Primary treatment of wastewater is one of the four stages of wastewater treatment which reduces 30-40 % of Biological Oxygen Demand (BOD) and 45-70% of Total Suspended Solids (TSS) of wastewater (Tillman, 1992) and this reduction in oxygen demand reduces energy consumption, decreases the rate of operating difficulties for downstream biological treatment processes. As a result, its design criteria have a crucial impact on biological degradation efficiency and effluent quality. Sedimentation is the most common form of primary treatment. Therefore, the term primary sedimentation is generally used to describe this process. This is the oldest and most widely used unit operation in wastewater treatment.

This article provides detailed information about various methods used in primary treatment and the design criteria for sedimentation tanks. Lastly, the optimal operational conditions that operators must be familiar with are thoroughly described.

1. Three Methods of Primary Wastewater Treatment

The primary sedimentation is broadly divided into:

1.1. Conventional

In the conventional method, physical sedimentation is the key factor for removing suspended particles by retaining wastewater undisturbed between 2-12 or more hours. Heavy particles settled down at the bottom of the tank just by gravitational force. No chemicals or contributory equipment is used in this method.

1.2. Chemically Enhanced

Pre-aeration or chemical coagulation and precipitation enhance the performance of the primary sediment basin. For example, Jang et al., 2017 used this method to remove antibiotic genes from wastewater.

1.3. High-Rate Sedimentation Basins

High-rate sedimentation basins are designed in conjunction with Coagulation and Flocculation. To improve clarification, the sedimentation basin may use a liquid contact effect, an upright plate or tube transferor, and ballast flocculation. The majority of these systems use proprietary equipment which is sold under various configurations of brands (Metcalf & Eddy et al., 2014).

2. Design Criteria for Primary Wastewater Treatment

A common approach to designing a primary wastewater treatment basin is that this tank should be designed based on the oxidation capacity of downstream biological processes. The primary basin must be well designed because of its effective and important role in the whole system. For less operational costs than any other treatment process in use today, primary clarifiers can remove more BOD and solids than any other treatment process (Wahlberg, 2006).

In addition to de-gritted raw sewage, side streams that are recycled may also be received in primary basins. This side stream consists of rejects from Sludge Treatment Processing areas, filter backwash return, and waste-activated sludge leading to an increase in BOD, TSS, nitrogen, etc. so this side stream should be considered in sedimentation basin design.

When designing a Flocculent Settlement Basin, detention time becomes a crucial parameter. (Qasim 1999).

2.1. Design of Common Basin Configurations

The common types of primary basins are (1) circular, (2) rectangular, (3) square, and (4) multi-stack. Circular and rectangular tanks are the most common configurations. The choice of basin type depends on factors such as facility size, design criteria, local site considerations, experience and judgment of the design engineer, preference of local regulatory authorities, preference of operators and maintenance staff, and economic considerations (Davis, 2010).

2.1.1. Circular Sedimentation Basin Design Guideline

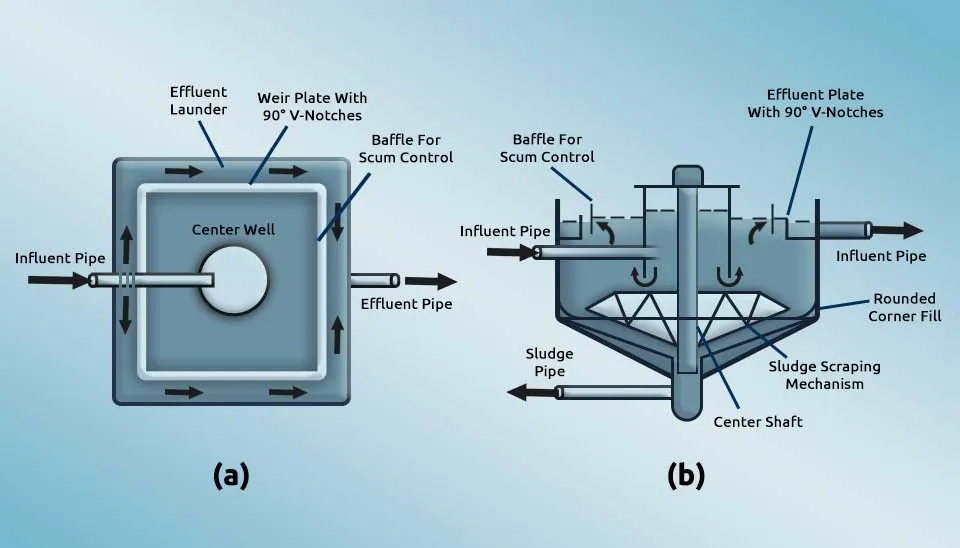

Theoretically, the flow pattern of a circular primary wastewater sedimentation tank is radial. The basin can be fed either in the central or around the periphery. For primary treatment, the center feeding type is more frequently used. Sewage can be introduced to the tank by either a pipe suspended from a bridge or one that is encased in concrete below the tank floor. A circular well feed is located at the center of the basin to distribute wastewater in all directions equally.

The typical dimensions of circular basins and their design guideline are provided in the figure.

2.1.1.1. Advantages and Disadvantages of a Circular Tank

Advantages:

Lower capital cost

More yard piping

Low upkeep cost

Ease of design and construction

Disadvantages

Short-circuiting

Low hydraulic detention efficiency

High risk of short-circuiting

Lack of scum control

Loss of sludge into the effluent

Table. 1. Components and dimensions of a circular basin (Qasim, 2018).

Parameter | Range | Typical |

Diameter, m (ft) | 3-60 (10-200) | 12-45 (40-1500) |

Side water depth, m (ft) | 3-5(10-16) | 4-4.5 (13-15) |

Bottom slope, m/m (ft/ft) | 1/16-1/6 | 1/12 |

Center well | ||

Diameter, % of basin diameter | 15-20 | 18 |

Depth, %of basin diameter | 25-50 | 35-40 |

The Bottom edge of the central wall m (ft) | 1 (3) below the Energy-Dissipating Inlet (EDI), or at least the depth of the tank | |

Max downward velocity in central well m/s (ft/s) | ≤0.75 (2.5) | - |

Freeboard, m (ft) | 0.5-0.7 (1.5-2) | - |

Sludge collector |

| |

Travel Speed (rpm) | 0.02-0.06 | 0.03 |

Tip speed m/min (ft/min) | ≤10 (30) | 3 (10) |

2.1.2. Rectangular Settlement Tank

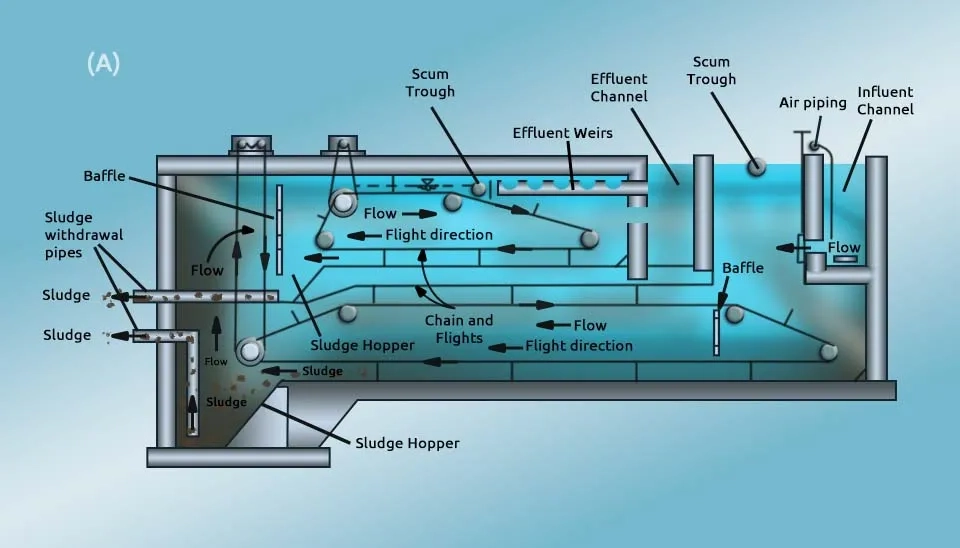

To ensure that standard-size equipment is readily available, the dimensions of a rectangular primary wastewater treatment tank are chosen. Compared to circular basins, rectangular basins have a wider flow path. The distribution of flows in rectangular basins is crucial. In the range of 3 to 9 m per minute, and 10 to 30 feet per minute, the horizontal component of velocity should be maintained.

2.1.2.1. Advantages and Disadvantages of a Rectangular Tank

Advantages

Less area requirement

Low cost

Easy control odor

Low risk of short-circuiting

Low inlet–outlet losses

Low power consumption for sludge collection mechanisms

Disadvantages

Possible dead spaces

Sensitive to flow surges

Restricted in width

Requirement of multirow weirs to achieve low weir loading rates

High upkeep and maintenance costs.

The dimensions and design guidelines of the rectangular basins are given in the table below.

Table. 2. Dimensions of rectangular sedimentation basin

Parameter | Range | Typical |

Length, m (ft) | 15-90 (50-300) | 30-60 (100-200) |

Width, m (ft) | 6-24 (20-80) | 6-9 (20-30) |

Side water depth, m (ft) | 3-5 (10-16) | 3.7-4 (12-13) |

Length- to Width, ratio | 1.5- 15:1 | 4-5:1 |

Length-to-depth, ratio | 5- 25:1 | 10-18:1 |

Bottom slope, m/m (ft/ft) | 6-15 | 8 |

2.1.3. Square Tanks

A square tank is a modification of a circular tank. They're much like a circular tank in the hydraulic sense. In general, the sludge removal equipment used in them is similar to that of circular tanks. It might be difficult to remove the settled solids from corners. To avoid the accumulation of solids, corner sweeping equipment and rounding in corners shall be applied. As a primary clarifier, square tanks are rarely used. Details of the layout and the sectional Square tanks are shown in the image.

2.1.3.1. Advantages and Disadvantages of Square Tank

Advantages:

Low construction materials due to having common walls

Formation of dead space is less possible

Small footprint

Disadvantages:

Removing the settled solids from corners is challenging and requires extra equipment.

Due to underground piping, it is difficult to manage fouling

High risk of short-circuiting

2.1.4. Series-Flow Multi-Level Tanks Design Guideline

Stacked or multi-level primary treatment basins have been used for primary wastewater treatment, in areas where land is not available. The design criteria are similar to those of conventional primary tanks.

2.1.4.1. Series-Flow

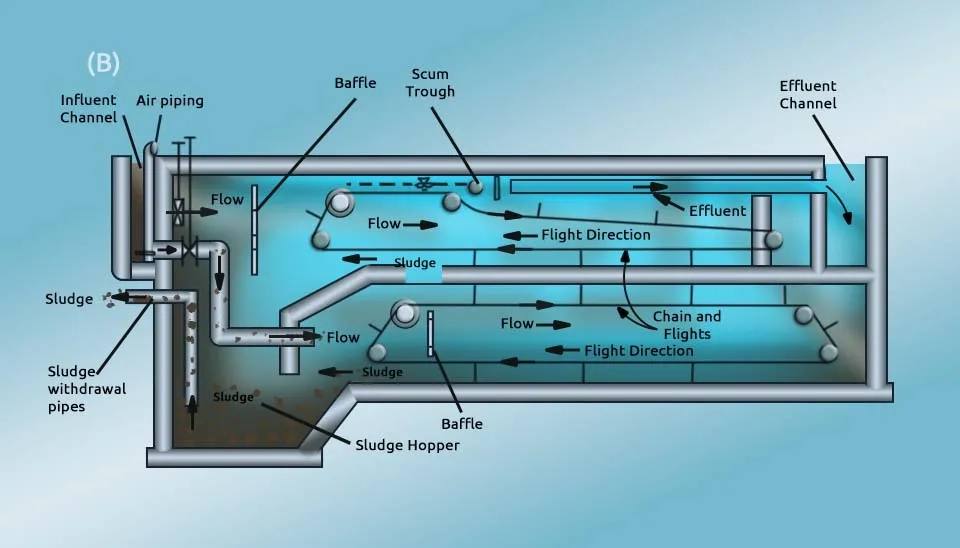

In a series-flow basin, the influent enters the lower tray, goes up into the secondary tray on the far end, and travels in the opposite direction. The effluent exits from the upper tray. System components and flow schematics of a two-tray series-flow basin are shown in the figure below.

2.1.4.2. Parallel-Flow Multi-level Tanks

In the parallel-flow basin, the split influent enters separately in the upper and lower trays at the same end and moves longitudinally. Influent baffles on both sides ensure a smooth flow and minimize turbulence. The components and flow charts of two parallel-flow basins are shown below.

2.1.4.3. Advantages and Disadvantages of Stack Tanks

Advantages

Compact and save space

Less piping and pumping requirements

Better control of odors and volatile organic compounds emission.

Disadvantages

High construction cost

Complex structural design

Difficulties in observation of lower tray

High operation and maintenance costs.

3. Equipment of Primary Tanks

Some of the critical equipment that must be installed in primary treatment tanks:

3.1. Baffle

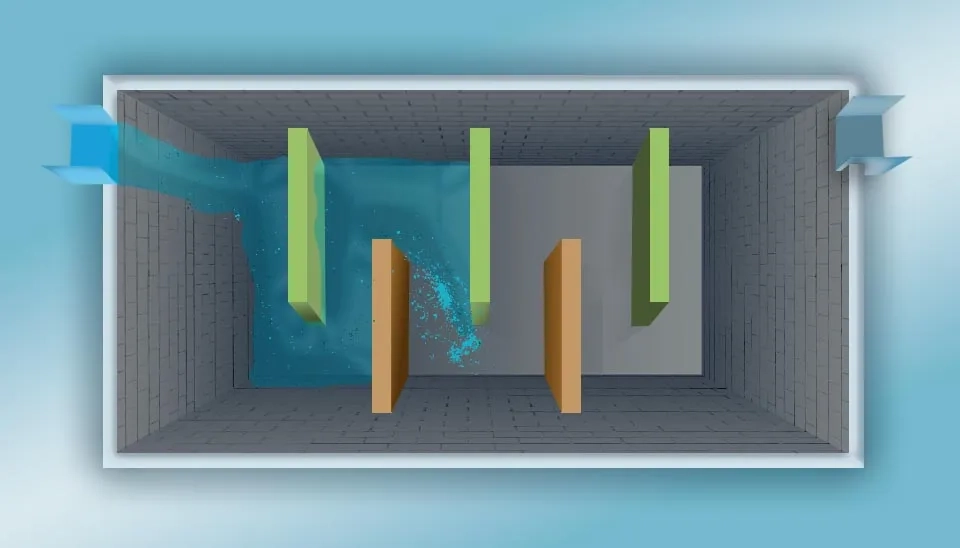

In rectangular basins, a baffle will be installed to distribute wastewater in all directions. This baffle longs till the bottom of the basin.

3.2. Scum Removal Device

Scum is typically pushed toward the effluent end by the flights of the sludge mechanism during its return travel. All effluent weirs have baffles to stop the loss of scum into the effluent. The scum may be scrapped manually or mechanically up an inclined apron (Rosa et al., 2017).

3.3. Sludge Collection System

Sludge collection systems in rectangular tanks can include either a Conveyor Chain or a Moving-Bridge Drive Scraper

The conveyor chain arrangement has easy installation, low power consumption, and is efficient for scum collection. It's suitable for heavy sludge. High maintenance costs for chains and flights, as well as sludge removal mechanisms, are the main problems of this system.

The moving-bridge-type sludge collectors cross the length of the tank. The wheels run on rails that are attached to the footing walls along each side wall of the basin. Advantages include no contact with wastewater, ease of repair and replacement, long operation life, and low maintenance cost. Disadvantages include high power consumption and wind may cause the breakdown of the system.

In circular tanks sludge scraping mechanisms are installed with a radial arm and plows set at an angle. The bottom of the tank is sloped to form an inverted cone.

4. Conclusion

In this article, the World Water team provides complete information about the primary treatment of wastewater. This article discusses various methods of primary sedimentation for this stage of wastewater treatment. As already you know conventional settling is the common method of sedimentation and other processes such as high rate or chemically enhanced are in use for Industrial Wastewater Treatment. There are five kinds of basins: circular, rectangular, square, parallel, and series flow. Multi-level tanks are mostly used in compact wastewater treatment plants. On the other hand, circular and rectangular are common for larger sewage treatment plants.