Water has been a manufacturing tool that industries have taken for granted for centuries due to its cheap and plentiful nature. In addition, the growing demand for water and the impact of climate change have generated an alarming water deficit all around the world (Muñoz-Alegría et al., 2021). Flotation has been a promising separation and by-product recovery technology in water and wastewater treatment that can properly remove metals, minerals, biomass, and other types of contaminants from water and wastewater (Peleka et al., 2018). In the last two decades, Dissolved Air Flotation (DAF) has been the most reliable and commonly used flotation method for removing different pollutants from wastewater, drinking water, and other industrial process streams. For clarification purposes, DAF is replacing conventional sedimentation processes (Capponi et al., 2006; Wang et al., 2009).

This article provides a review of dissolved air flotation technology, including its definition, performance, advantages and disadvantages, and application in water and wastewater treatment as well as other industries.

Table. 1. The advantages and disadvantages of dissolved air flotation system

Dissolved Air Flotation Advantages | Dissolved Air Flotation Disadvantages |

Efficient removal of OM, algae, color, FOG, microorganisms, etc. | It does not work properly in raw waters with high-density suspended solids |

Lower construction and operation costs, high loading rates | Must be protected from the weather to avoid float-freezing |

Fast startup, high separation efficiency, and longer filter runs | High energy consumption, |

Generation of thicker sludge, Low taste, and odor impact | Utilization of coagulant and flocculants |

1. DAF Definition

Since heavy metals are not biodegradable in the environment, they need to be treated with a cheap and efficient process (Matis and Mavros, 1991; Deliyanni et al., 2017). Flotation is a process of gravity separation originating from mineral processing that has been extensively applied in water and wastewater treatment (Peleka et al., 2018). Several types of flotation methods are available these days, including electrolytic flotation, ion flotation, precipitate flotation, and Dissolved Air Flotation (DAF) (Edzwald, 2007). DAF is the most utilized and effective since it can separate light and small suspended solids (Rubio et al., 2002) as well as remove different types of pollutants from water and wastewater, like colloids, ultra-fines, and fines particles, ions, precipitates, proteins, microorganisms, and emulsified oils (Rubio et al., 2002; Ross et al., 2003).

In general, dissolved air flotation separates suspended particles from water or wastewater by bringing them to the surface (Al-Shamrani et al., 2002). Moreover, the DAF process is capable of reducing some parameters such as Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and turbidity which are the main concerns in wastewater treatment (Al-Shamrani et al., 2002). The dissolved air flotation process can be considered an alternative to sedimentation in decreasing particles, turbidity, Giardia cysts, and Cryptosporidium oocysts and offers many advantages, including rapid start-up, better final water quality, a higher operation rate, and thicker sludge. In addition, unlike normal clarifiers, the DAF system requires less space and can be easily installed and set up [Burns et al., 1997; Féris and Rubio, 1999]. According to Henry’s law, in a DAF system, the process is limited to the dissolution characteristics of air into water (Bratby and Marais, 1977).

2. DAF Performance

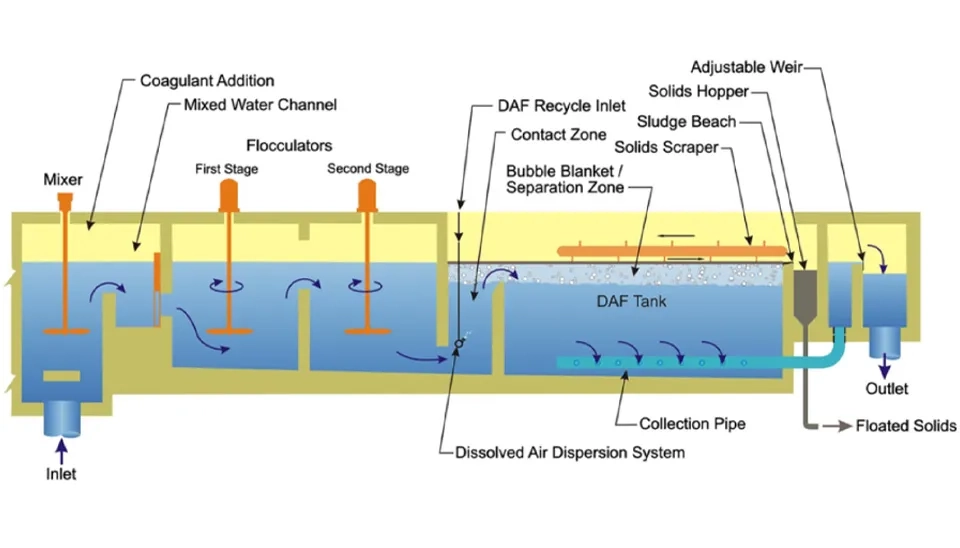

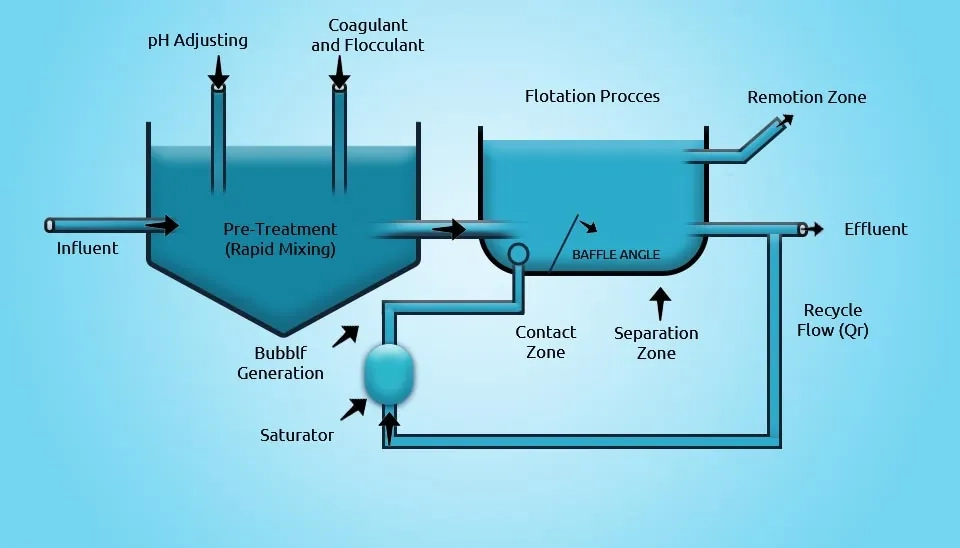

It is necessary to understand the stages of the cleaning process to determine the parameters of the DAF system. There are three main processes involved in a conventional DAF system: (1) chemical pretreatment (coagulation-flocculation), (2) micro-bubble generation, and (3) flotation. The flotation process is based on several parameters that depend on micro-bubble generation efficiency, contact between bubbles, and wastewater properties (Fanaie et al., 2019; Kouhestani et al., 2020). The coagulation-flocculation is a chemical pretreatment process that has an impact on DAF performance since it changes the properties of treated wastewater to facilitate the removal of color, turbidity, pathogenic microorganisms, etc. (Yanza-López et al., 2019). Thus, to achieve efficient wastewater treatment in different industries, it is necessary to apply chemical compounds like flocculants and coagulants (Alshahri et al., 2021).

After coagulation, most raw waters produce flocs, which are difficult to settle. Therefore, micro-bubbles adhere to the flocculated particles and form dense foam, which makes them rise to the tank surface. These flocs will eventually be removed by skimming or hydraulic flooding. Furthermore, the clarified water is drawn from the bottom of the bubble zone through a collection manifold or an opening at the end of the tank (Crossley and Valade, 2006).

3. DAF Design

There are several parameters that affect the dissolved air flotation design, according to the hydrodynamics of the flotation tank, like its geometry (Oh et al., 2019), flotation kinetics (Fanaie and Khiadani, 2020), baffle angle (Lee et al., 2020), water inflow rate (Rodrigues et al., 2019), properties of microbubbles (Kouhestani et al., 2020), wastewater density, surface tension, number of microbubbles, and microbubble rise velocity (Satpathy et al., 2020). The air-to-solid ratio (A/S), which is directly related to the required removal efficiency, is another design parameter of the DAF (Ortiz-Oliveros and Flores-Espinosa, 2020; Sanchez et al., 2018). The size and concentration of suspended solids determine the required amount of air in a DAF design. The concentration of solids that bubbles carry depends on their size (Azevedo et al., 2018).

Table. 2. DAF design parameters are classified by process (Muñoz-Alegría et al., 2021)

Chemical pretreatment | Bubble generation | Flotation process |

pH | Temperature | A/S |

Coagulation-flocculation | A/S | Microbubble size |

Zeta potential | Salinity | Microbubble rise velocity |

pH | Number of microbubbles | |

Air pressure | Flotation tank hydrodynamics | |

Flow regime | Air pressure | |

Wastewater density | Particle size and concentration | |

Surface tension | ||

Microbubble generator device characteristics |

4. Factors Affecting DAF

There are several factors that can affect the dissolved air flotation process, including the nature of the particles, size of the particles, dispersing agents, composition and nature of the influent, liquid currents, air to solids ratio, and float removal. Specific gravity is a particle or liquid characteristic to be separated. For example, sand cannot be floated, while a water-immiscible liquid (e.g., oil) or a voluminous material (e.g., activated sludge) can be easily floated. Generally, with the particle size, the floatability increases, which indicates that small particles cannot be floated properly. In some cases, by using chemical coagulants, the size of the particles can be increased. There may be some unusual concentrations of chemicals in water and wastewater that cause flotation problems or advantages. For instance, detergents (sort of a surfactant) can alter the physical properties of the sludge particle surface and generally affect the flotation process. It is also very important to determine the composition and nature of the influent. The performance of flotation will be enhanced by equalizing the influent composition and flow. Moreover, the physical design and hydraulics of the flotation unit are used to govern the liquid flow. Liquid currents must be considered when designing the tank and hydraulic loadings of the flotation unit. The amount of air and the method of mixing the air with particles should be taken into account when designing a flotation unit since a definite amount of air is necessary for flotation. Finally, for removing water carryover, a float-removal mechanism with an adequate capacity must be designed (Wang et al., 2005).

5. DAF Advantages and Disadvantages

In most cases, dissolved air flotation technology offers advantages over settling, precipitation, filtration, or adsorption. The purpose of the DAF system is to remove ions (anions and heavy metals), oils, and reusing or recycling the process waters. There are both strengths and weaknesses in the DAF process (Rodrigues and Rubio, 2007).

The advantages of dissolved air flotation include high clarifying performance on raw waters containing algae or color; low taste and odor impact; compact space requirements; insensitivity to water temperature; treating high volumes of effluent; longer filter runs; rapid start-up; better-treated water quality; a smaller footprint; operation reliability; lower construction costs; and thicker sludge generation (Feris et al., 2001; Edzwald, 2010; Capponi et al., 2006).

The disadvantages of dissolved air flotation include that the process does not work properly in raw waters with high-density suspended solids (like a turbid river). The DAF system should be protected from the weather to avoid float freezing. Using coagulants and flocculants, as well as high energy consumption, are other drawbacks of dissolved air flotation technology. Although there are no specific risks in the DAF system, general safety should be considered. At least two workers should be present in areas not protected by handrails. In addition, grease, oil, leaves, and snow should not be left on walkways or work areas, and protective guards must be in place (Wang et al., 2005; Crossley and Valade, 2006).

While the DAF system has been mostly applied in conventional water plants, there has been a growing demand in recent years for this technology as a pretreatment step in desalination reverse osmosis (RO) plants and in ultrafiltration membrane plants (Edzwald, 2010).

In general, dissolved air flotation technology is very efficient in water and wastewater treatment and has fewer operating costs compared to other technologies. It would be a perfect approach if renewable energy sources were integrated into all its processes. Due to the fact that some environments contain more complex compositions than others, it is necessary to study the trends of DAF to foresee its efficiency in the future (Muñoz-Alegría et al., 2021).

6. DAF Applications

Dissolved air flotation has proven to be an effective water and wastewater treatment process in various applications and industries, including drinking water production, oil removal, the pulp and paper industry, cosmetics, etc. (Crossley and Valade, 2006). Typical examples of the application of DAF clarifiers for water and wastewater treatment are presented in this section. The dissolved air flotation applications are classified into three main sectors: agricultural, industrial, domestic, and municipal. The efficiency of the DAF process in each of these sectors, as well as other applications, are discussed below.

6.1. Agricultural Sector

The effectiveness of DAF in treating wastewater from the dairy, slaughterhouse, and poultry industries has been carried out in several studies. The dairy wastewater contains high levels of Fats, Oil, and Grease (FOG), COD, and BOD. Releasing dairy effluents into water bodies without prior treatment would hurt the environment due to the high concentration of turbidity and TSS (Pereira et al., 2018; Leite et al., 2019). In addition, slaughterhouse waste contains high levels of nutrients, Organic Matter (OM), pathogens, FOG, detergents, heavy metals, and antibiotics. Furthermore, the poultry industry contains high levels of fats, proteins, carbohydrates, and organic and inorganic phosphates (Baker et al., 2021; Aziz et al., 2019). The DAF process is one of the most promising and primitive technologies for treating agricultural sector wastewater (Del Nery et al., 2016).

6.2. Industrial Sector

In the paper manufacturing (Ansari et al., 2018), mining (Azevedo et al., 2018), and metalworking industries (Mofrad et al., 2020), desalination (Shutova et al., 2016), oil recovery, and grease and oil removal (Aliff Radzuan et al., 2016; Rocha e Silva et al., 2018), DAF has been used in industrial wastewater treatment. Heavy metals, OM, and radioactive waste are other important parameters that should be removed from industrial waste. The dissolved air flotation technology has proven to be very efficient in the removal of heavy metals and other chemical substances from wastewater from the metallurgical (Amin et al., 2017) and mining industries (Rodrigues and Rubio, 2007). In some cases, it is difficult to remove ultra-fine metallic particles in the cleaning process which makes it essential to use different types of coagulants and flocculants that facilitate the attachment of the bubbles to the particles (Mofrad et al., 2020). In one study, to remove heavy metals (zinc chloride, cadmium chloride, lead nitrate, etc.) from the wastewater by using DAF technology, different polymers (chitosan, polyethylene glycol, and polyvinyl alcohol) were used as collectors (Al-Zoubi et al., 2015). In addition, under specific coagulation conditions, DAF is capable of removing more than 98% of the OM that exists in saline and fresh wastewater (Alshahri et al., 2021) and in desalination pretreatment systems (Shutova et al., 2016). It is reported that the DAF process can remove 20-61% of the humic substances and 38-84% of the biopolymers.

If you want to learn more about “types of coagulants”, click here.

6.3. Domestic and Municipal Sector

The dissolved air flotation application in combination with other methods has been proved to be effective in different types of domestic and municipal wastewater treatment (Zhang et al., 2014; Villar-Navarro et al., 2018; Ding et al., 2015). Domestic and municipal wastewater contains nitrogen, organic carbon, OM, FOG (Wallace et al., 2017), phosphorus, biodegradable particles, and microorganisms that can be highly infectious (de Oliveira and Daniel, 2021). It is proved that DAF by using coagulants can remove cryptosporidium and can remove Giardia cysts from effluents which provide low protozoa concentration and turbidity (Andreoli and Sabogal-Paz, 2019). Due to Choi et al. (2020), the DAF-coagulation process is a very efficient method to decrease Antibiotic Resistance Genes (ARG) from wastewater with the utilization of three types of coagulants: FeCl3, PACl, and alum. The results indicated that this combined process can effectively remove COD, TSS, and ARG.

6.4. Other Applications

Most studies on the DAF process have been focused on oily wastewater or wastewater contaminated with radioactive substances (Bensadok et al., 2007; Xiao-bing et al., 2007; Stoica et al., 1195). A significant change in pH, salinity, and temperature of oily waters by using some chemical reagents was observed during oil removal with DAF (Ghasemi Naghdi and Schenk, 2016).

DAF application has also been carried out in white waters in the paper-making industry as well as wastewater contaminated with protein (Miranda et al., 2008; Schneider et al., 1995). The application of DAF has been proven to be successful in different types of wastewater by controlling certain operational parameters. According to Offringa (1995), suspended solids of 200 to 300 mg/l were reduced to 10 mg/l in wastewater by using DAF.

In addition in Pharmaceutical wastewater treatment, cosmetics wastewater samples were successfully treated, and 11.1% and 77.7% of COD removal from wastewater was observed by using DAF and aluminum-based coagulants (Muñoz-Alegría et al., 2021).

7. Conclusion

Dissolved air flotation has potential in the treatment of wastewater from agricultural, industrial, domestic, and municipal sectors, as well as other applications. DAF has been developed in recent years and is highly efficient in combination with other cleaning methods (like coagulation). It is a recommendable technique for improving the removal efficiency of water and wastewater contaminants (turbidity, COD, BOD, TSS, oil and grease, etc.) and optimizing plant operating and energy costs. The advantages and disadvantages of DAF in wastewater treatment were also identified here. Future work should focus on developing DAF technologies that minimize the drawbacks of current processes, use renewable and clean energy, and are cost-effective, which ultimately results in sustainable development.