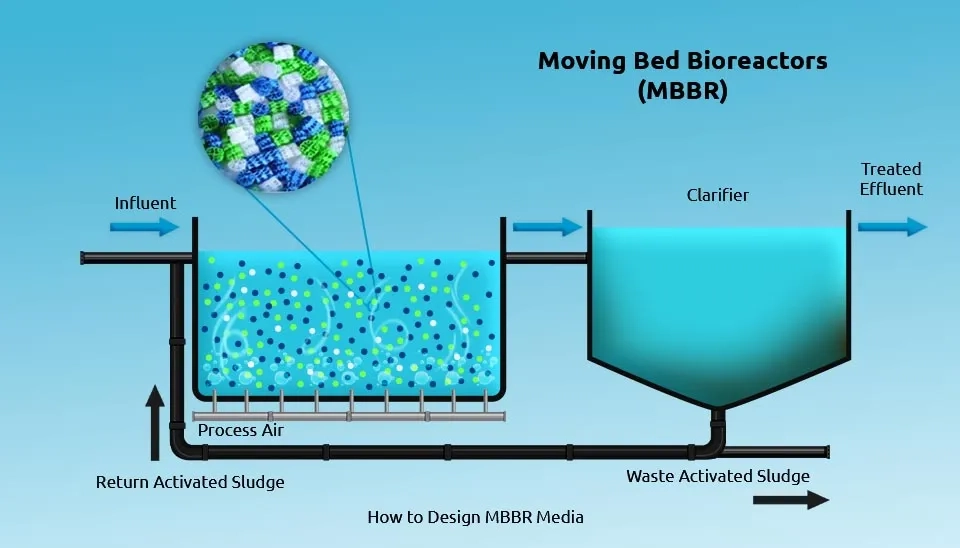

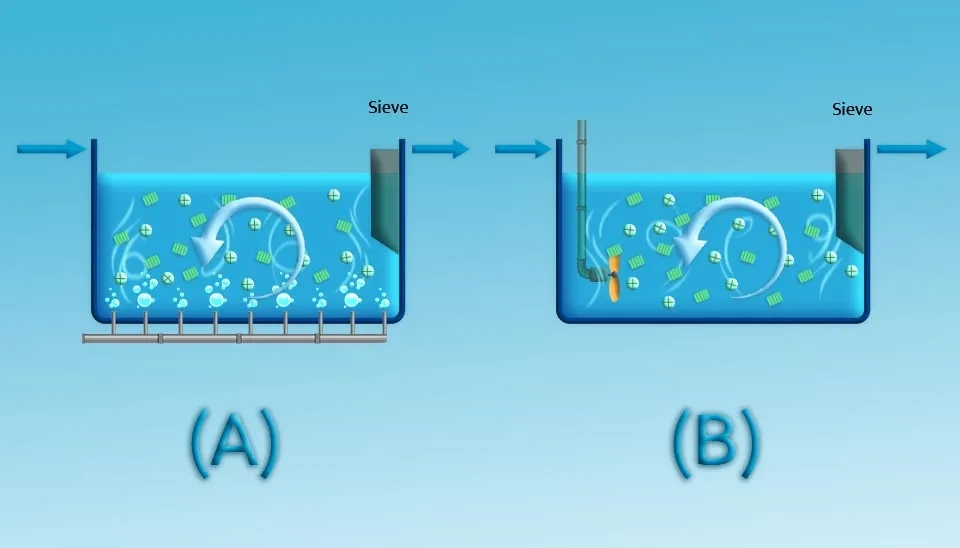

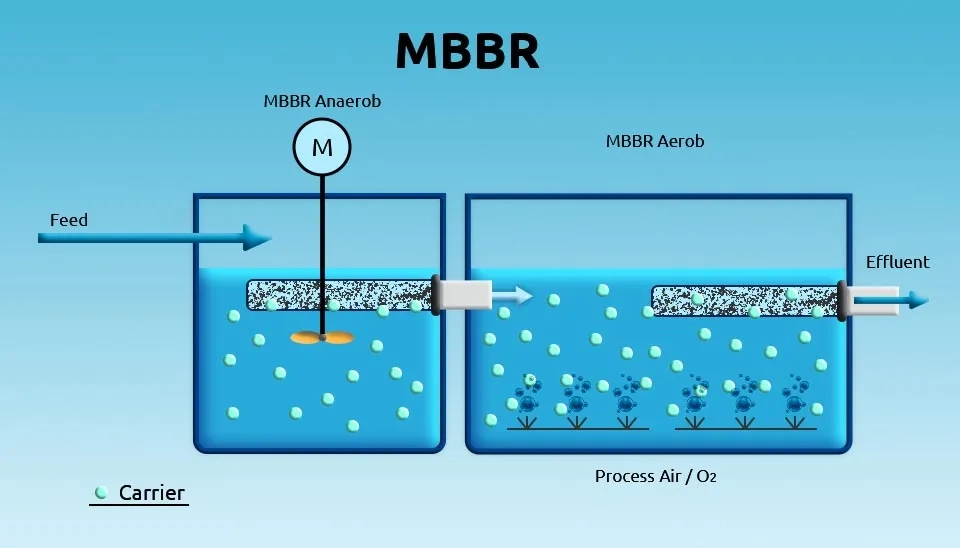

In both pilot plant studies and full-scale plants, the MBBR technology has been widely used. The reactor could be applied for aerobic, anoxic, and anaerobic processes. Due to the agitation created by the air in the aerobic process, the biofilm carrier movement occurs. However, in the anoxic and anaerobic process, a mixer (horizontal or vertical shaft) is used to keep the carrier in suspension (Rusten et al., 2006).

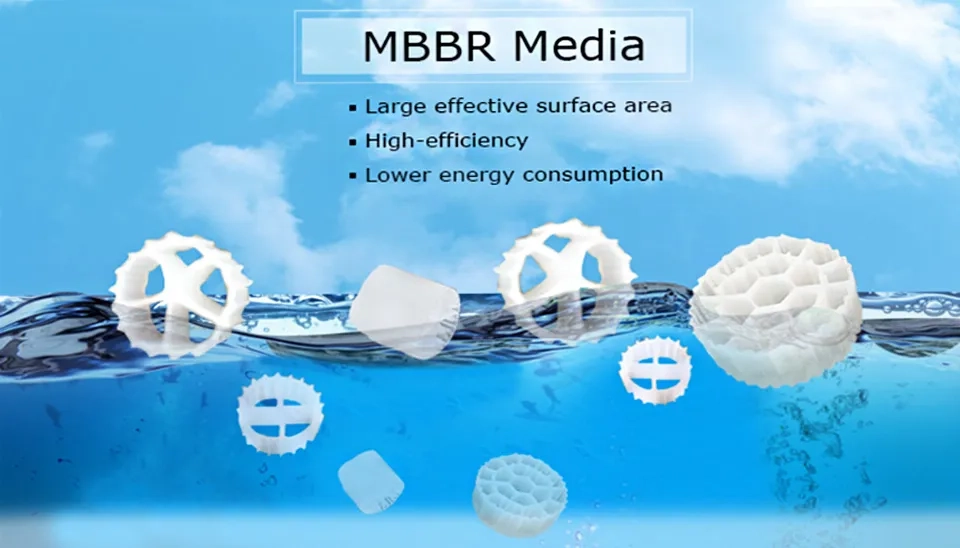

The MBBR process is carried out using a biological carrier as a media with a density close to water, so it can be kept in suspension, in which minimum mixing energy caused by aeration or mechanical mixing would be required (Henze et al., 2008). Therefore, the active biomass can grow into biofilm on the surface of these carriers when the suspended porous biofilm carriers are mixed in tanks. The MBBR system is a very effective and efficient method to retain slow-growing microorganisms like nitrifiers in the form of biofilm (Shrestha, 2013).

1.1. Biofilm and Biological Carriers

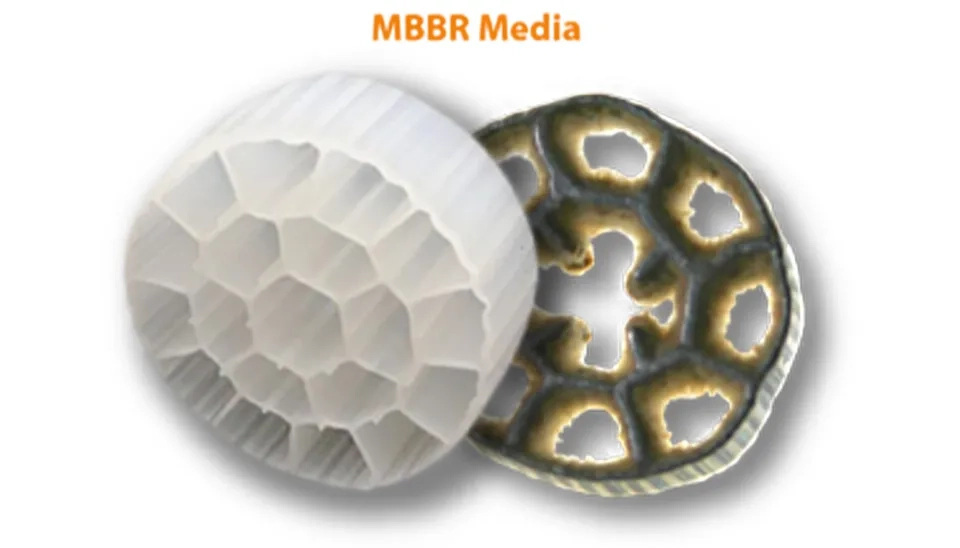

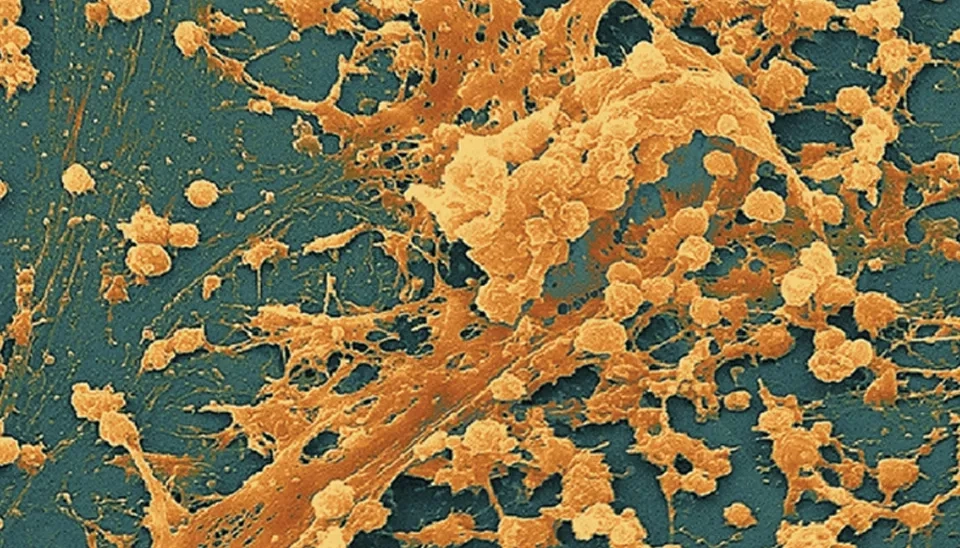

Microorganism communities that grow on the surface are called biofilms (Das & Naga, 2011). These microorganisms require a surface to adhere and grow on, and the biological carrier in the MBBR system supports their growth as a media. Biofilms that grow within the internal structures of the biocarriers can degrade dissolved pollutants in the wastewater (Briones & Raskin, 2003).

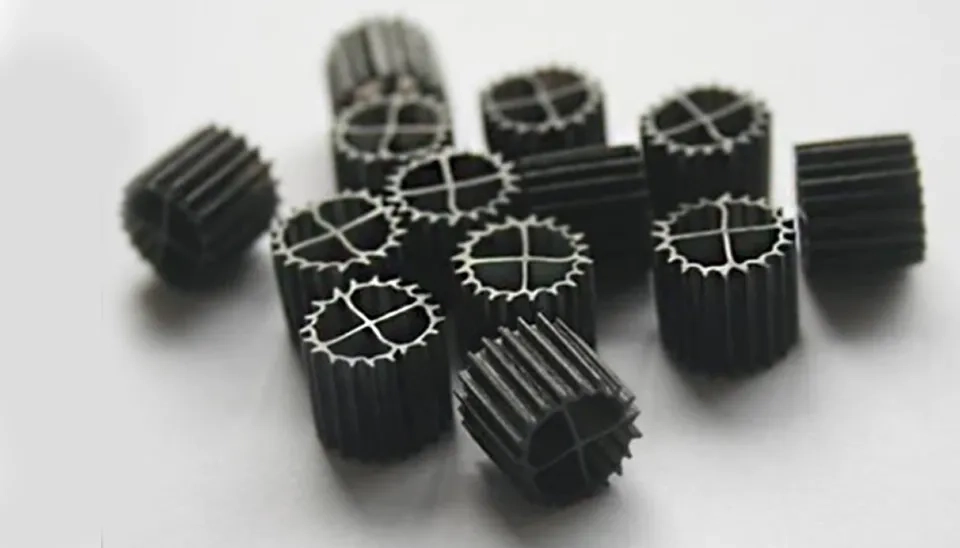

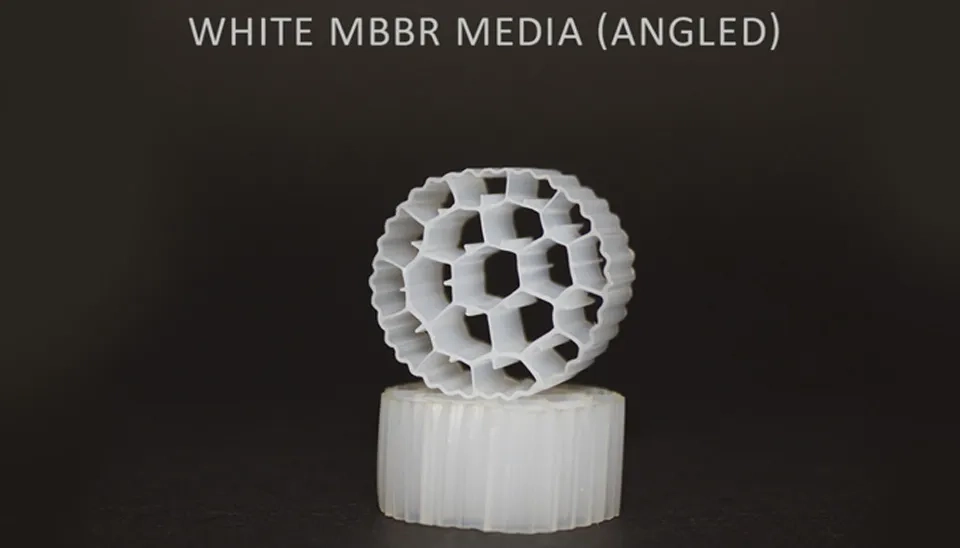

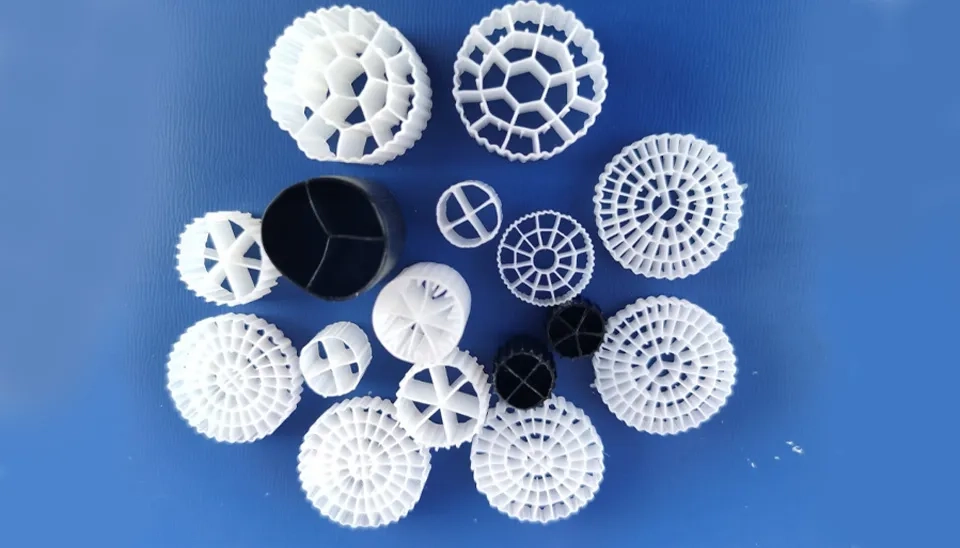

A variety of biocarrier models are now available that have different shapes and sizes with a large specific surface area to colonize the bacteria and are made up of Polypropylene (PP), High-Density PolyEthylene (HDPE), and Polyethylene (PE). There are some brands in the market for this media but the original AnoxKaldnes K1 is mainly used for effluent treatment and K3 and K5 are normally used in new treatment plants. Biofilm Chip M is another type that is mostly used for slow-growing organisms like nitrifiers and Anammox bacteria (Haandel & Lubbe, 2012). Some of the popular models in the market are Hydroxyl ActiveCell, Bio-Portz, and Siemens AGAR.

Table 1. Different models of biological carriers

Model | Company | Country | Specific surface area (m2m3) |

K1 | AnoxKaldnes | Sweden | 500 |

K3 | AnoxKaldnes | Sweden, USA | 500 |

Biofilm Chip M | AnoxKaldnes | Sweden | 500 |

FLOCOR-RMP | FLOCOR-Henderson Plastics Ltd | UK | 260 |

BioSphere | Siemens | USA | 800 |

ActiveCell 450 | Hydroxyl Systems Inc. | USA | 402 |

Bioportz™ | - | USA | 576 |

Bio-media | Fxsino | China | >550 |

Bee-Cell 2000 | - | Iran | 650 |

MB3 | - | USA | 604 |

1.2. Difference between MBBR Technology and Conventional Activated Sludge

One of the common suspended growth processes used for wastewater treatment is known to be the Conventional Activated Sludge (CAS). The CAS has been widely used in the past due to its cost-friendly characteristics. However, in recent years, overall performance has shown that the moving bed biofilm reactor has a higher rate of constituent removal efficiency compared to the conventional activated sludge in laboratory-based studies (Sidek et al., 2015).

Compared to conventional activated sludge, the MBBR technology does not require recirculation of sludge from the secondary clarifier, because the biofilm development occurs on carriers that can move freely in the reactor tank. However, it should be noted that if the system is not designed properly, some issues relating to the hydrodynamics like the formation of stagnant regions may happen. In addition, the MBBR technology has some benefits compared to the conventional activated sludge system or other fixed biofilm-based technologies. For Example, this system requires less space for its performance and implementation, it is more efficient in BOD and nutrient removal, and it is more compact (Bassin & Dezotti, 2018; McQuarrie & Boltz, 2011).

1.3. Factors Affecting the MBBR Performance

The performance of the MBBR technology depends on the percent of media provided in the reactor as well as the organic loading. The carrier filling fraction should normally vary from 60 to 70% (percentage of reactor volume occupied with carriers in an empty tank), to allow the free carrier suspension. Furthermore, mixing efficiency can be reduced when a greater proportion of filling is used (Weiss et al., 2005). Low-suspended biomass may reduce the MBBR removal efficiency since they are vital in enzymatic pyrolysis and bioflocculation in the reactor (Accinelli et al., 2012).

The biofilm area, which represents the effective carrier-specific area, is one of the important parameters in the MBBR performance and its design. In a small reactor volume, the high specific area of the carrier media allows very high biofilm concentration, which controls the system performance. The effective area of the MBBR carrier medium is reported to be 70% of the total surface area. The carrier surface properties like surface roughness and specific surface area, are one of the most important factors in the accumulation of biofilm (Bolton et al., 2006).

For efficient COD removal, the Dissolved Oxygen (DO) should be kept higher than 2 mg L-1 in a reactor. Moreover, the COD removal efficiency will be decreased when DO reduces from 2 to 1 mg L-1. With growing biofilm, DO concentration also reduces rapidly due to higher bacterial activity (Wang et al., 2006).

Proper turbulence is ideal and desirable for the efficiency of system performance. To enable the transport of substrate and oxygen to the biofilm surface, the carrier requires the development of a very thin, evenly distributed, and smooth biofilm. Therefore, thick and fluffy biofilms are not suitable for this system. Generally, it is preferable to use biofilms of less than 100 μm thickness for full substrate penetration (Leiknes & Ødegaard, 2001).

Various processes, including biofilm growth, thickness, adsorption and desorption of microorganisms to the solid surface, biofilm adhesion, and detachment to and from the solid surface or media can influence the development of biofilm. Some of the characteristics of the water medium, such as nutrient level, pH, ionic strength, and temperature, can also play a major role in the microbial attachment to the solid surface rate (Rodney, 2002).

2. MBBR Technology Application

MBBRs have been designed to comply with a broad range of effluent quality standards, including stringent nutrient limits, and this technology is applicable to a wide range of wastewater flows ranging from 10,000 to 150,000 m3 day-1. Currently, there are at least 400 large-scale wastewater treatment plants in 22 countries from all over the world that are based on this technology and it is obvious that its application in wastewater treatment has increased over the past decade (Kermani et al., 2008). Moving bed biofilm reactor technology has been successfully used for municipal and industrial wastewater treatment, including pulp and paper industry wastewater, phenolic wastewater, poultry processing wastewater, dairy wastewater, pharmaceutical wastewater, aquaculture, refinery, and slaughterhouse waste, drinking water denitrification, and also in roughing, secondary, tertiary, and sidestream applications (Borghei & Hosseini, 2004; McQuarrie & Boltz, 2011).

3. MBBR Technology Advantages

MBBR is one of the Biological treatment processes in wastewater that offers a compact treatment plant design to overcome the disadvantages of other technologies and produces higher-quality effluent in small footprints. MBBR technology has numerous advantages in the improvement of treatment facilities, which ultimately results in economic benefits by reducing the solid load of existing secondary clarifiers (Kim et al., 2011).

The MBBR process is extremely flexible and can be adapted to different sizes and shapes of a tank (Zimmerman et al., 2005). The moving bed biofilm reactor technology can also be used to upgrade trickling filters, overloaded activated sludge, and other processes. The MBBR technology operates constantly and is not influenced by clogging issues that need backwashing or maintenance work. The moving bed biofilm reactor technology has a much higher specific surface area for the biofilm than other systems (Bertino, 2010). Nitrification and denitrification may also be achieved successfully in biofilm-based processes because the nitrifiers (slow-growing microorganisms) are retained by the biofilm.

It is indicated that MBBR is very effective in removing up to 90% of chemical oxygen demand and 95% of biochemical oxygen demand with nutrients from the effluent stream at optimal conditions if there is enough retention time. Since this technology is efficient, compact, and easy to operate, it is a cost-effective way of upgrading existing wastewater treatment plants (Barwal & Chaudhary, 2014).

Consequently, the MBBR technology is approved to be an advanced wastewater treatment technology with high treatment efficiency, low capital, operational, maintenance, and replacement cost, and is a reliable and robust operation technology.

4. Conclusion

The implementation of the moving bed biofilm reactor technology in domestic sewage and industrial wastewater has increased worldwide. In comparison to conventional activated sludge, the MBBR technology offers numerous advantages such as high treatment efficiency, cost-effective implementation, and easy operation. This technology can also adapt to different sizes and spaces and is very suitable for nitrification and denitrification processes. Generally, the biofilm process indicates good efficiency for the removal of microorganisms in the wastewater. There are several biocarrier models available in the market and depending on the purpose, it is possible to select a proper type.