UltraPure Water (UPW) is described as an artificially cleaned water that a high level of contaminants are removed from it. UPW production has been widely used in the world water market and is highly adopted by a variety of industries, such as the pharmaceutical industry, semiconductor manufacturing, electronics industry, and boiler/cooling water for power engineering operations (Singh, 2009). Global Water Intelligence (GWI) has reported that in 2011, ultrapure water occupied 20% of the water market worldwide, which is expected to rise by more than $4000 million in 2025 (Global Water Market, 2014).

In an ideal condition, the UPW does not contain any sort of contaminants like suspended solids, pathogens, inorganic and organic substances, and radioactive contaminants. The main purpose of ultrapure water production is to dramatically remove all compounds except water molecules, which is practically unachievable. Therefore, the purity level of ultrapure water can be determined by industries’ demand for UPW (Choi and Chung, 2019; Lee et al., 2016).

Ultrapure water production can be achieved using a variety of technologies and different water sources depending on the purpose. These technologies are reviewed in this paper.

Table 1. Different technologies used in UltraPure Water (UPW) production

Technology | Stage of UPW production | Pollutant removal |

Reverse Osmosis | Make-up and desalination Polishing | Organic compounds, TOC, Dissolved macro molecular inorganic and organic pollutants |

Granular Activated Carbon | Desalination Pretreatment | Macromolecular organic compounds, Suspended solids, Ions |

Ion Exchange | Make-up and desalination | Dissolved macro molecular inorganic pollutants, Ions, Organic matters |

UV Irradiation | Water disinfection Pretreatment Polishing | Bacteria, Microorganisms, TOC, Isopropanol, Methanol, Pathogens, Dissolved macro molecular organic and inorganic pollutants |

TOC: Total Organic Carbon

1. Ultrapure Water Definition

With the growth in population, the demand for safe water in different applications like industry, agriculture, and domestic use has increased. The purity level of water is a determining factor for each application. Different sources of water, such as seawater, underground water, and wastewater contain different percentages of salts or impurities and can be classified due to the amount of mixed salts. Ultrapure water is completely degassed and contains any kind of salt, metal, and lime (Jande et al., 2013).

Table 2. Ultrapure water quality parameters (Bennett, 2009)

Pure water type | Resistivity Megohm. cm at 25°C | Maximum Micro Organisms CFU/ml | Maximum TDS mg/l | Reactive Silica μg/l as SiO2 | TOC mg/l as C |

Ultrapure | 18 | 1 | 0.005 | 2 | 0.05 |

TDS: Total Dissolved Solids

2. Ultrapure Water Production Process

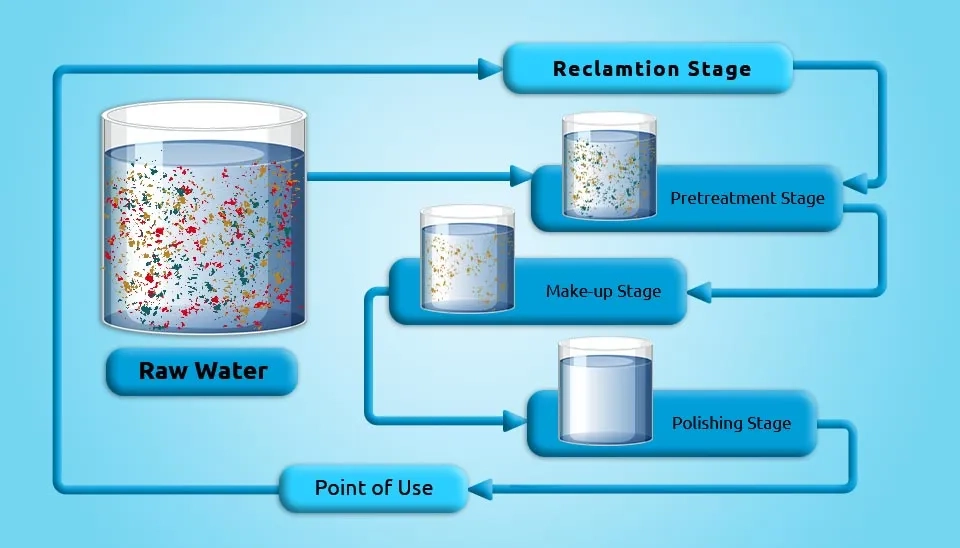

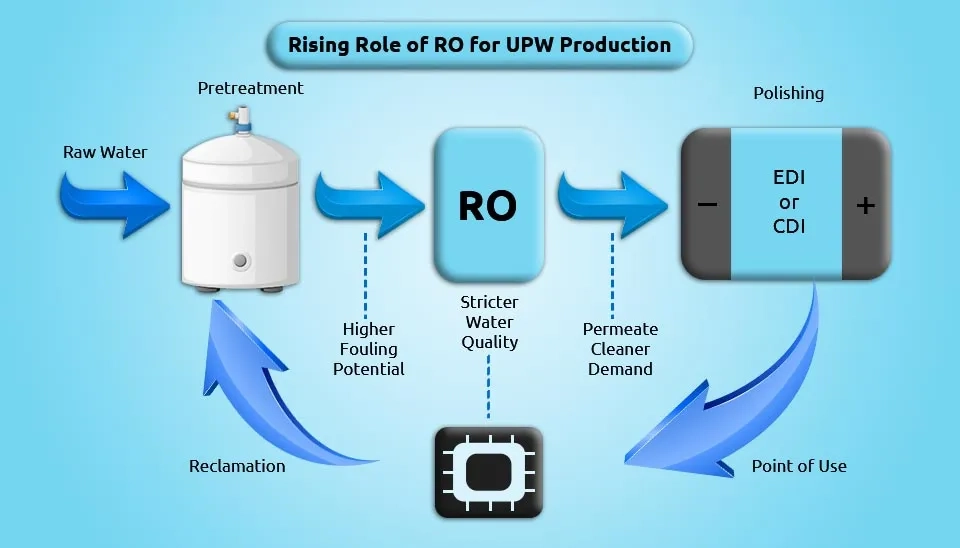

Ultrapure water production is a complex process that requires a variety of purification technologies. Conventional UPW production systems involve three main stages: (1) pretreatment for suspended solids’ removal; (2) make-up stage for desalting; (3) polishing for enhancing the water quality to reach the purposes of production lines. Moreover, the current ultrapure water production systems consist of four main parts due to the recent drift toward adopting a reclamation stage. It should be noted that the output of each stage affects the consequent process, which makes the entire production system cumulative (Libman, 2008).

3. Ultrapure Water Applications

The final purpose of ultrapure water production is to remove all compounds except the water molecules which is almost impossible in practice. Thus, depending on the specific demands, the purity grade varies.

The tap water can almost meet all the liquid cooling requirements in various industries, but numerous applications including laboratory instrumentation, pharmaceutical, laser cutting, food processing, cosmetics, plating, semiconductor industry, and other chemical processing need Deionized (DI) water. DI water is a very suitable water type for cooling sensitive electronics, due to its electrical and chemical characteristics. Moreover, deionized water is highly reactive and materials of the storage vessels and distribution piping can be easily leached out. However, since it does not contain beneficial minerals for human health and does not taste good, using it as potable water is not recommended (WHO, 2005).

Bacteria and endogenous pyrogen’s elimination is the most important priority since the UPW is often used for water injection in pharmaceutical industries (Cohen and Sackstein, 2015). The semiconductor manufacturing has also the highest demand for ultrapure water, because of the sensitivity of its precision types instruments. For this application, an extremely low level of pollutants and at least 18 MΩ cm (at 25 ℃) of electrical resistivity is needed (ASTM international, 2013; Dey and Thomas, 2003).

4. Ultrapure Water Production Challenges

Due to the development of a variety of technologies, the demand for ultrapure water in different industries has increased, which results in a huge increase in raw water consumption. In addition, it is a very difficult task to remove all pollutants from the water and it requires the implementation of different methods. In the following, we review these challenges and introduce some approaches to properly manage them.

4.1. Water Resource

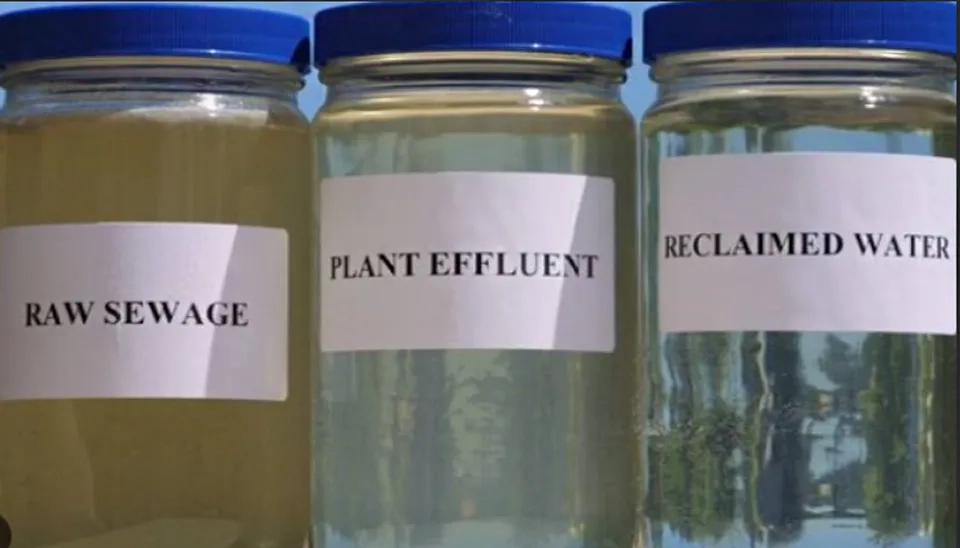

In ultrapure water production, one of the main issues is the large quantities of raw water needed to begin the process, which dramatically needs to be solved. Besides, water shortage has become a serious problem worldwide due to rapid urbanization and population growth. Thus, extensive efforts have been made by humanity to use and promote other water resources by using methods like reclaimed water utilization, rainwater utilization, seawater desalination, etc. In particular, reclaimed water and municipal waste are easily available in large quantities and they are restricted by geographical environment. Using these kinds of water resources will alter the raw water resources needed for the UPW production process (Charfi et al., 2017; Guo et al., 2014).

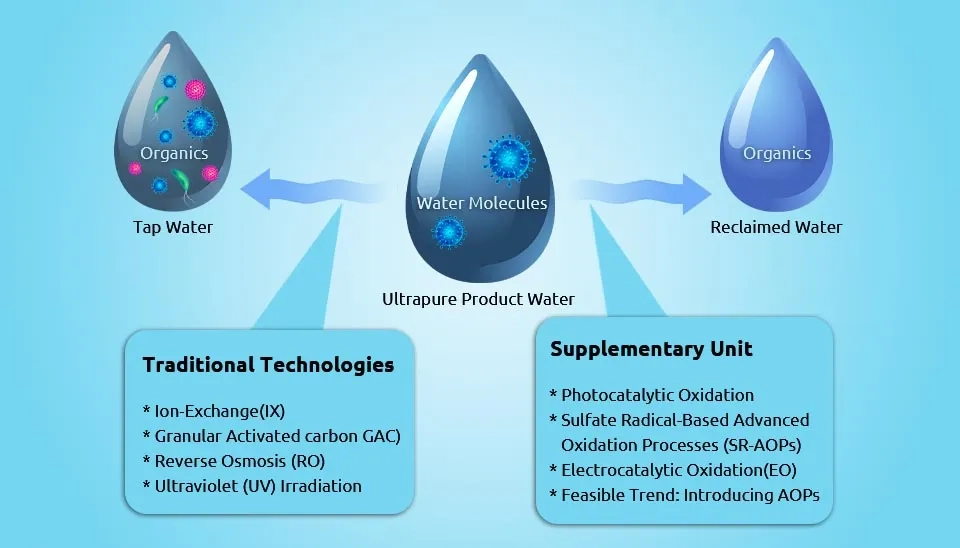

The results of recent studies show that using reclaimed water as raw water for UPW production is a very practical and feasible engineering solution to achieve sustainable utilization of water resources. However, in comparison with tap water, the urea is more than double in the reclaimed water, which is used to produce ultrapure water, and consequently, it cannot be effectively removed (Lefebvre, 2018; Wang et al., 2019).

4.2. Organic Matter Removal

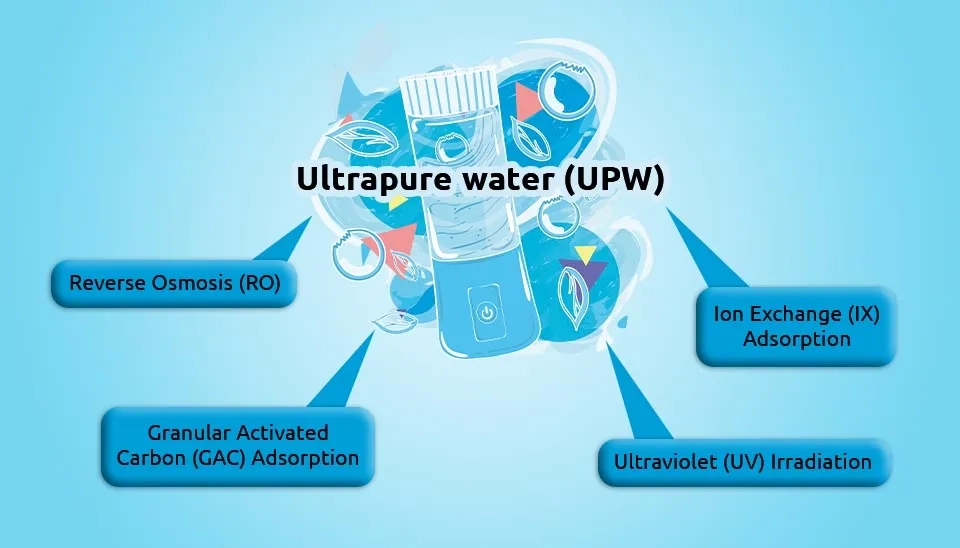

To ensure UPW standard, the production process should effectively remove small molecule organic compounds in the raw water which can be achieved using different approaches. Some of these processes for organic matter removal are Activated Carbon (AC) adsorption, ion-exchange (IX) adsorption, , Reverse Osmosis (RO), and Ultraviolet (UV) irradiation (wavelengths at 185 nm) (Choi and Chung, 2019; Choi et al., 2016; Zhao et al., 2019). However, it is still difficult to remove some small molecular organic pollutants by these methods. Studies have indicated that although a series of purification processes are contributed to UPW production, some organic matters like methanol, urea, and Isopropyl Alcohol (IPA), can still be present in the final effluent (de Abreu Domingos and da Fonseca, 2018; Lee et al., 2016).

Studies have shown that UV irradiation (185 nm) is effective in removing and deactivating some low molecular weight organic matters like isopropanol, methanol, and pathogens. In addition, Ultrafiltration (UF) technology is an efficient method for suspended microorganisms degradation. Moreover, RO, UV irradiation, and IX adsorption can remove dissolved macro molecular organic and inorganic pollutants (Sun and Chen, 2014; Matilainen and Sillanpää, 2010).

5. Ultrapure Water Production Technologies

There are many purification technologies involved in the ultrapure water production system. The detection and control of bacterial proliferation, organic pollutants, Total Organic Carbon (TOC), metallic contaminants, and anionic contaminants is vital for UPW production. In practice, adsorption, Reverse Osmosis (RO) (Malaeb and Ayoub, 2011), and Ultraviolet (UV) irradiation (Legrini et al., 1993), etc. are the main technologies used for organic matter removal during UPW production. Among these methods, the two-pass RO can significantly reduce the organic compound concentration in UPW (Lee and Kim, 2015).

However, it is not easy to achieve complete removal of small molecule organic pollutants in the water by using one technology, and it is more efficient to use a combination of methods including Activated Carbon (AC) (Lambert et al., 1996), RO, Ion Exchange (IX) (Humbert et al., 2005), and UV irradiation. Firstly, during the pretreatment stage, AC and UV are used to remove suspended solids and some macromolecular organic compounds. Then, by using IX and RO, the ultrapure water will be desalted, and finally, to enhance water quality in the polishing stage, UV and ultrafiltration are applied. Throughout a series of processes, advanced ultrapure water systems can effectively remove ions and organic compounds (Lee et al., 2020; Zhang et al., 2021). Depending on the type of raw water, product water quality specification, and applications, plant designs can be incorporated with each of these technologies (Singh, 2016).

5.1. Reverse Osmosis (RO)

In the last decade, with the development of membrane technology and a number of processes for achieving ultra-purity, reverse osmosis has become one of the main methods of UPW production. RO is known to be extremely effective in organic compound removal to obtain water with a maximum resistivity of 2 MΩ cm (Lee et al., 2016). This method is commonly used during the desalination and make-up stage. Since the polishing stage can not ensure the final quality of ultrapure water, the RO technology is needed to reject all impurities present in raw water. RO has been proven to be able to reject more than 80% of high-molecular-weight compounds (Yoon and Lueptow, 2005).

Selecting low temperature, high flux, RO membrane with high salt rejection are some factors that can improve the removal efficiency of low-molecular-weight organic matter by reverse osmosis process during UPW production (Lee and Kim, 2015). To optimize the UPW production system, Zhao et al. (2019) applied the two-pass RO process. Their results indicated that the two-pass RO process can reduce TOC concentration and the removal efficiency of selected organic matters can reach 60-95%. Moreover, the RO performance is highly related to the raw water quality. For example, using reclaimed water in UPW production affects the treatment efficiency of RO. Generally, it is not sufficient to rely solely on RO technology to achieve the final standards and desirable concentration required for UPW production.

5.2. Granular Activated Carbon (GAC) Adsorption

Granular activated carbon is mostly used in the pretreatment and desalination stage in the ultrapure production process, due to its high adsorption capacity, to remove macromolecular organic compounds, suspended solids, and ions. However, it has been found that GAC can not effectively remove some small polar molecules with high solubility, such as urea, isopropyl alcohol, etc. (Schmotzer et al., 2002).

Molecular polarity, size, charge, and solubility of organic compounds are some important factors affecting the adsorption capacity of GAC. In addition, other technologies are needed to facilitate the GAC adsorption, to efficiently remove small molecular organic compounds in the UPW production (Safwat and Matta, 2018). (For further insights, refer to this article “Article’s Title”)

5.3. Ion Exchange (IX) Adsorption

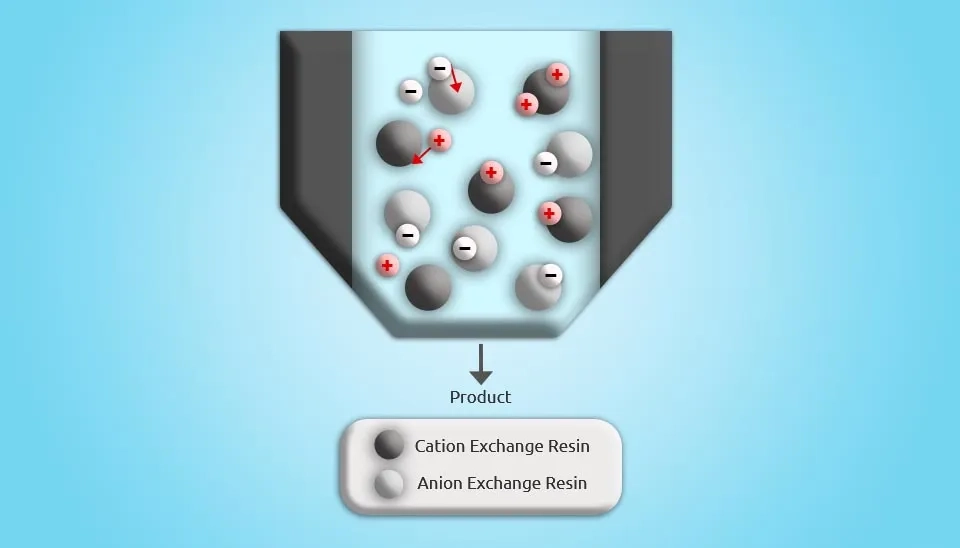

During the desalination stage of ultrapure water production, IX resin is commonly used, which makes the ion exchange technology necessary for the UPW production process. Almost all types of UPW production systems include ion exchange adsorption using IX resin to ensure that the final effluent quality of ultrapure water meets the standards. To remove impurities by using IX resins, anion resins that have OH- can exchange anions, and cationic resins that have attached H-can exchange cations in the water. Consequently, ions and organic matter in the water can be effectively removed and also the OH- and H- combined to form water molecules (Bennett, 2009).

The removal efficiency of neutral organic matter by IX resin is very limited due to the small number of charged organic compounds in the UPW and therefore, it is more difficult to remove urea (a kind of uncharged small molecular organic compound) by IX resin. Ion exchange resins remove undesirable ions through replacement by desirable ones. For example, if the regenerating solution is a strong acid like H2SO4 or HCl, the resin replaces cations with hydrogen ions as well as replacing metallic ions with hydrogen, which is known as hydrogen cycle cation exchange. In addition, it is more effective to combine IX technology with other methods or modify the existing IX resin materials to eventually reduce the number of organic pollutants in ultrapure water production (Singh, 2016). (For further insights, refer to this article “Article’s Title”)

5.4. Ultraviolet (UV) irradiation

The ultraviolet irradiation can be used as an alternative biocide. UV light with a wavelength of 185 nm produces oxidative ozone and hydroxyl radicals in water and as a result, it is capable of breaking down organic matter and inactivating bacteria (Collentro, 2014). Besides, the mutation of bacteria DNA caused by UV254 nm can hinder further cultivation of microorganisms. UPW production systems mostly use UV in the final stage during water disinfection. Moreover, UV irradiation is necessary at both pretreatment and polishing stages to enhance the removal rate of organic contaminants in ultrapure water production (Wammes et al., 2015).

According to Kutschera et al. (2009), UV185 has a high removal efficiency due to its direct oxidizing impact on organic compounds and also producing HO through synergistic action with water molecules, which accelerate the oxidation of organic matter. In addition, using multi-wavelength UV 185/254 nm can lead to a rapid decrease in TOC concentration. (For further insights, refer to this article “Article’s Title”)

6. Conclusion

Ultrapure water production is an important process for various industries and applications including semiconductor manufacturing, pharmaceutical industry, etc. It is essential to remove all pollutants like ions, organic matter, microorganisms, etc. in the UPW production process, and in this case, several technologies have been developed. The main technologies include reverse osmosis, activated carbon, ion exchange, and ultraviolet irradiation which can be used together to better achieve the purpose of ultrapure water production. However, further research should be carried out to optimize processes for a compact and high-performance UPW production system.